Rotary cap locking device

A technology of flap lock and lock bar, which is applied in the aviation field, can solve the problems that the fastener connection cannot meet the requirements, waste time, and is easy to fail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

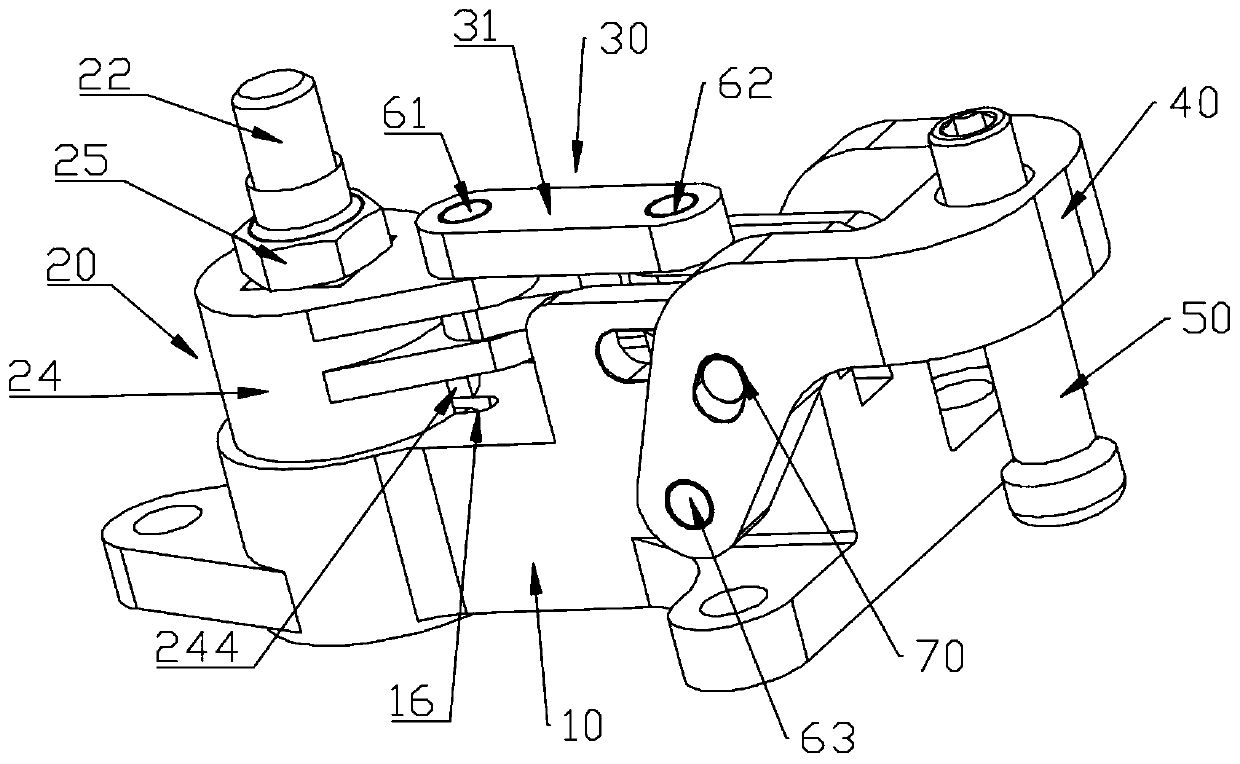

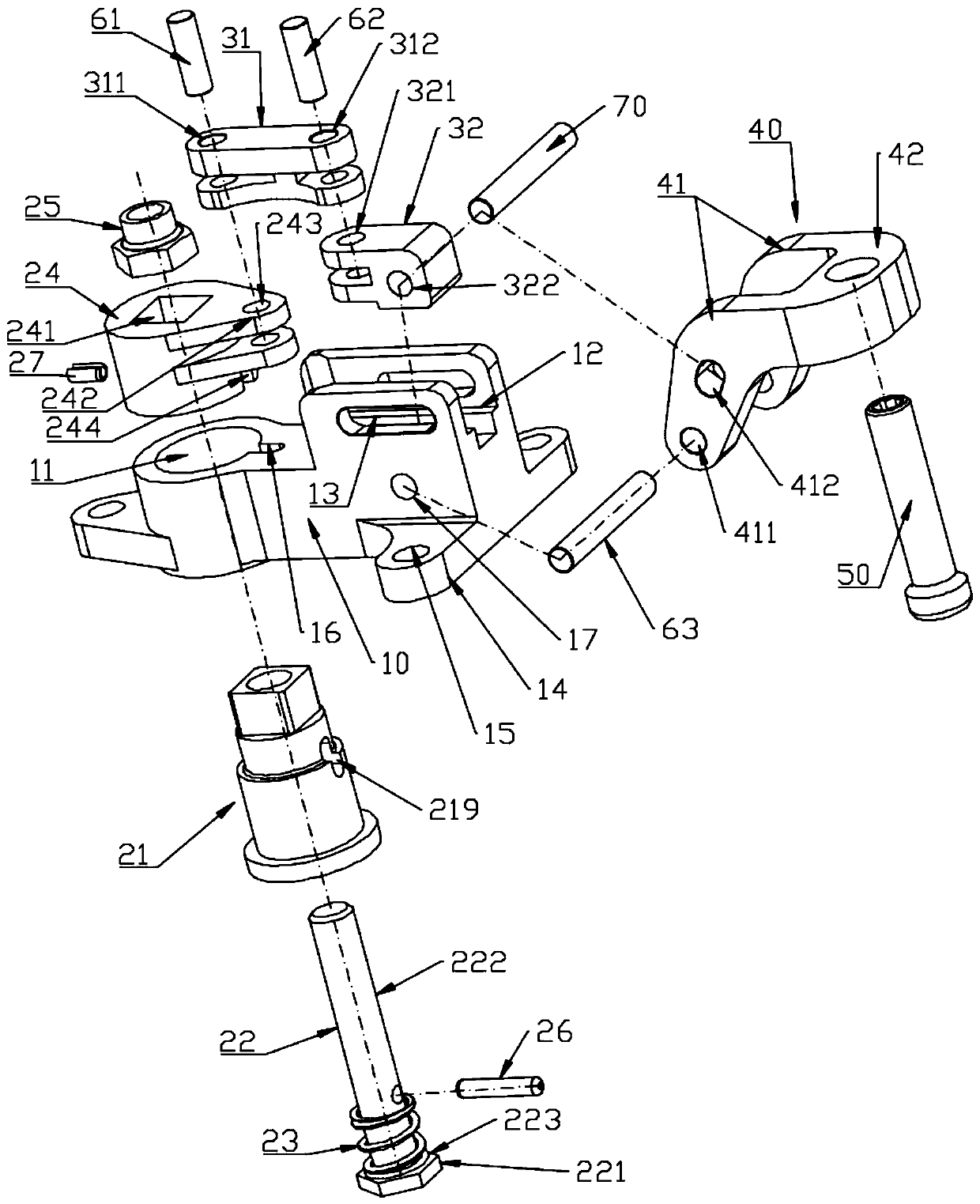

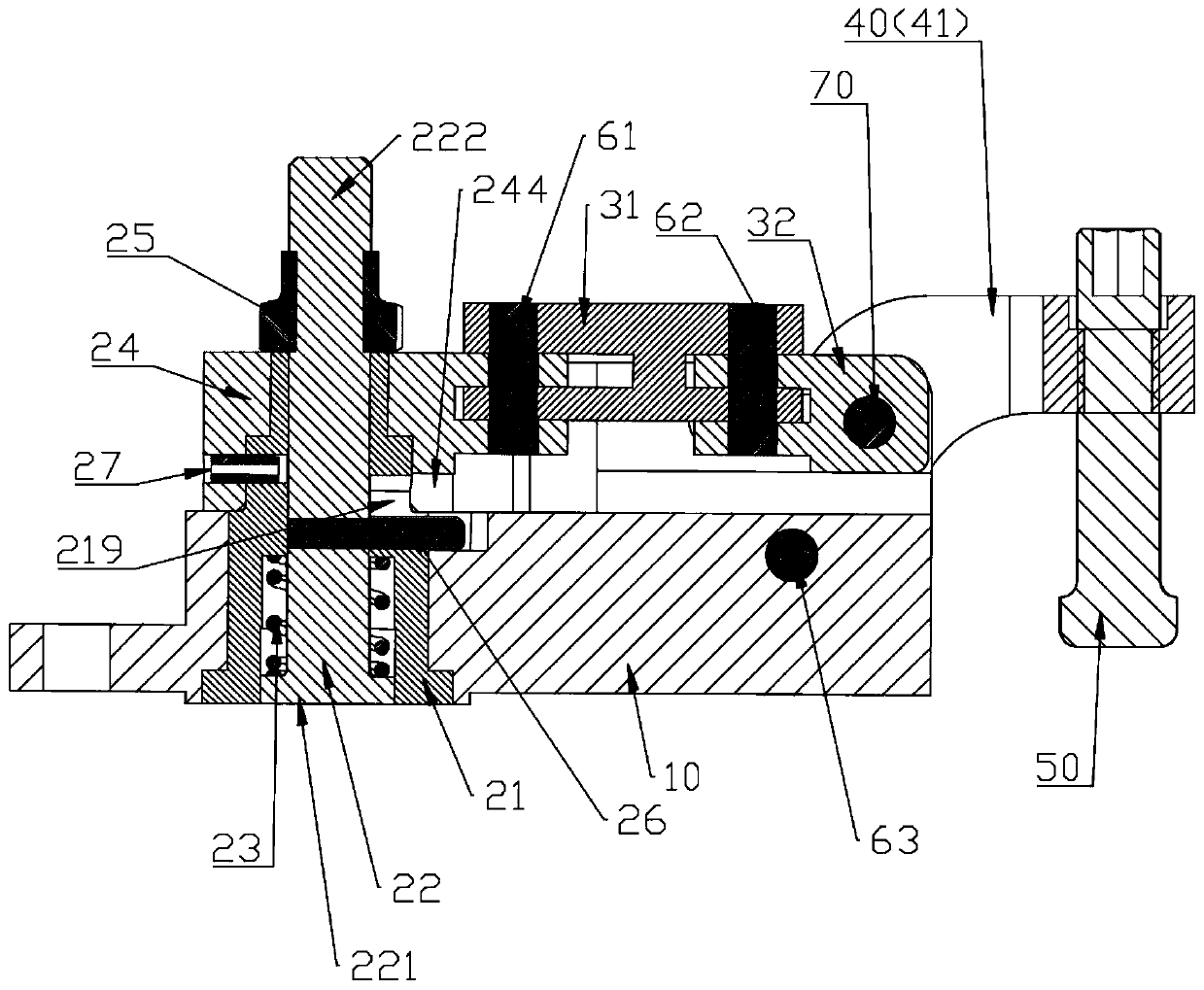

[0025] like Figure 1 to Figure 8 As shown, the rotary cover lock device of the present invention includes a base 10 , a rotating assembly 20 , a crank-slider mechanism 30 , a support 40 and a lock lever 50 . The rotating assembly 20 is rotatably connected to the base 10 and is connected to the crank-slider mechanism 30 . The crank-slider mechanism 30 is connected with the support 40 , which can convert the rotation of the rotating assembly 20 into a linear motion, thereby driving the support 40 to rotate around the base 10 , so that the locking rod 50 is released from the original position for locking or unlocking.

[0026] like Figure 1 ~ Figure 4 As shown, the base 10 is provided with a rotating shaft hole 11 for installing the rotating assembly 20 . The shaft hole 11 is a cylindrical through hole. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com