A semiconductor surface insulating film processing device

A technology for processing device and insulating film, applied in spraying device and other directions, can solve problems such as affecting appearance quality, wasting materials, affecting efficacy, etc., and achieves the effect of improving appearance quality and beauty, improving spraying efficiency, and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

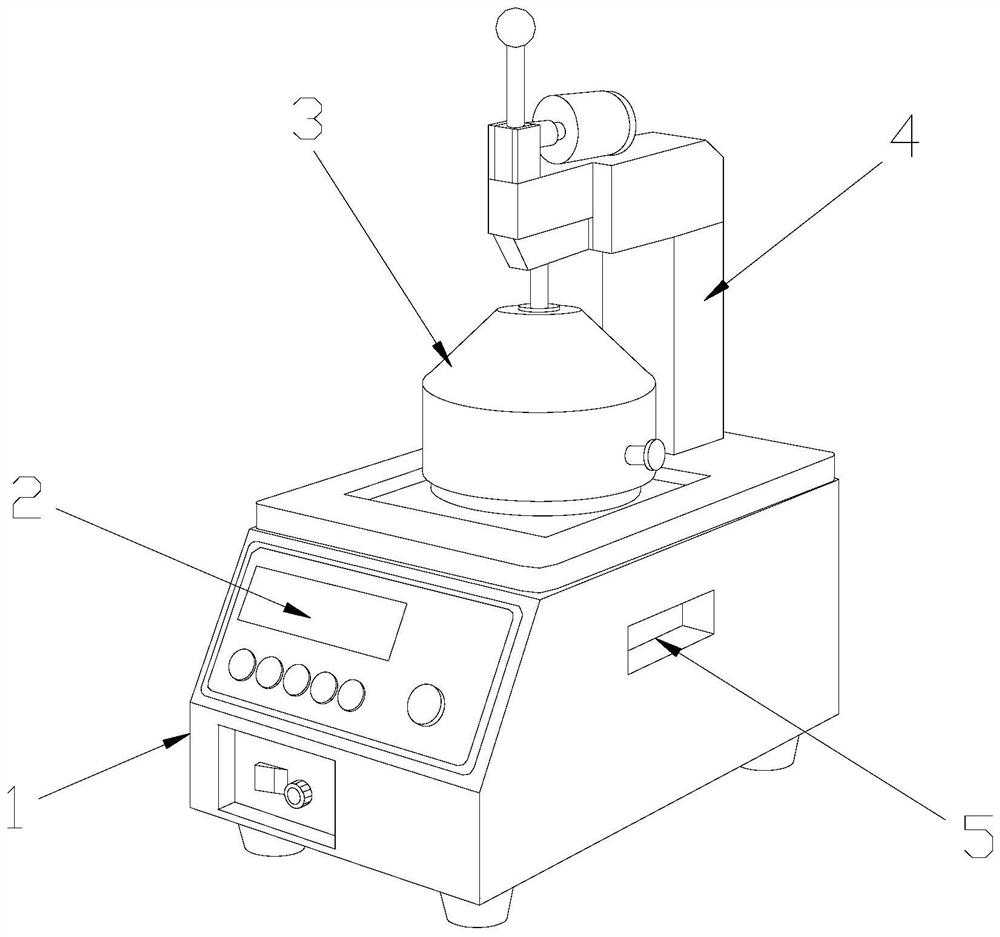

[0029] see Figure 1-Figure 3 , the present invention provides a semiconductor surface insulating film processing device, its structure includes a film spraying processing machine 1, an operation panel 2, a spraying sealing device 3, a spraying machine head 4, and a lifting groove 5, and the front end surface of the film spraying processing machine 1 is An operation panel 2 is installed on the top of the film spraying processing machine 1. A spraying machine head 4 is arranged on the top of the film spraying processing machine 1. The film spraying processing machine 1 is connected with the spraying machine head 4. The left and right sides of the film spraying processing machine 1 Lifting grooves 5 are provided on the sides, and a spraying sealing device 3 is provided at the middle position of the top of the film spraying processing machine 1, and the film spraying processing machine 1 and the spraying sealing device 3 are movably connected;

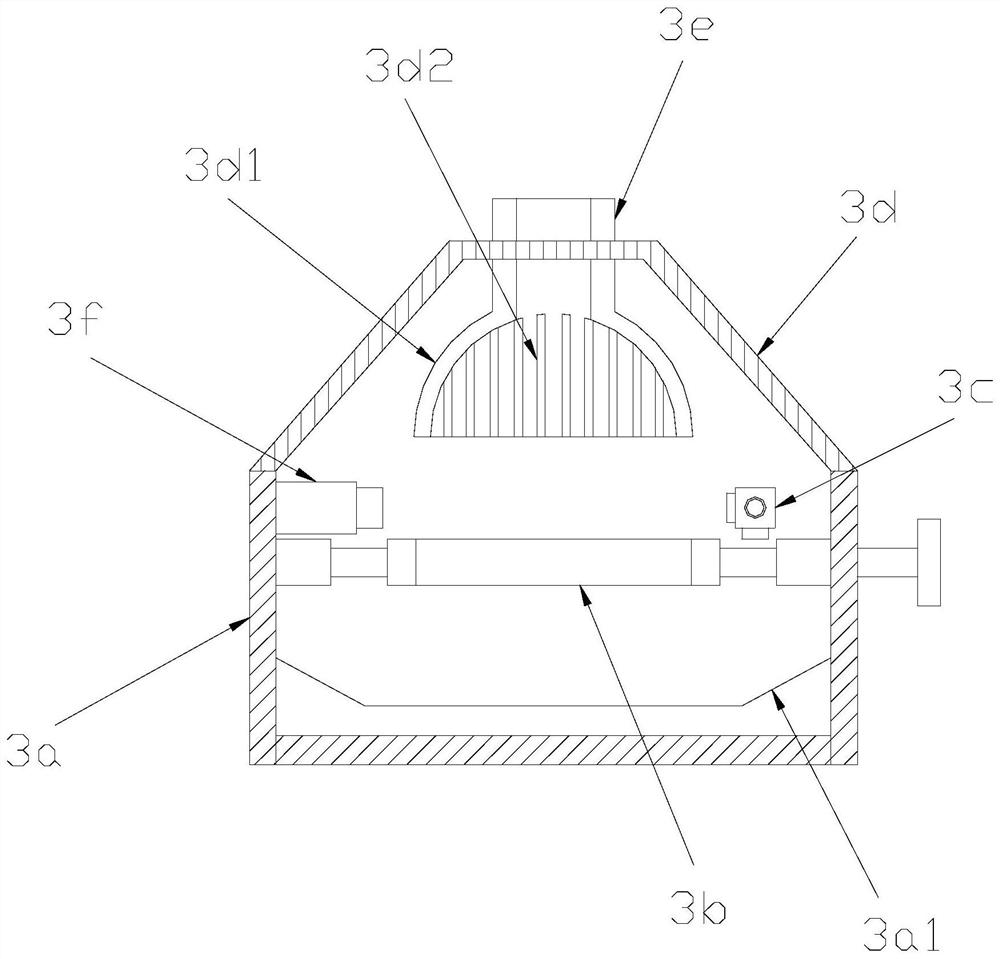

[0030] The spray sealing device 3 ...

Embodiment 2

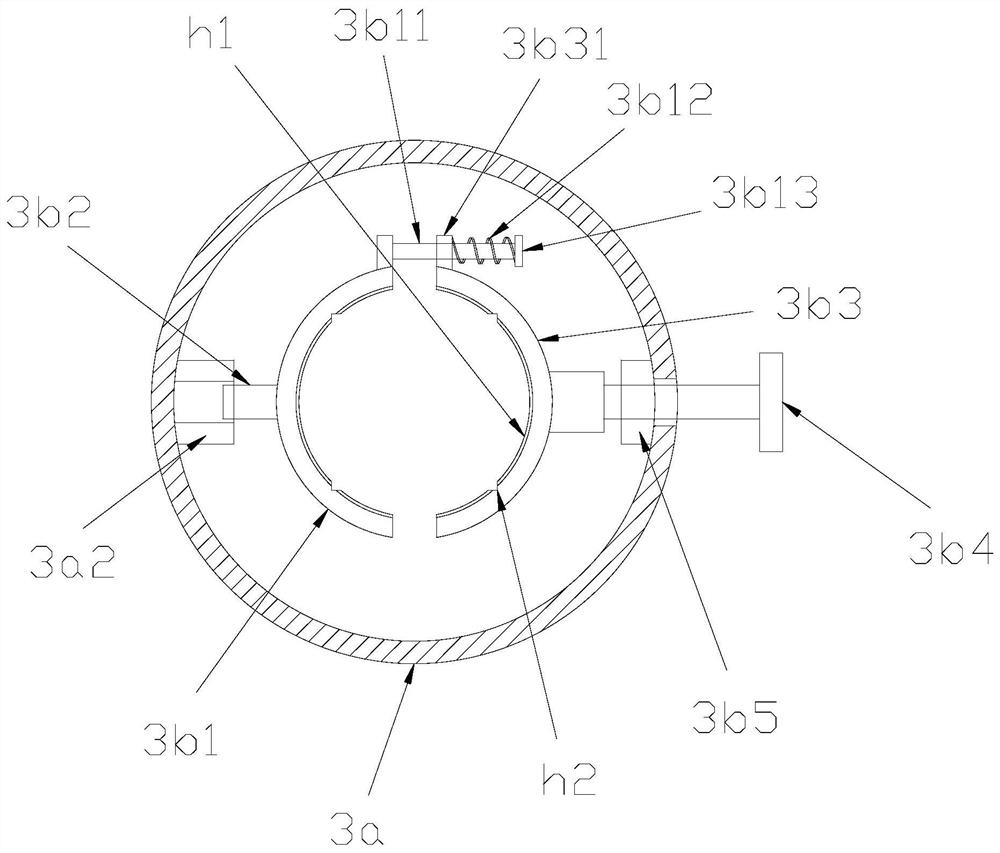

[0038] see Figure 1-Figure 5 , the present invention provides a semiconductor surface insulating film processing device, the scraping mechanism 3c is composed of a bracket 3c1, a telescopic rod 3c2, a sliding column 3c3, a storage groove 3c4, and a soft scraping strip 3c5, and the bracket 3c1 is about Both ends are provided with storage grooves 3c4 on the inner sides, and said storage grooves 3c4 are provided with telescopic rods 3c2. The column 3c3, the telescopic rod 3c2 and the sliding column 3c3 are fixedly connected, the bottom of the bracket 3c1 is provided with a soft scraping strip 3c5, and the bracket 3c1 is glued to the soft scraping strip 3c5.

[0039] The front end of the bracket 3c1 is provided with an armature 3c11, the bracket 3c1 is fixedly connected with the armature 3c11, and the rear end of the bracket 3c1 is equipped with a tension spring 3c12.

[0040] A spraying guide cover 3d1 is provided under the inner bottom end of the dustproof cover body 3d, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com