Rare earth aluminum-manganese alloy sterilization foil for fresh steaming brick of pet food package and production technology thereof

A technology of pet food and production process, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as crystallization and rolling difficulties, and achieve the effects of eliminating dendrite segregation, high flash point, and preventing blackening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

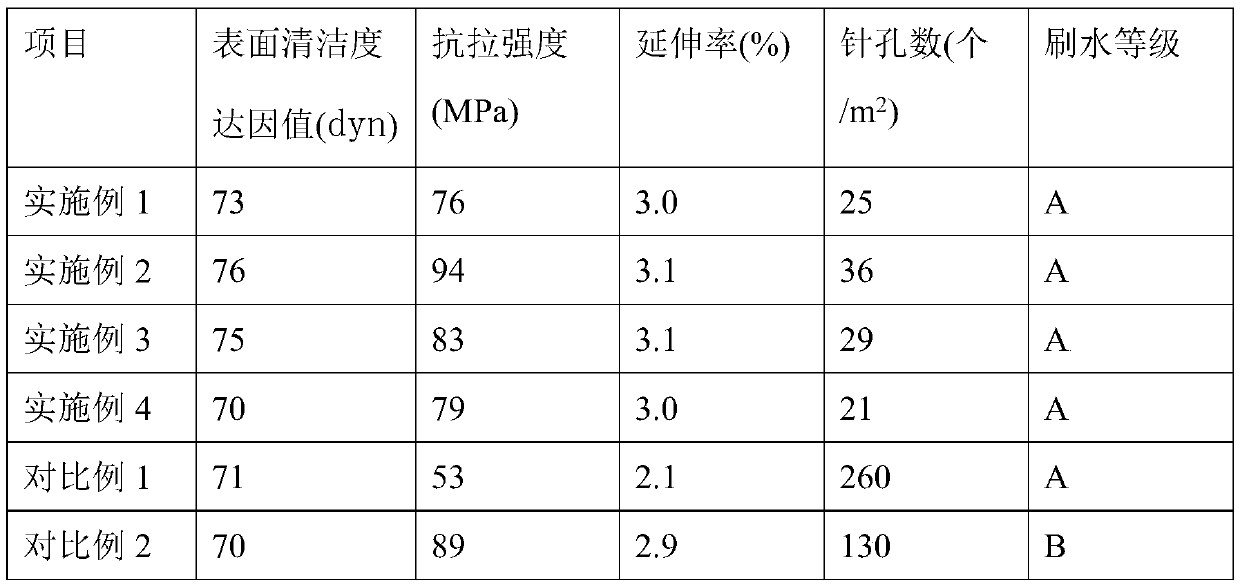

Examples

Embodiment 1

[0059] A rare earth aluminum-manganese alloy sterilizing foil for steaming fresh bricks for pet food packaging, including the following raw materials in mass percentage: Si: 0.18%, Fe: 0.40%, Cu: 0.13%, Mn: 1.15%, La: 0.13%, Mg: 0.005%, Zn: 0.01%, Ti: 0.01%, P: 0.0051%, Li: 0.018%, and the balance is Al.

[0060] A production process of rare earth aluminum-manganese alloy sterilizing foil for steaming fresh bricks for pet food packaging, comprising the following steps:

[0061] S1: Production of cast and rolled coils:

[0062]Furnace preparation→burden preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining)→degassing box degassing and slag removal→filter box Double-channel double-stage ceramic filter plate to filter and remove slag → cast and roll into 7.0mm continuous cast-rolled plate, and then wind up into cast-rolled coil; in the preparation of the furnace charge, t...

Embodiment 2

[0081] Rare earth aluminum-manganese alloy sterilizing foil for steaming fresh bricks for pet food packaging, including the following raw materials in mass percentage: Si: 0.22%, Fe: 0.47%, Cu: 0.15%, Mn: 1.22%, La: 0.17%, Mg: 0.008% , Zn: 0.02%, Ti: 0.03%, P: 0.008%, Li: 0.02%, and the balance is Al.

[0082] A production process of rare earth aluminum-manganese alloy sterilizing foil for steaming fresh bricks for pet food packaging, comprising the following steps:

[0083] S1: Production of cast and rolled coils:

[0084] Furnace preparation→burden preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining)→degassing box degassing and slag removal→filter box Double-channel double-stage ceramic filter plate to filter and remove slag → cast and roll into 7.0mm continuous cast-rolled plate, and then wind up into cast-rolled coil; in the preparation of the furnace charge, the...

Embodiment 3

[0103] A rare earth aluminum-manganese alloy sterilizing foil for steaming bricks for pet food packaging, including the following raw materials in mass percentage: Si: 0.26%, Fe: 0.55%, Cu: 0.17%, Mn: 1.35%, La: 0.21%, Mg: 0.01%, Zn: 0.03%, Ti: 0.01 to 0.05%, P: 0.01%, Li: 0.03%, and the balance is Al.

[0104] A production process of rare earth aluminum-manganese alloy sterilizing foil for steaming fresh bricks for pet food packaging, comprising the following steps:

[0105] S1: Production of cast and rolled coils:

[0106] Furnace preparation→burden preparation→furnace loading→melting→stirring and slag removal→composition adjustment→in-furnace treatment (first refining)→converter and standing (second refining)→degassing box degassing and slag removal→filter box Double-channel double-stage ceramic filter plate to filter and remove slag → cast and roll into 7.0mm continuous cast-rolled plate, and then wind up into cast-rolled coil; in the preparation of the furnace charge, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com