A sand and gravel separator

A technology for a sand and gravel separator and a shell, which is applied in the field of sand and gravel separators, can solve the problems of high viscosity of slurry and water, low separation rate, and insufficient water separation, so as to improve porosity, water permeability, and sand water. The effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

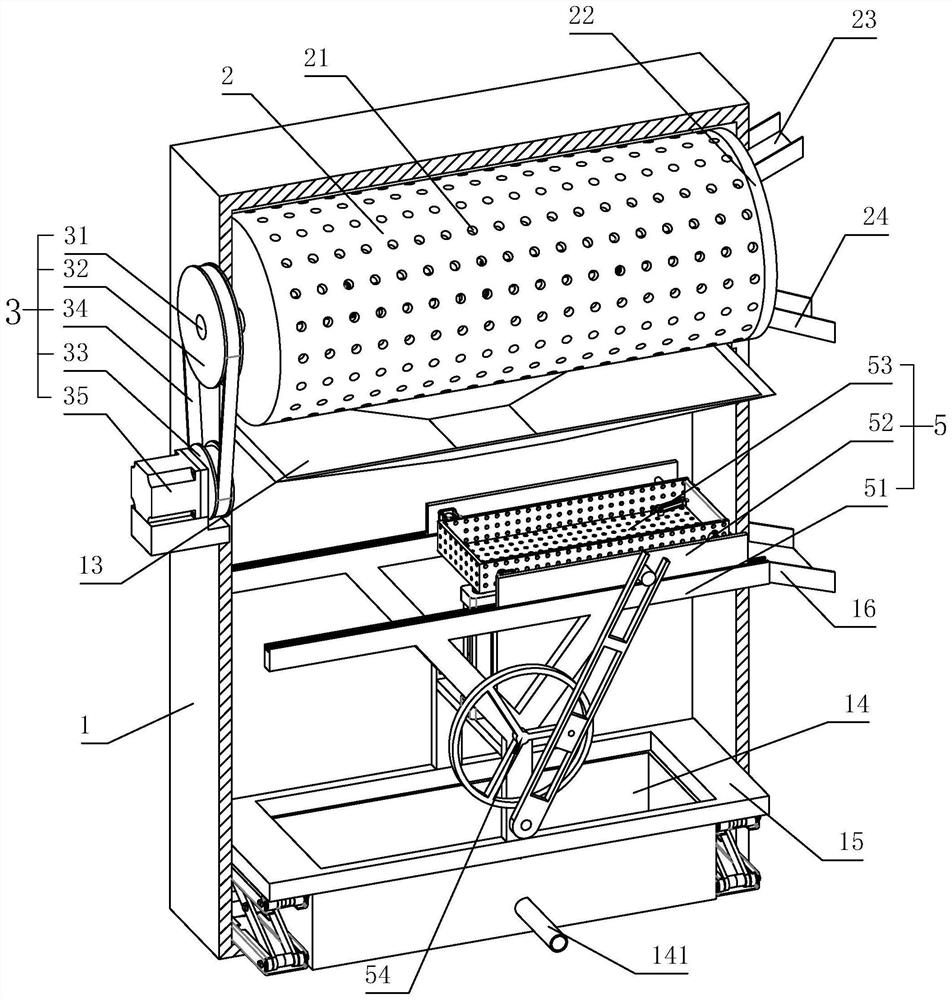

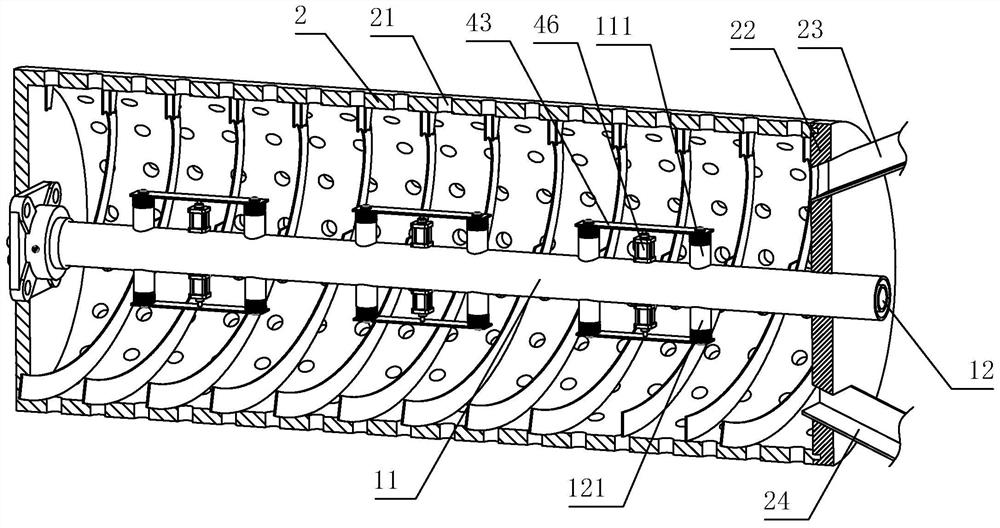

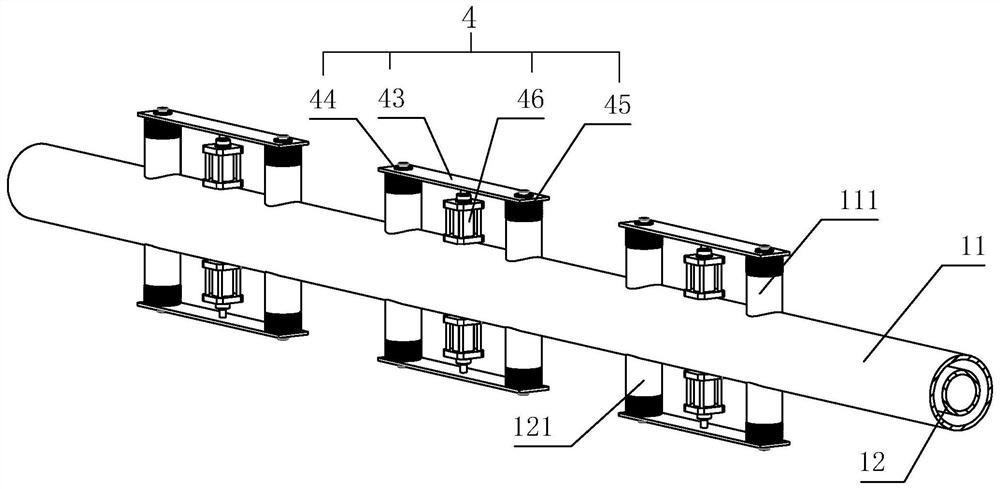

[0039] refer to figure 1 , is a kind of sand and gravel separator disclosed by the present invention, which includes a shell 1, a drum 2 which is rotatably connected to the shell 1 around its own axis and has an opening at one end, a first drive assembly 3 for driving the drum 2 to rotate, and a fixed connection The sealing plate 22 is connected to the casing 1 and rotatably connected to the end of the drum 2 with an opening. The sealing plate 22 is provided with a feed hopper 23 and a stone discharge hopper 24 located below the feed hopper 23, the side wall of the drum 2 is provided with a first sieve hole 21 for sand to pass through, and the inner wall of the drum 2 is provided with a screw pusher. leaves (not shown).

[0040] refer to figure 1 , figure 2 The first drive assembly 3 includes a rotating shaft 31 coaxially fixedly connected to the end fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com