Small-scale two-stage rocket combination ramjet

A ramjet, small-scale technology, applied to combined engines, ramjet engines, engine components, etc., can solve problems such as difficulty in generation, reduced suction capacity, and affecting the starting ability of the intake port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

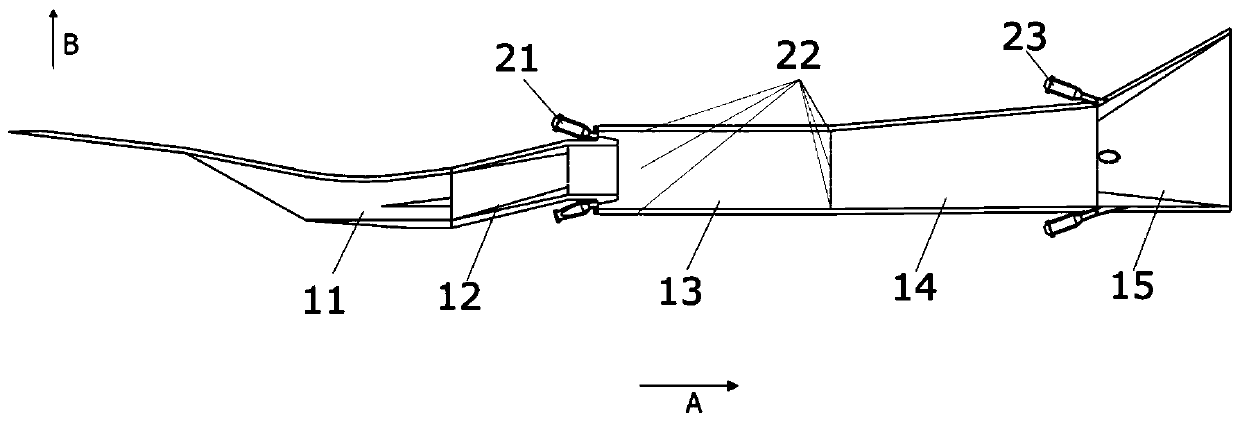

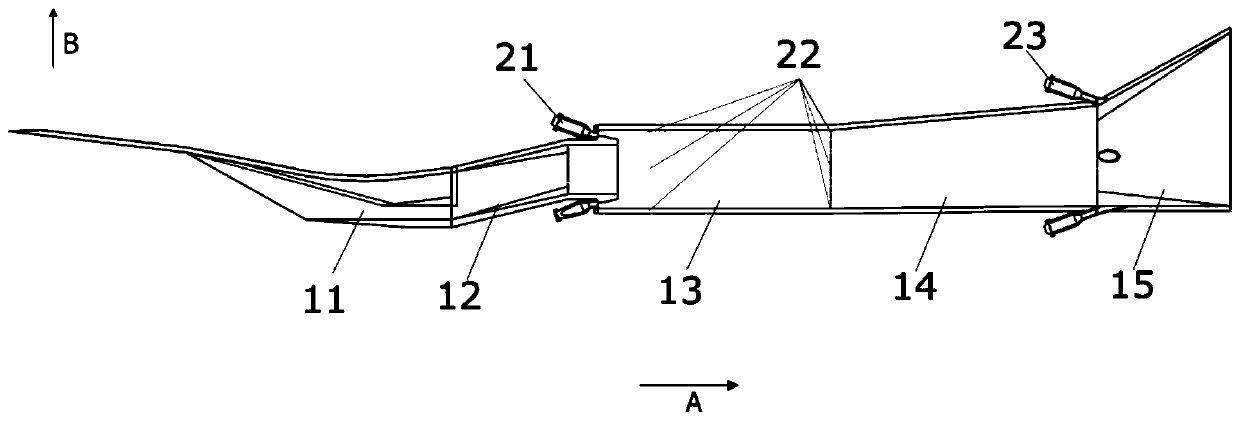

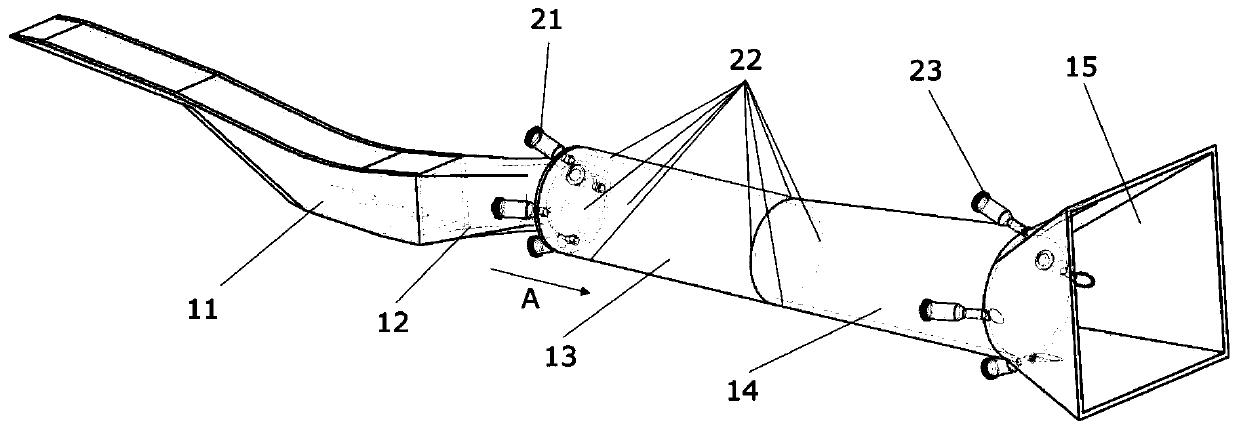

[0022] See Figure 1-3 As shown, the present invention provides a rocket-based combined cycle engine, comprising an air inlet 11, an isolation section 12, a first-stage combustion chamber 13, a second-stage combustion chamber 14, an exhaust nozzle 15, a first rocket unit 21, a fuel Injection hole 22 and second rocket unit 23 .

[0023] The intake passage 11, the isolation section 12, the first-stage combustion chamber 13, the second-stage combustion chamber 14 and the tail nozzle 15 are connected in sequence, specifically, the intake passage 11, the isolation section 12, the first-stage combustion chamber 13, The second-stage combustion chamber 14 and the tail nozzle 15 are connected by flange connection or welding. The air flow flows from the air inlet 11 through the isolation section 12, the first-stage combustion chamber 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com