Conductive carbon paper and preparation method thereof

A conductive carbon and conductive technology, applied in the field of conductive carbon paper and its preparation, can solve the problems of poor catalyst layer bonding and rough surface of carbon paper, etc., and achieve high air distribution, high conductivity, and high gas diffusivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

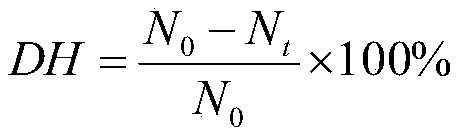

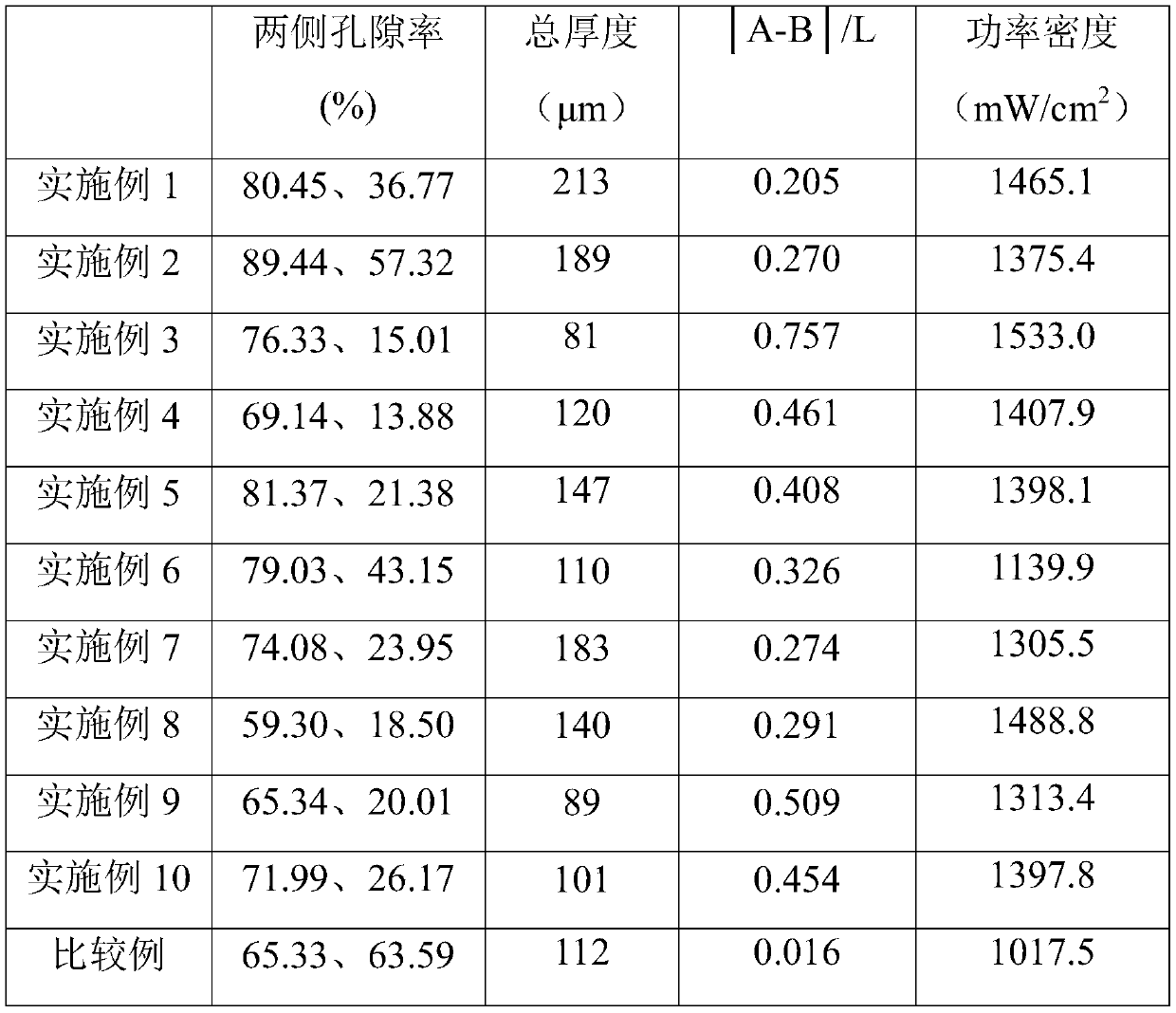

[0032] A conductive carbon paper, the conductive carbon paper is composed of 2-10 layers of single-layer carbon fiber paper with a porosity of 10-80%, wherein the porosity of the single-layer carbon fiber paper on the outermost side is denoted as A, and the other side is The porosity of the outermost single-layer carbon fiber paper is recorded as B, where the units of A and B are %, and the total thickness of the conductive carbon paper is recorded as L, where the unit of L is μm. The three must meet the following relationship: 0.2≤│A-B │ / L≤0.8.

[0033] The conductive carbon paper is an asymmetric porous structure carbon paper, the side of the conductive carbon paper with high porosity is used to contact the bipolar plate, and the side with low porosity is used to contact the catalyst layer and has a microporous layer. The carbon papers are arranged in order of porosity from small to large or from large to small.

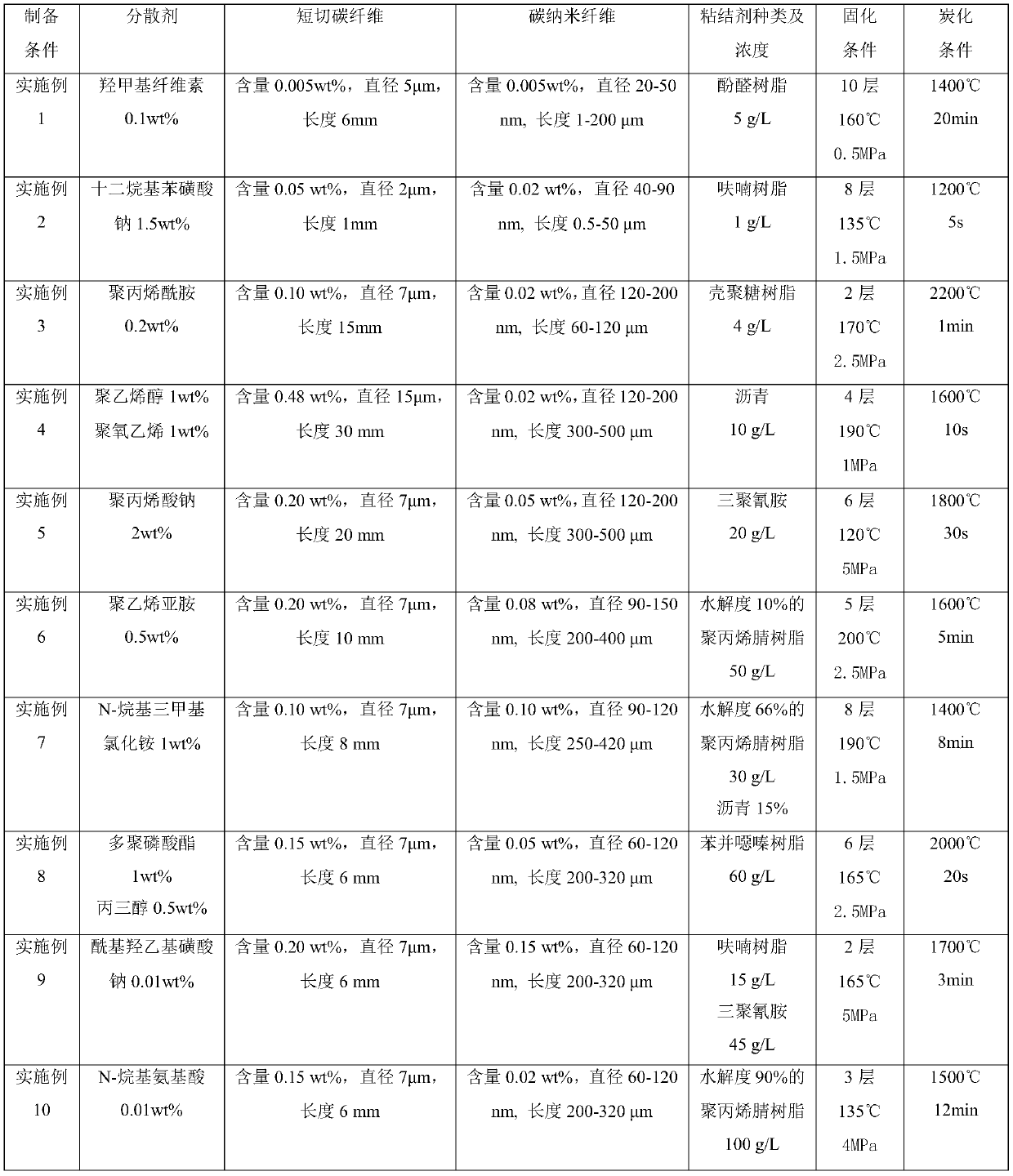

[0034] A preparation method of conductive carbon paper, com...

Embodiment 2~10

[0041] A conductive carbon paper, the conductive carbon paper is composed of 2-10 layers of single-layer carbon fiber paper with a porosity of 10-80%, wherein the porosity of the single-layer carbon fiber paper on the outermost side is denoted as A, and the other side is The porosity of the outermost single-layer carbon fiber paper is recorded as B, where the units of A and B are %, and the total thickness of the conductive carbon paper is recorded as L, where the unit of L is μm. The three must meet the following relationship: 0.2≤│A-B │ / L≤0.8.

[0042] The conductive carbon paper is an asymmetric porous structure carbon paper, the side of the conductive carbon paper with high porosity is used to contact the bipolar plate, and the side with low porosity is used to contact the catalyst layer and has a microporous layer. The carbon papers are arranged in order of porosity from small to large or from large to small.

[0043] A preparation method of conductive carbon paper, cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com