Preparation method of caramel inflaming retarding liquid and method for inflaming retarding finishing of wool fiber product

A technology of wool fiber and flame retardant liquid, which is applied in the direction of flame retardant fiber, fiber treatment, animal fiber, etc., can solve the problems of pollution, formaldehyde generation, human hazards, etc., and achieve short process, excellent flame retardant performance, and economic cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

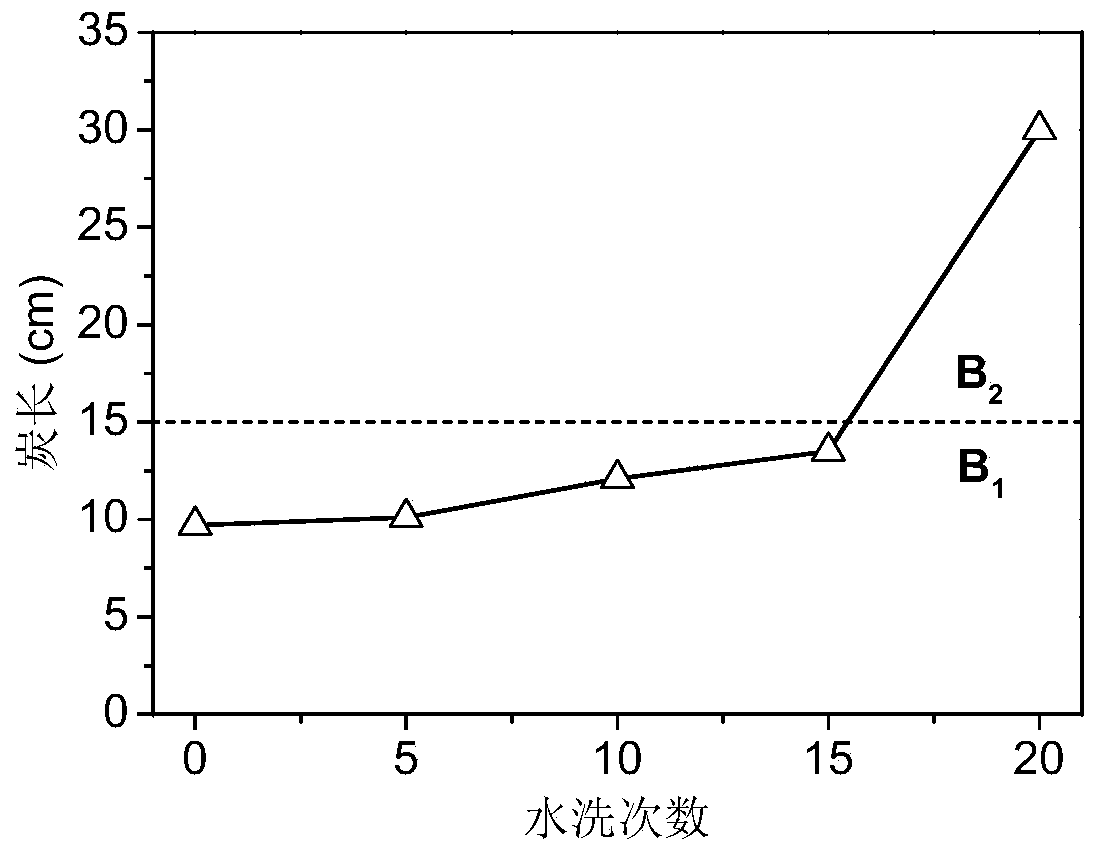

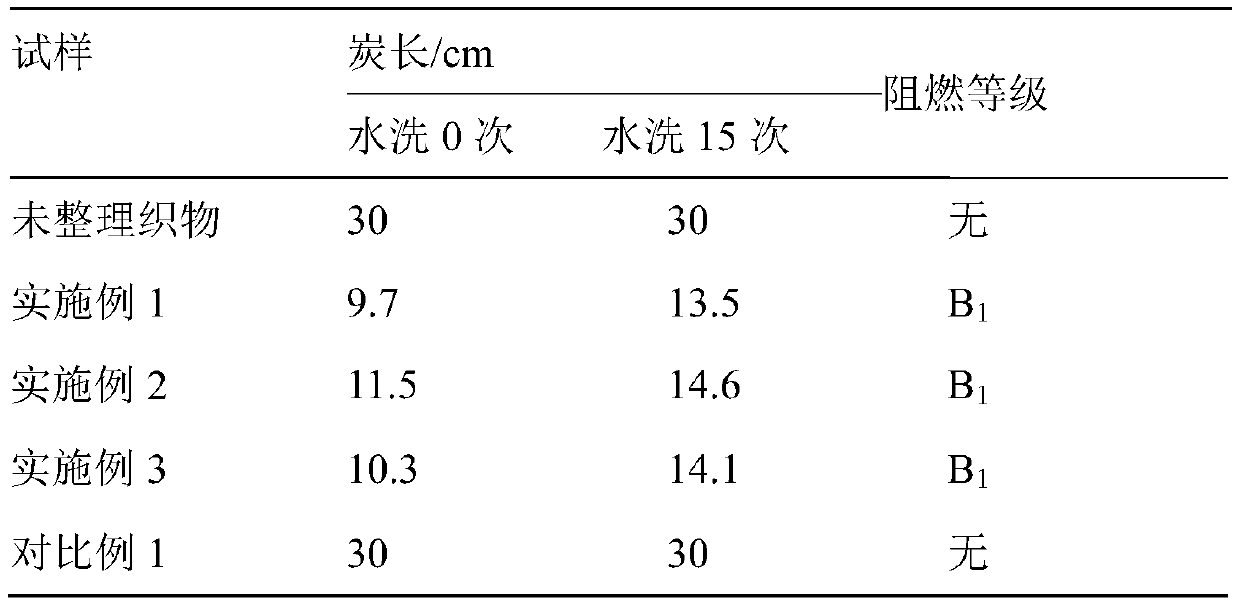

Embodiment 1

[0038] (1) Preparation of caramel flame retardant solution: first dissolve glucose in 100mL water to obtain a solution with a concentration of 10wt%, then use polypropyleneimine polymer to adjust the pH value of the solution to 12.0, and heat the solution to 95°C for 120min , to prepare caramel flame retardant liquid;

[0039] (2) Preparation of flame retardant wool fabric: use dilute sulfuric acid to adjust the pH value of the caramel flame retardant solution obtained in step (1) to 3.0, soak the wool fabric in the caramel flame retardant solution, raise the temperature to 98°C, keep it warm for 10 minutes, and then Squeeze excess water, dry at 80°C, and then bake at 145°C for 3 minutes to obtain a flame-retardant wool fabric.

Embodiment 2

[0044] (1) Preparation of caramel flame retardant solution: first dissolve sucrose in 100mL of water to obtain a solution with a concentration of 5wt%, then use polypropyleneimine polymer to adjust the pH value of the solution to 10.0, and heat the solution to 80°C for 90min , to prepare caramel flame retardant liquid;

[0045] (2) Preparation of flame retardant wool fabric: use dilute sulfuric acid to adjust the pH value of the caramel flame retardant solution obtained in step (1) to 4.0, immerse the wool power textile in the caramel flame retardant solution, raise the temperature to 90°C, and keep it warm for 10 minutes , and then squeezed out excess water, dried at 60°C and then baked at 140°C for 2 minutes to obtain a flame-retardant wool fabric.

Embodiment 3

[0047] (1) Preparation of caramel flame retardant solution: first dissolve sucrose in 100mL of water to obtain a solution with a concentration of 7.5wt%, then use polypropyleneimine polymer to adjust the pH value of the solution to 11.0, and heat the solution to 90°C to keep it warm 70min, prepared caramel flame retardant liquid;

[0048] (2) Preparation of flame retardant wool fabric: use dilute sulfuric acid to adjust the pH value of the caramel flame retardant solution obtained in step (1) to 3.5, soak the wool fabric in the caramel flame retardant solution, raise the temperature to 85°C, keep it warm for 25min, and then Squeeze out excess water, dry at 70°C, and then bake at 150°C for 2 minutes to obtain a flame-retardant wool fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com