Application of pyroelectric material

A technology of pyroelectric and ceramic materials, applied in applications, electrical components, household appliances, etc., can solve the problems of pyroelectric materials containing lead and unable to carry out intelligent management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

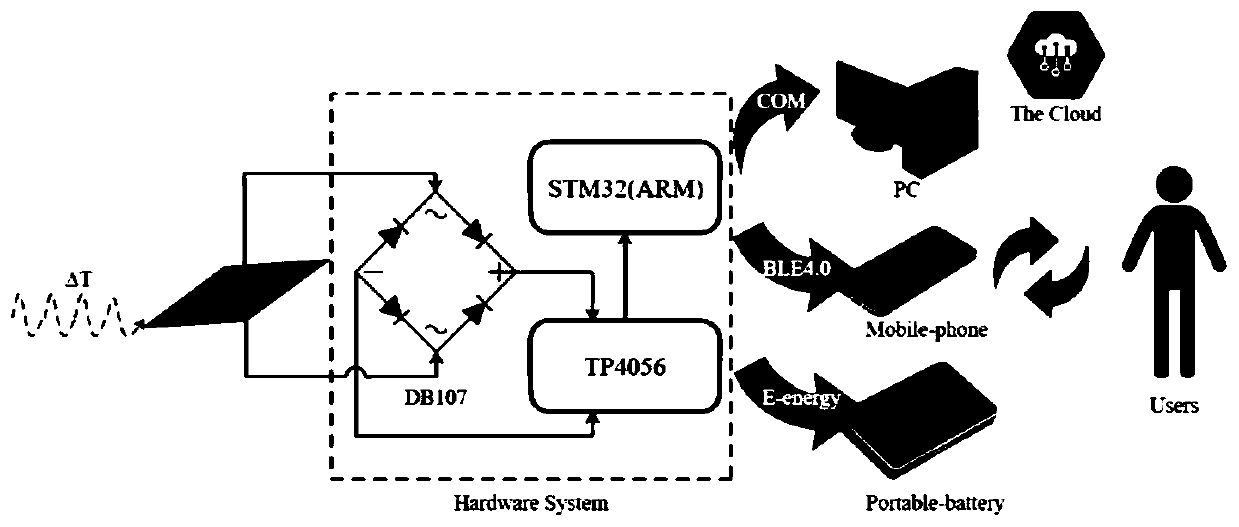

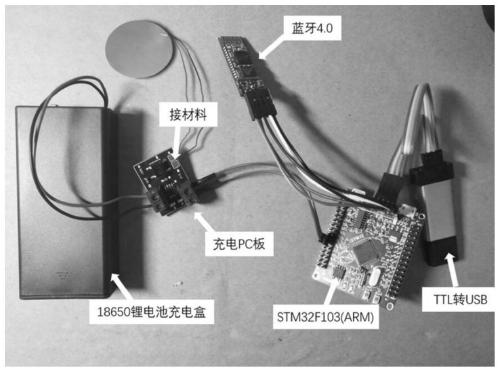

Method used

Image

Examples

Embodiment 1

[0046] Preparation and application of non-oriented porous zirconium barium perotitanate ceramic material,

[0047] Use analytical grade (Sigma Aldrich) BaCO 3 (99%), CaCO 3 (99%), TiO 2 (99.9%) and ZrO2 (99%) as raw materials, weighed according to the stoichiometric ratio; after ball milling the weighed material for 4h, mix well; the mixture was calcined at 1200°C for 3h, and then additionally ball milled for 24 hours;

[0048] Mix the ground mixture powder with ethanol for 12 hours, and divide it into 5 parts, add different contents of pore-forming agent corn starch, and then mix them with 1wt.% PVA binder; after drying, the powder is subjected to uniaxial Cold pressing to form pellets with a diameter of 13 mm and a thickness of 1.5 mm; the cold pressing pellets are first heated to 600 ° C for 3 h to remove organic additives, and then sintered at 1400 ° C for 4 h to obtain the final five porous zirconium barium perotitanate ceramics material samples;

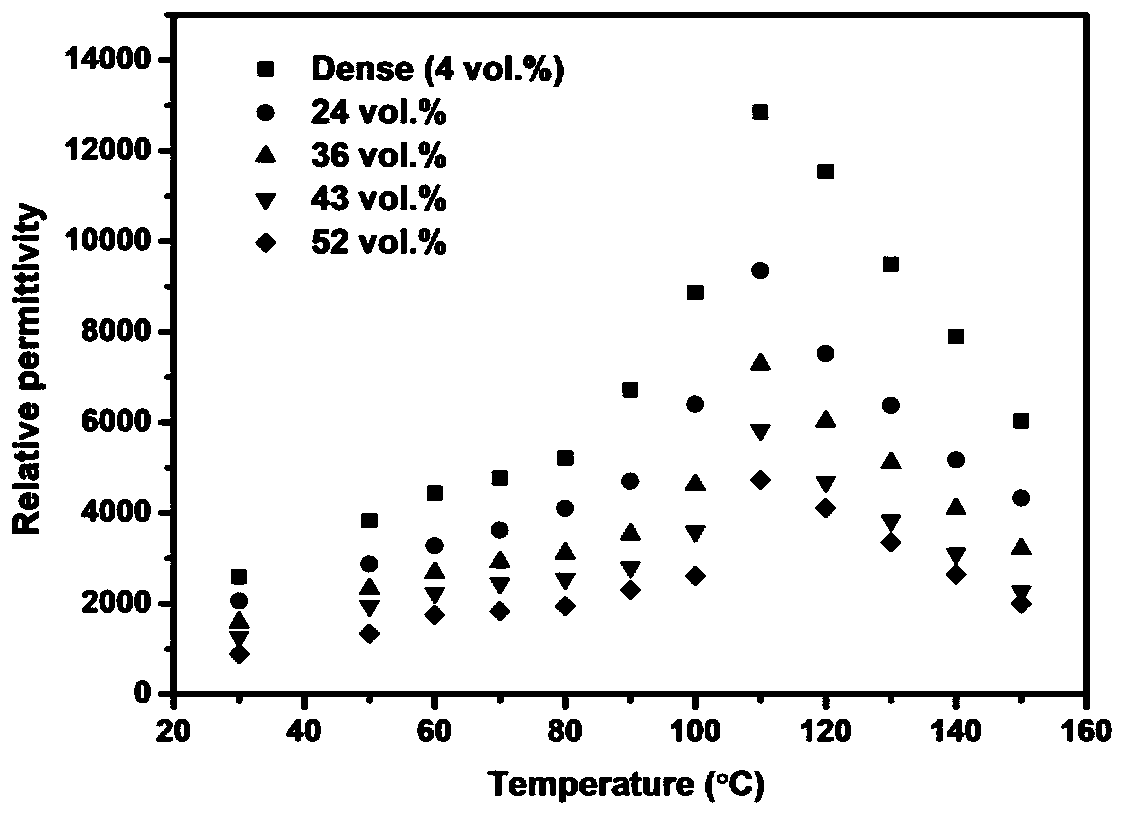

[0049] Wherein, whe...

Embodiment 2

[0061] Add BCZT ceramic powder (with an average particle size of 0.6 microns) to 5 parts of water with different contents, mix polyvinyl alcohol and ammonium polyacrylate to obtain 5 parts of suspension, place the suspension in molds respectively, and then place the mold in Carry out directional freezing in a liquid nitrogen environment, wherein the temperature of the cold end is -100°C, the temperature of the hot end is 6°C, and the freezing rate is controlled to be 3°C / min; the ice blank formed by directional freezing is dried, and the dried- 60°C, pressure 3Pa

[0062] To obtain a green body with oriented pores, the green body was first heated to 600° C. for 3 hours, and then heated to 1400° C. for 4 hours for calcination, and 5 parts of porous zirconium barium perotitanate ceramic materials were obtained.

[0063] Among them, the BCZT ceramic powder is unidirectionally pressed and sintered to obtain a dense barium zirconium perotitanate ceramic material with a porosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com