Airbag type constant-pressure tension platform

An airbag-type tension technology, applied in the field of steel rolling machinery, can solve the problems of inaccurate tension adjustment, inconsistent pressing force of the strip, uneven pressure, etc., and achieve simple tension adjustment and control, compensate for tension fluctuations, and uniform pressing force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

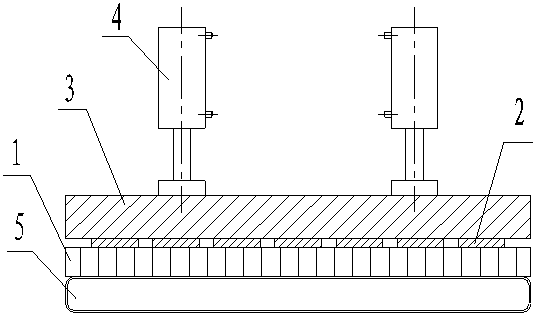

[0014] Further describe below in conjunction with accompanying drawing:

[0015] Such as figure 1 As shown, the airbag type constant pressure tension table is mainly composed of the upper pressing plate 3, the lower pressing plate 1 and the pressing oil cylinder 4. The pressing oil cylinder 4 applies pressure to the upper pressing plate 3, and the multiple strips between the upper pressing plate 3 and the lower pressing plate 1 The strip 2 is compressed so that the strip 2 builds up tension during the crimping process, which is: a rubber air bag 5 is arranged under the lower pressing plate 1, and the lower pressing plate 1 is a piano-key structure in which multiple pieces are arranged side by side.

[0016] When working, first pass the strip 2 through the lower platen 1 and the upper platen 3, let the pressure cylinder 4 press down, give the lower platen 1 and the platen 2 a large pressing force F1, and the air bag 5 passes through the pressure reducing valve group It is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com