Ductile cast iron spiral pile

A ductile iron and screw pile technology, applied in the field of screw piles, can solve the problems of irregular shape of the rotor, difficult transportation, large space occupation, etc., and achieve the effects of reducing transportation costs, improving transportation efficiency, and avoiding cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

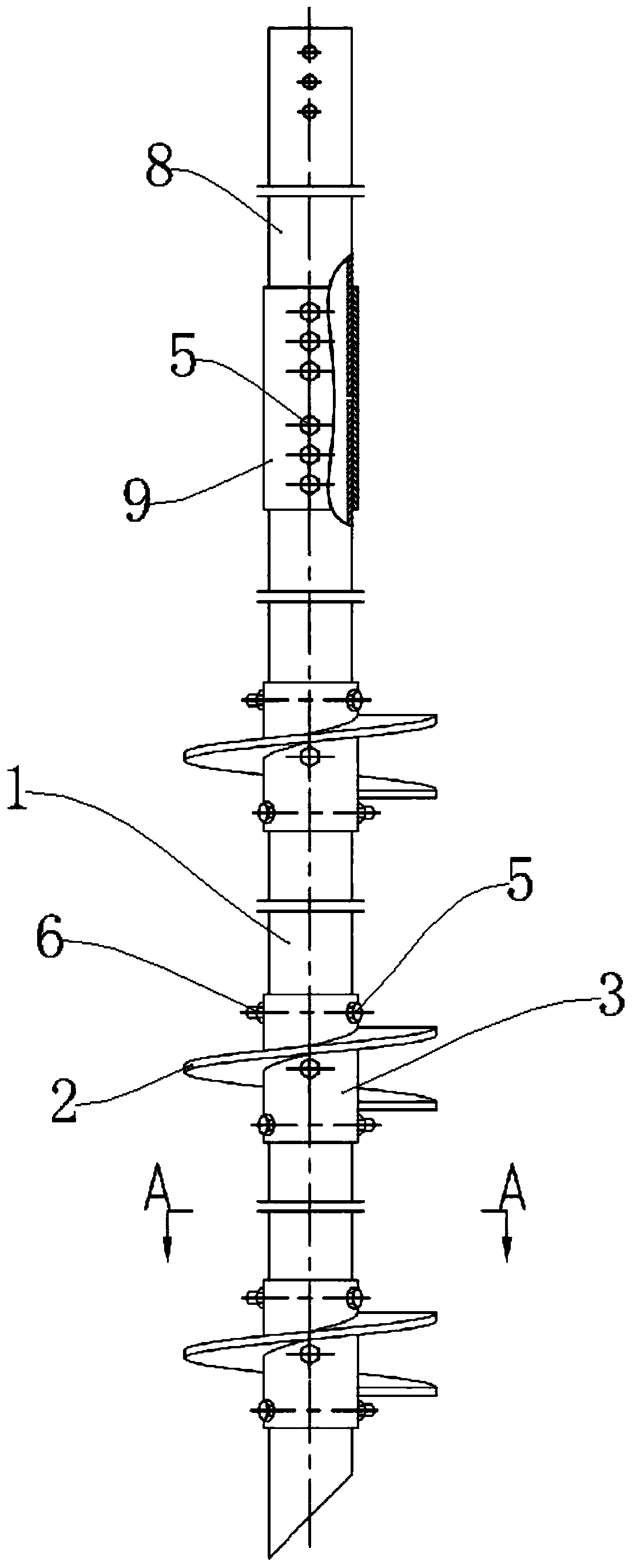

[0029] Such as Figure 1-Figure 5 As shown, a nodular cast iron screw pile includes a guide tube 1, a rotor 2, a rotor sleeve 3, an extension tube 8 and a connecting sleeve. Both the guide pipe 1 and the extension pipe 8 are made of ductile iron, and the rotor 2, the rotor sleeve 3 and the connecting sleeve are made of Q345 steel.

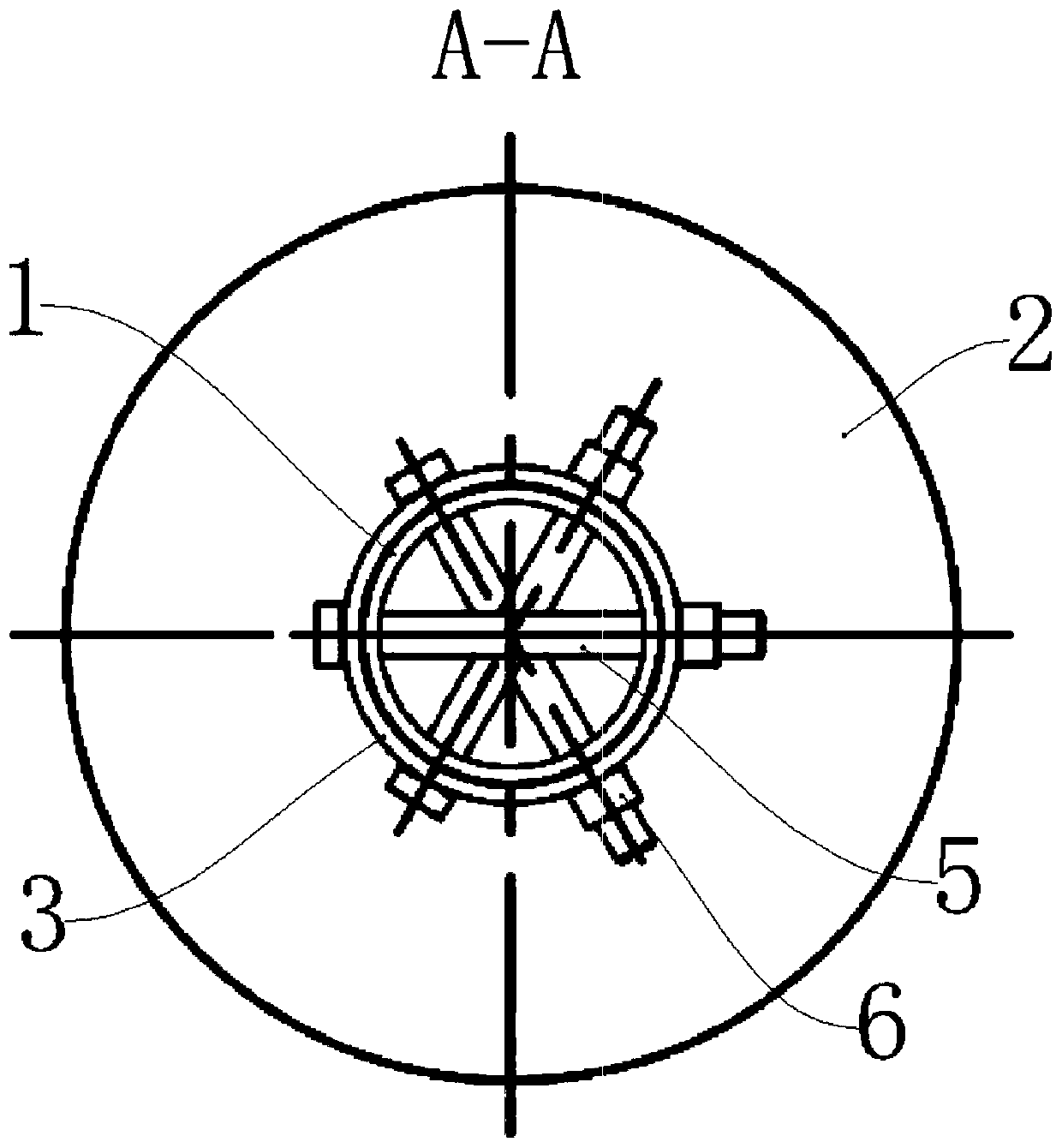

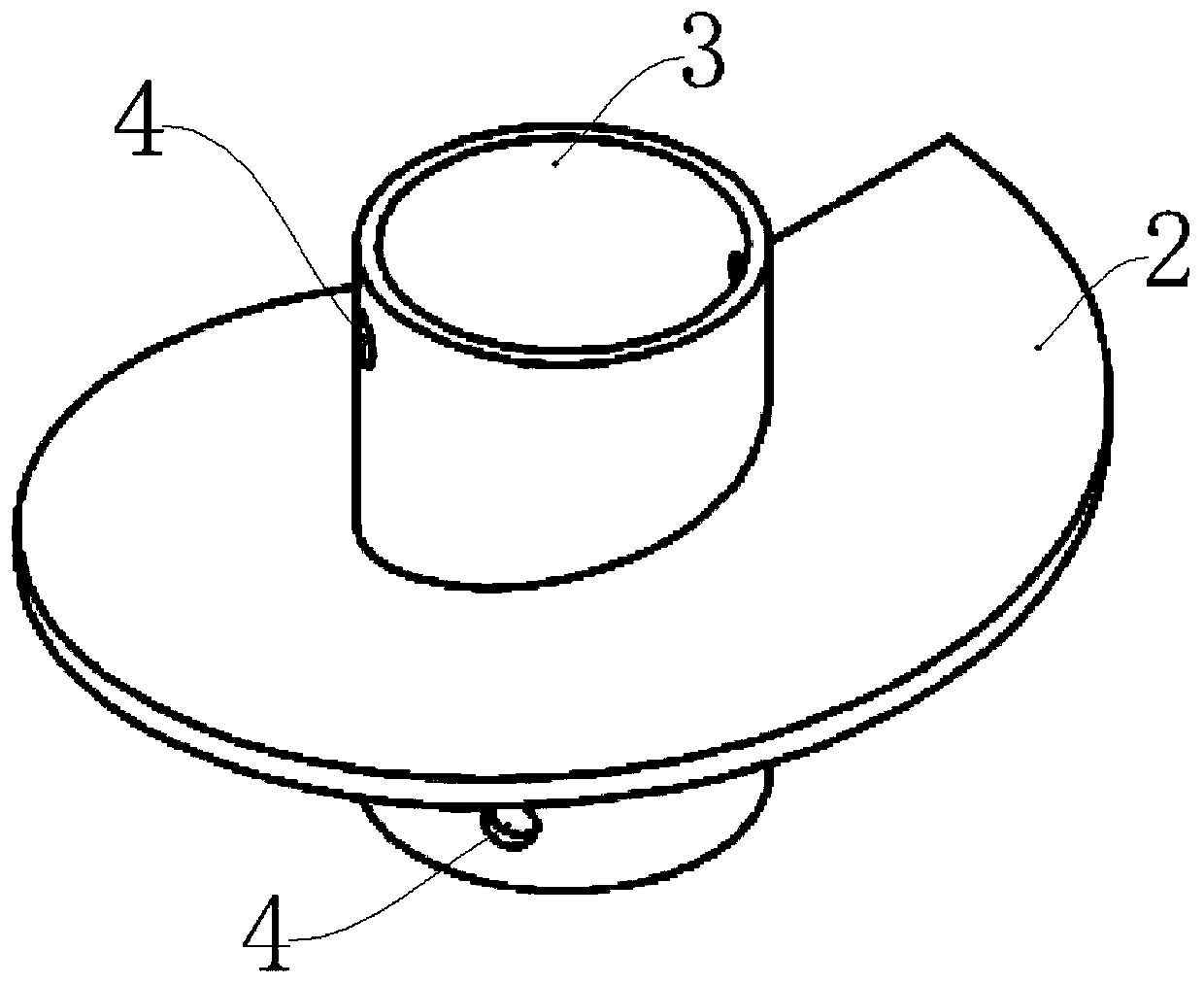

[0030] The rotor 2 is in a spiral shape, and the rotor 2 is welded to the rotor sleeve 3 , and each rotor sleeve 3 is provided with a rotor 2 . The rotor sleeve 3 is socketed with the guide pipe 1 and fixedly connected through a threaded connector, specifically, as Figure 3-Figure 5 As shown, the rotor sleeve 3 and the guide tube 1 are respectively provided with three connecting holes 4 matching the threaded connectors. The axis of the connecting holes 4 is horizontal and intersects the axis of the guide tube 1. Any two connecting holes The axes of 4 are not coplanar. In the first embodiment, the rotor sleeve 3 is fixedly connected with the gui...

Embodiment 2

[0045] Such as Figure 6 As shown, a nodular cast iron screw pile includes a guide tube 1, a rotor 2, a rotor sleeve 3, an extension tube 8 and a connecting sleeve. The guide tube 1, rotor 2, rotor sleeve 3, extension tube 8 and connecting sleeve are all made of ductile iron, so the manufacturing cost of the screw pile in this embodiment is relatively low.

[0046] The rotor 2 is helical, and the rotor 2 and the rotor sleeve 3 are integrally cast. Each rotor sleeve 3 is provided with a rotor 2 . The rotor sleeve 3 is socketed with the guide pipe 1 and fixedly connected through a threaded connector, specifically, as Figure 6 As shown, the rotor sleeve 3 and the guide tube 1 are respectively provided with three connecting holes 4 matching the threaded connectors. The axis of the connecting holes 4 is horizontal and intersects the axis of the guide tube 1. Any two connecting holes The axes of 4 are not coplanar. In the second embodiment, the rotor casing 3 and the guide pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com