Assembled capping beam construction safety protection integrated platform

A safety protection and construction platform technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as insufficient load-bearing capacity and impact on construction period, and achieve the effect of improving static friction, load-bearing capacity and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

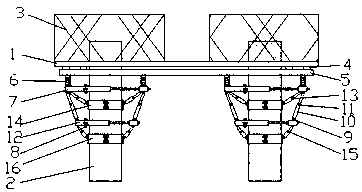

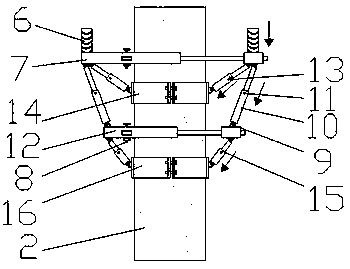

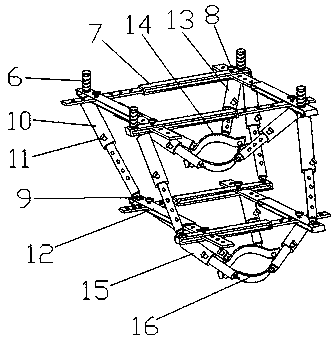

[0028] Reference Figure 1-4 , A prefabricated cover beam construction safety protection integrated platform, including a construction platform body 1, which is erected on two sets of bridge piers 2, a guardrail 3 is arranged around the top surface of the construction platform body 1, and a bottom surface of the construction platform body 1. There are four longitudinal channels 4 symmetrically, of which two longitudinal channels 4 are located on the left side of the left pier 2, the other two longitudinal channels 4 are located on the right side of the right pier 2, and four longitudinal channels 4 Two symmetrical transverse channel steels 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com