Contour control method for synchronous cross-coupling robot

A contour control and cross-coupling technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as the inability to apply industrial robot systems, achieve the effects of improving control effects, ensuring tracking accuracy, and reducing contour errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

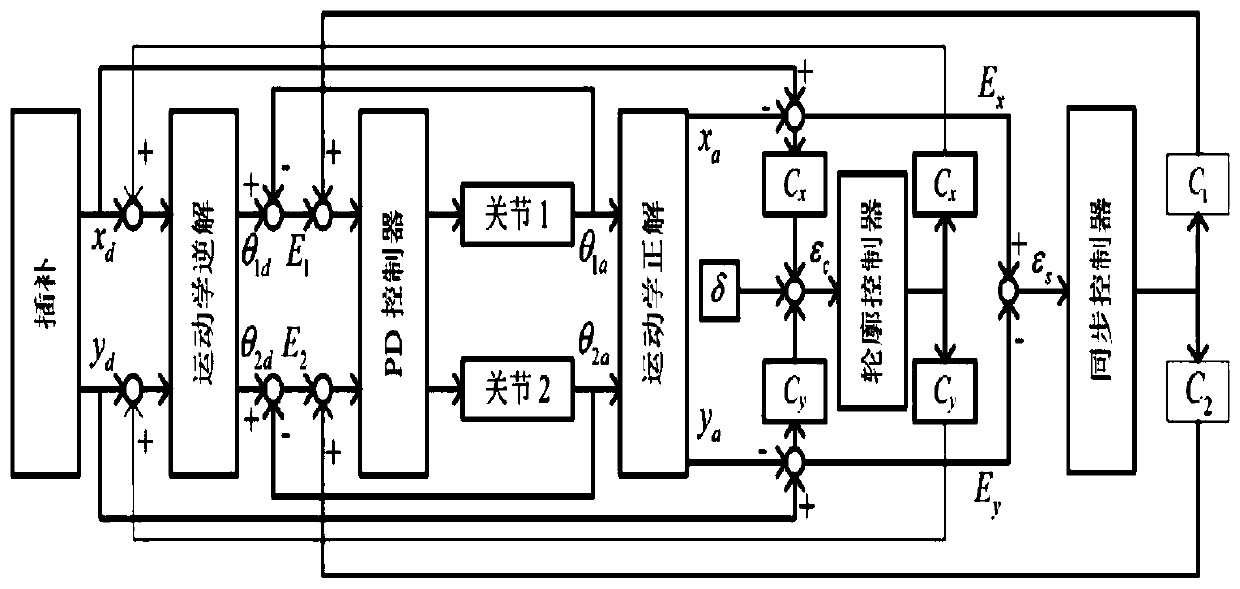

Method used

Image

Examples

Embodiment 1

[0095] The contour trajectory is elliptical, and the radius of the expected center contour trajectory is set to 8cm, the initial position of the end effector is (0.02, 0.35), and the setting of the initial position of the end ensures that the robot is always in the working space during the movement process. The specific trajectory The equation is:

[0096]

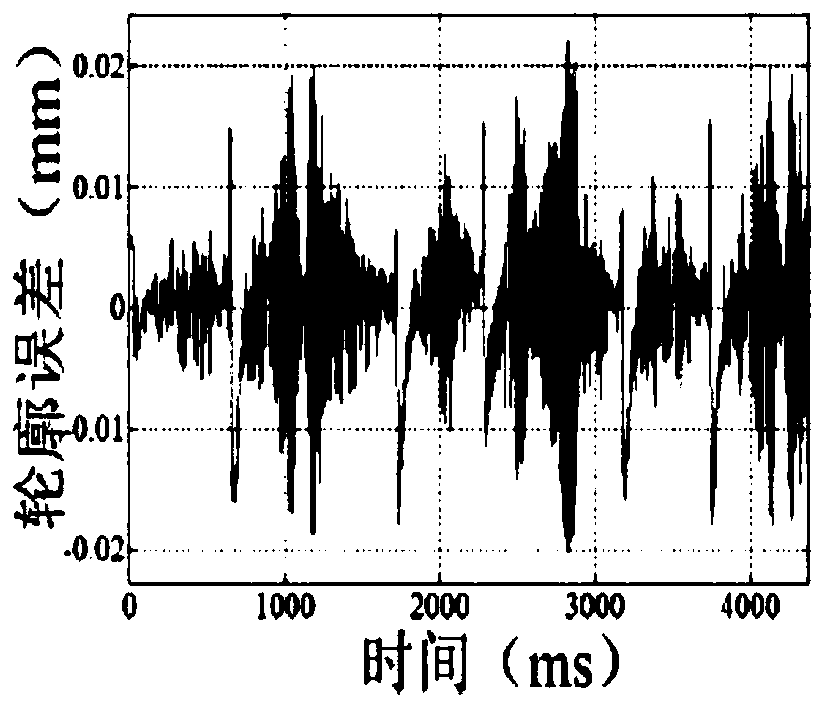

[0097]The angular velocity ω of the circular trajectory is set to low speed and medium speed to conduct experiments respectively. Firstly, the low speed state of ω=0.02rad / s is set, and the obtained motion contour error changes and experimental data are as follows: Figure 2a , Figure 2b , as shown in Table 2:

[0098] Table 2 Experimental data of low-speed circular trajectory

[0099]

[0100] The results of comparative experiments show that the contour error of synchronous cross-coupling control is significantly reduced, the maximum contour error is reduced by 3.12 μm, and the root mean square value is reduced b...

Embodiment 2

[0107] The contour trajectory is elliptical. Set the long radius of the expected circle center contour trajectory to 8cm, the short radius to 4cm, and the initial position of the end effector (0.02, 0.35), which effectively ensures the movement process of the system in the working space. The specific trajectory The equation is:

[0108]

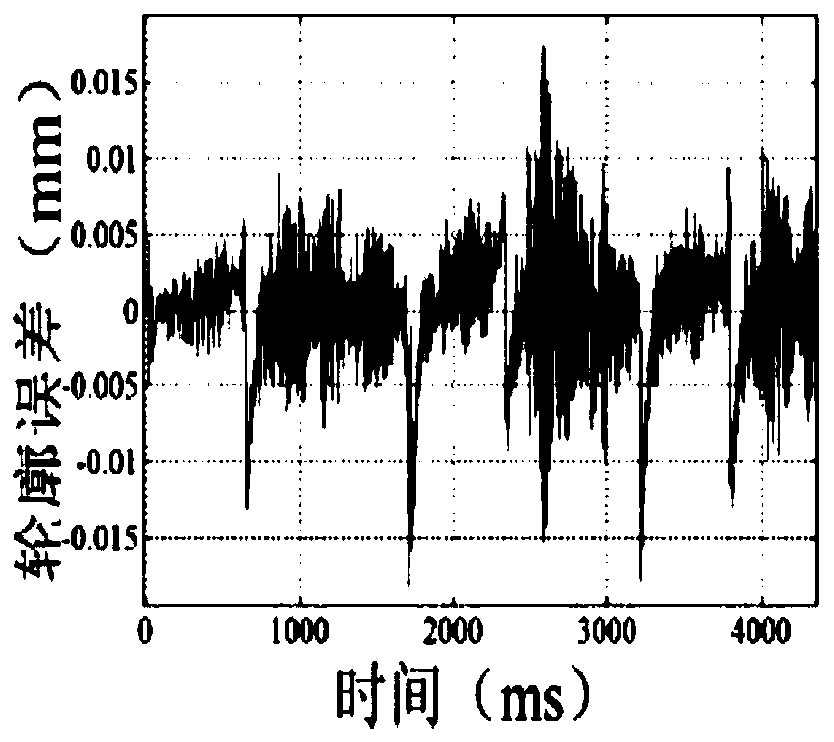

[0109] The motion contour error change and experimental data obtained by setting ω=0.02rad / s are as follows Figure 4a , Figure 4b And as shown in Table 4:

[0110] Table 4 Experimental data of low-speed elliptical trajectory

[0111]

[0112] Similarly, the comparison experiment results of the elliptical profile show that compared with the position loop cross-coupling control, the maximum error of the profile using the synchronous cross-coupling control is reduced by 6.21 μm, and the root mean square value is reduced by 1.11 μm.

[0113] It can be concluded that, for elliptical contours with more complex shapes, synchronous cross-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com