Construction method of expanded-head prestressed concrete anchor rod

A bolt construction and prestressing technology, which is applied in the direction of foundation structure engineering, sheet pile walls, protective devices, etc., can solve problems that do not involve construction methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

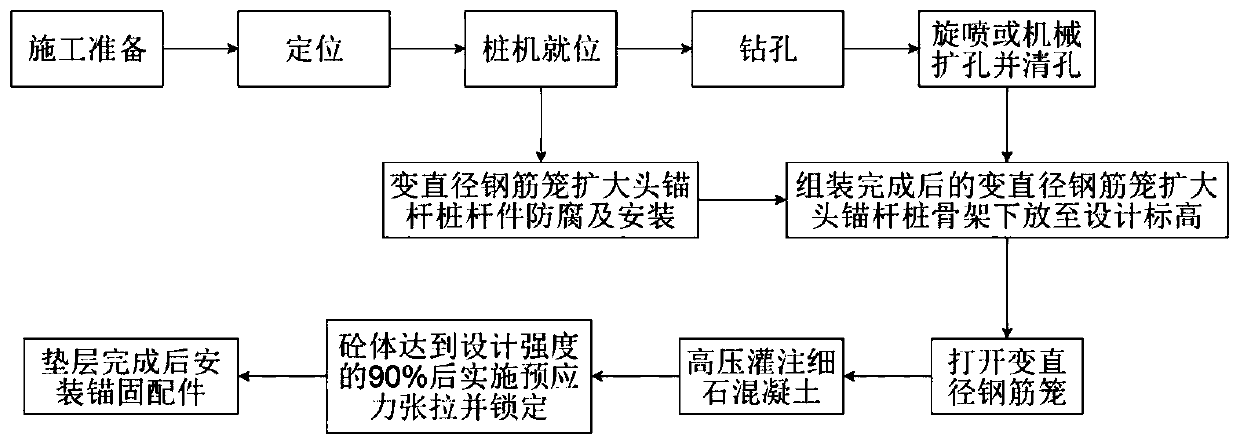

Method used

Image

Examples

Embodiment Construction

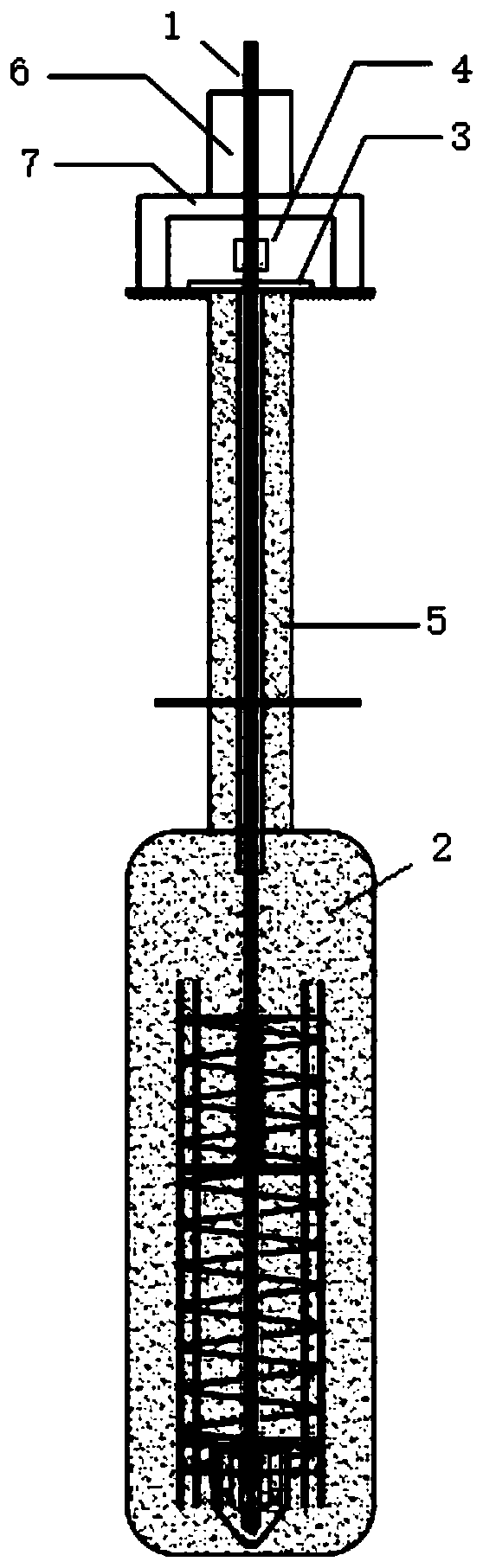

[0062] Such as Figure 2-3 Shown: steel bar clamp (the simplest way is composed of fixed nut 8, force clamp 9, inner penetrating oil cylinder 6 and fixed nut 8), steel bar (main bar) 1, expanding head 2, bracket plate 3, lock nut 4. Anchor rod casting body 5, inner penetrating oil cylinder 6, bracket 7, fixing nut 8, force clamp 9, force applying machine 10. The support plate 3 is placed on the reinforced soil. The pipe sleeve 14 can be an outer coat of an unbonded steel bar oiled layer, a mesh steel bar 15 . Pile end prestressed anchor plate (anchor bracket backing plate) 3. Apply prestressed pile end elevation 21. Free (ordinary) section bore hole diameter 16, pouring port 17, connection point 18 of mesh reinforcement 15 and pile end prestressed anchor plate (support backing plate) 3. Stress Gauge11. The bracket plate 3 is placed on the reinforced soil body 12, and the surfaces of various locking brackets 3-1 are provided with steel bar perforations.

[0063] Figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com