A high-purity and high-density a/b-site multi-ion co-doped bismuth ferrite-based ceramic and its preparation method

A bismuth ferrite-based, multi-ion technology, applied in the field of bismuth ferrite-based ceramics and its preparation, can solve the problems of poor phase purity, large ceramic leakage current, and low densification degree of bismuth ferrite ceramics, so as to facilitate the densification of ceramics Minimize and refine powder size, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

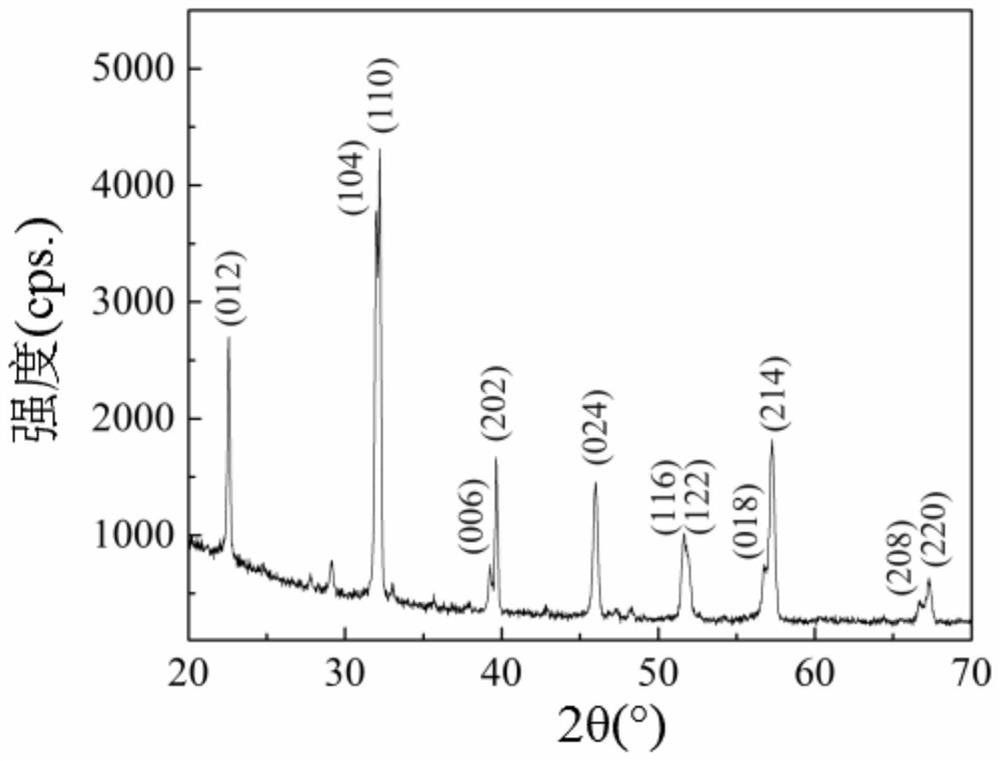

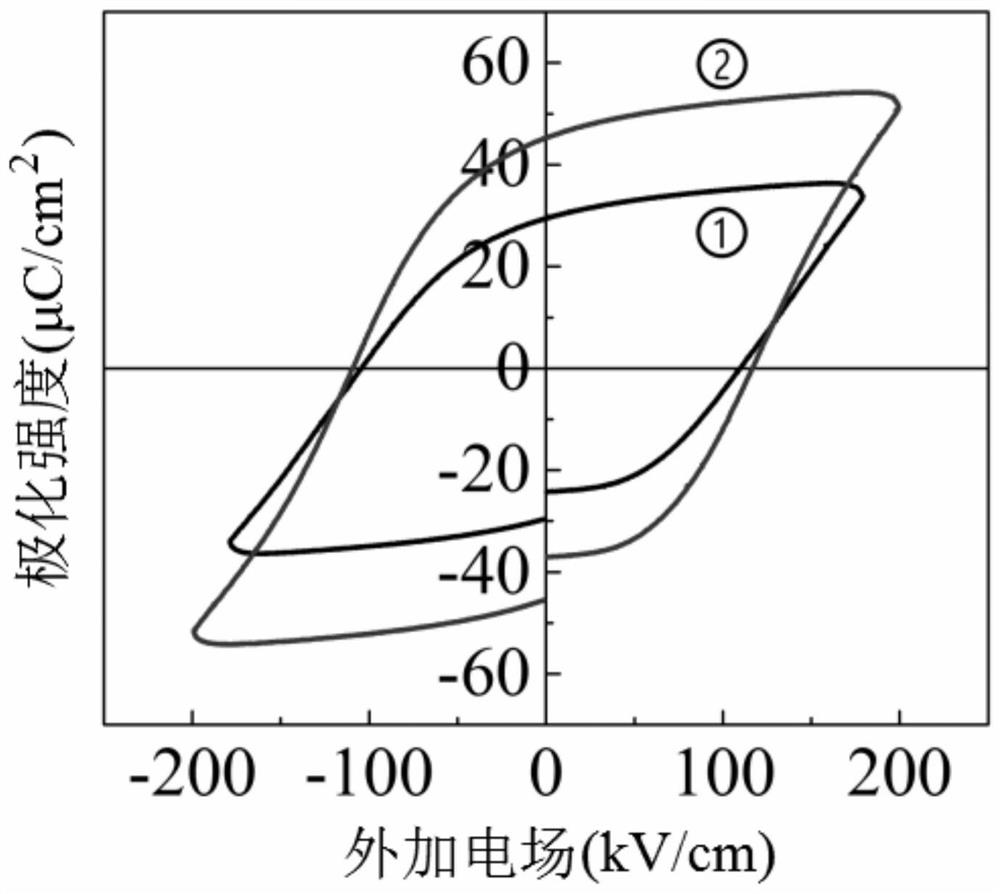

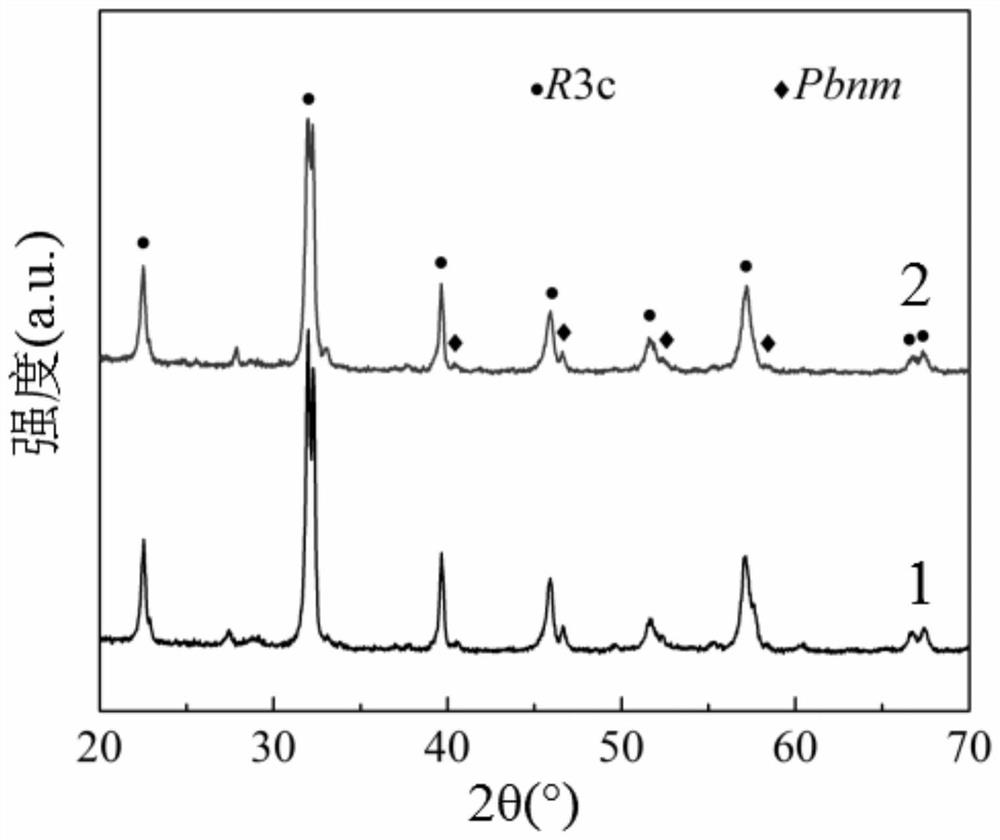

[0040] Embodiment 1: This embodiment is a high-purity and high-density A / B-site multi-ion co-doped bismuth ferrite-based ceramics. The general chemical formula is: Bi 1-x Re x Fe 1-y B y o 3 , wherein 0

specific Embodiment approach 2

[0041] Specific embodiment two: This embodiment is a preparation method of a high-purity and high-density A / B-position multi-ion co-doped bismuth ferrite-based ceramics, which is completed in the following steps:

[0042] 1. Weighing:

[0043] ①, according to the general chemical formula Bi 1-x Re x Fe 1-y B y o 3 Weigh bismuth oxide, iron oxide, rare earth oxide and high-valent transition metal oxide powder; where 0

[0044] ②, weigh bismuth oxide again;

[0045] The molar ratio of the bismuth oxide weighed in step 1.2 to the bismuth oxide weighed in step 1. is (0.01~0.1):1;

[0046] ③. Put the bismuth oxide, iron oxide, rare earth oxide and transition metal oxide powder weighed in step 1 ① and step 1 ② into the ball mill pot, then add ball milling medium absolute ethanol and balls, and use a high-energy planetary ball mill Grinding balls and mixing to obtain a ball-milled mixture;

[0047] 2. Dry the mixture after ball mill...

specific Embodiment approach 3

[0059] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the ball-to-material ratio in described step 1.3. It is 12h ~ 24h.

[0060] Other steps are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com