Intelligent back pressure type energy-saving flushing valve

A smart anti-pressure and flush valve technology, applied in the field of sanitary products, can solve the problems of low structure utilization optimization rate, narrow application range, and increased use burden, so as to improve the structure utilization optimization rate and avoid excessive flushing noise. Large, to avoid the effect of excessive flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

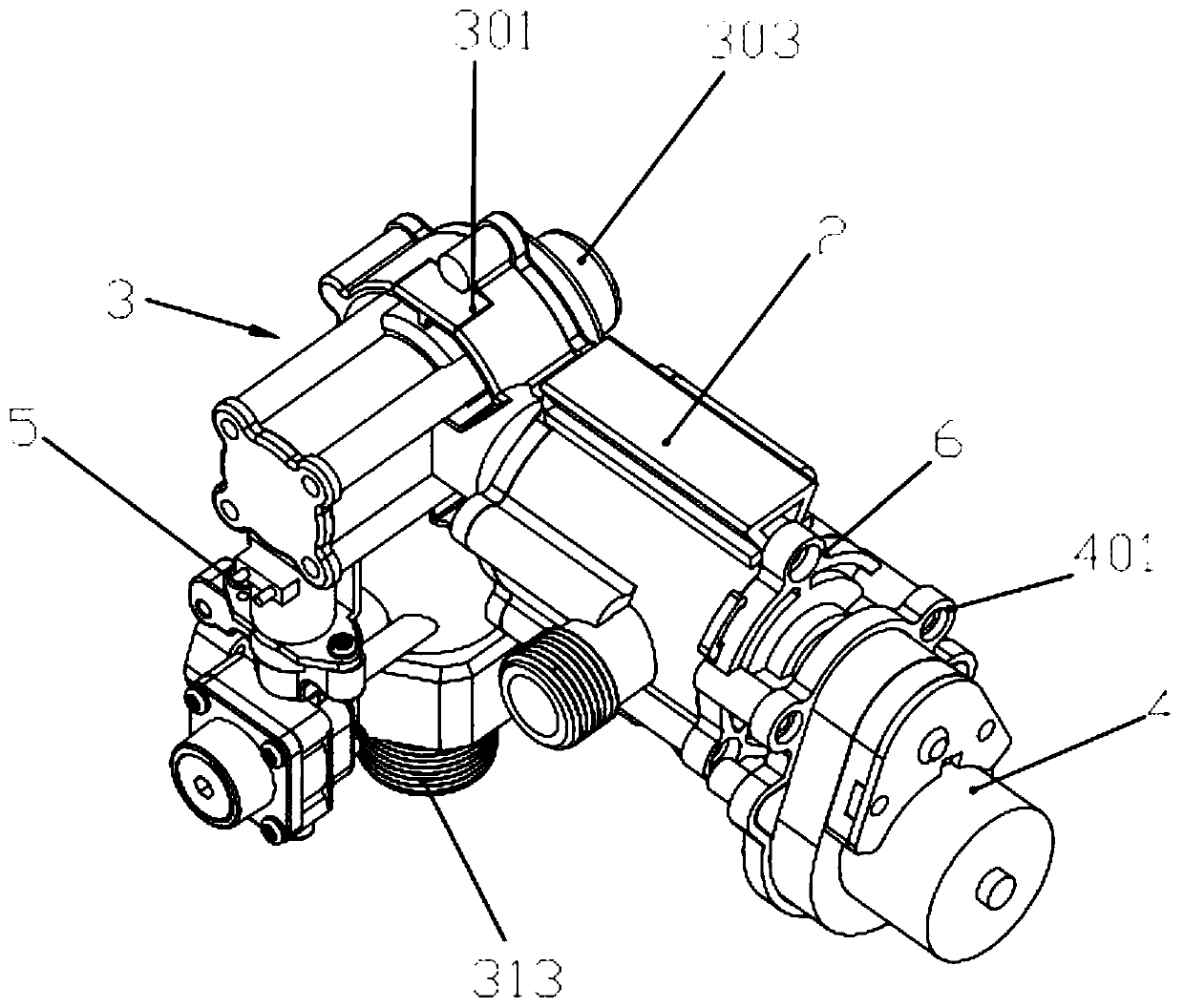

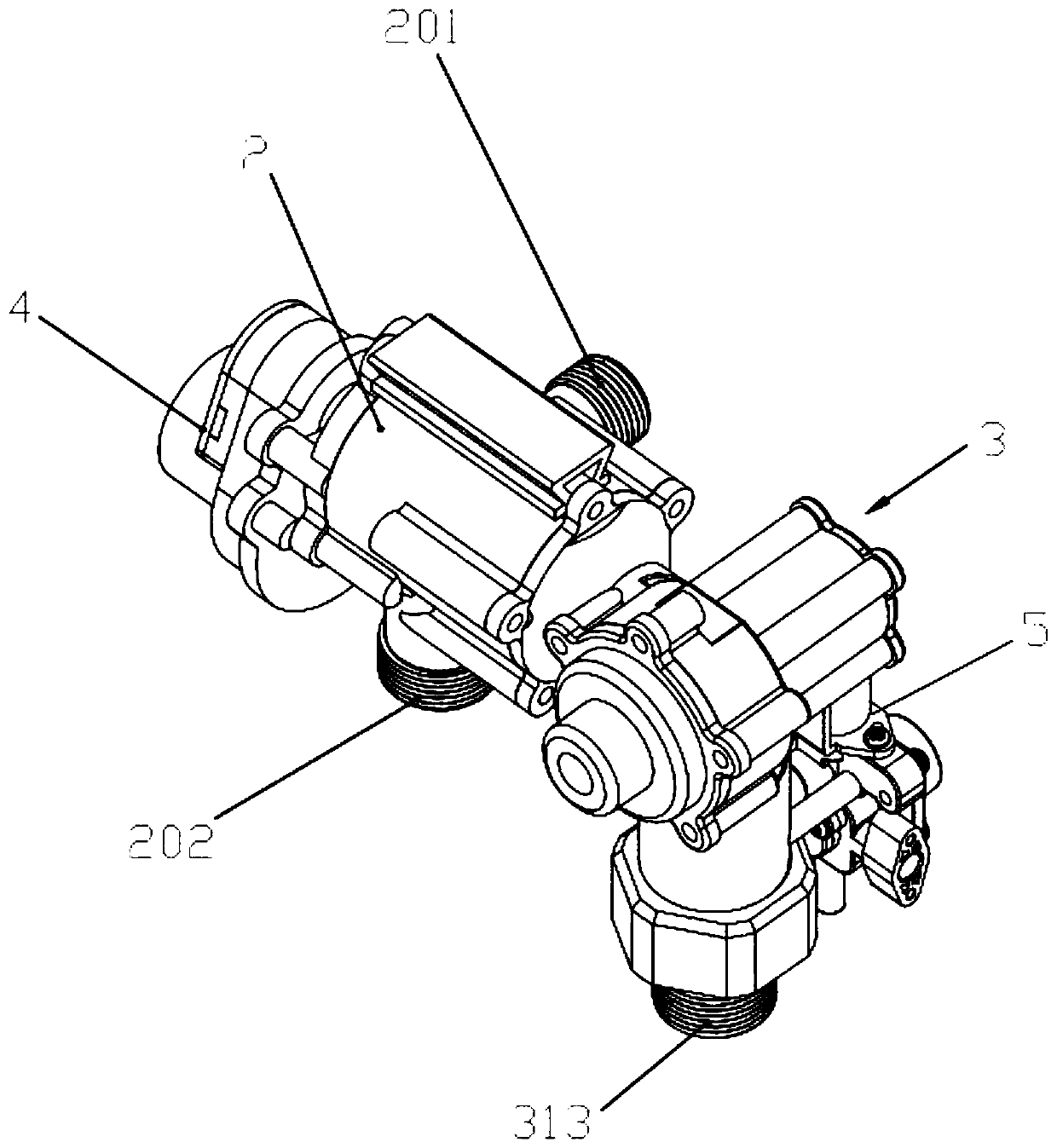

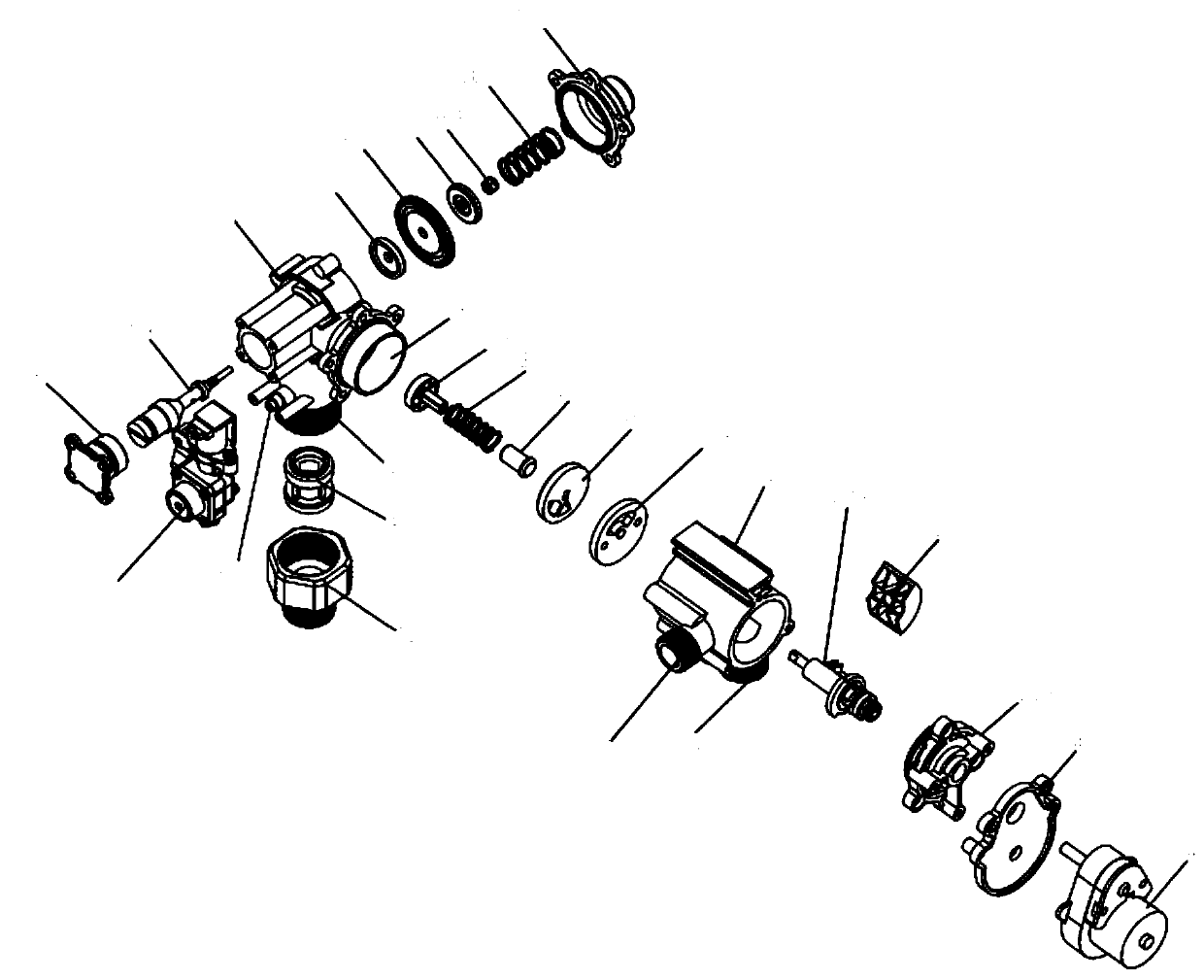

[0028] In this embodiment, refer to Figure 1 to Figure 6 , an embodiment of the present invention, an intelligent anti-pressure energy-saving flush valve, the flush valve is installed inside the toilet 1, the flush valve includes a flush valve body 2, a motor 4, a solenoid valve 5 and a constant Pressure valve 3, the constant pressure valve 3 includes a four-way water inlet connection elbow 301, a gland 302 and an end cover 303, the inside of the four-way water inlet connection elbow 301 has an assembly space, and a valve is installed in the assembly space Stem 304, the head end of the valve stem 304 is installed in the four-way water inlet connection elbow 301 through the gland 302, and the valve stem 304 is provided with a lower pressing piece 305, a diaphragm 306, an upper pressing piece 307, a nut 308 and a spring 309, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com