Steam rotary sodium sulfate drying system and method

A sodium sulfate drying and sodium sulfate technology, applied in the direction of alkali metal sulfite/sulfate dehydration, etc., can solve the problems of inability to break through mass production, high equipment maintenance costs, and affecting production efficiency, so as to facilitate production quality, Improve drying efficiency and effect, reduce maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

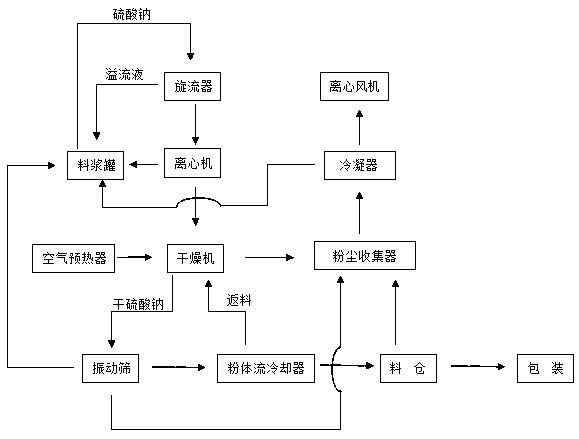

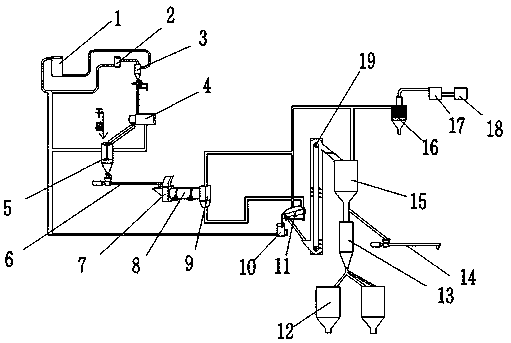

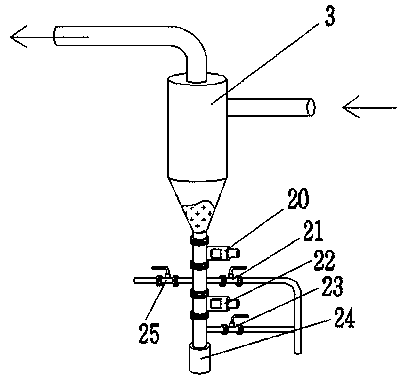

[0043] As shown in the drawings: a steam rotary sodium sulfate drying system, including a solid-liquid separation unit, a drying unit and a collection unit, the sodium sulfate slurry is separated from the solid-liquid by the solid-liquid separation unit, and the separated solid is dried by the drying unit. The solid-liquid separation unit includes a cyclone 3, a centrifuge 4 and a conveying chute. After the slurry is initially separated by the cyclone 3, it is separated from the solid-liquid by the centrifuge 4. The separated solids pass through the chute After entering the drying unit, the liquid separated by the cyclone 3 and the centrifuge 4 is returned to the sodium sulfate slurry tank 1.

[0044] This program has effectively broken through the mass production of sodium sulfate, with an output of at least 20 tons per hour, which effectively improves the drying efficiency and effect of sodium sulfate, improves the quality of sodium sulfate products, and solidifies sodium sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com