Cleaning and drying device for woollen sweater processing

A drying device and technology for sweaters, applied in the field of sweaters, can solve the problems of low cleanliness, shrinkage and deformation of sweaters, high labor intensity of workers, etc., so as to achieve high work efficiency, reduce fatigue, improve Effect of drying efficiency and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

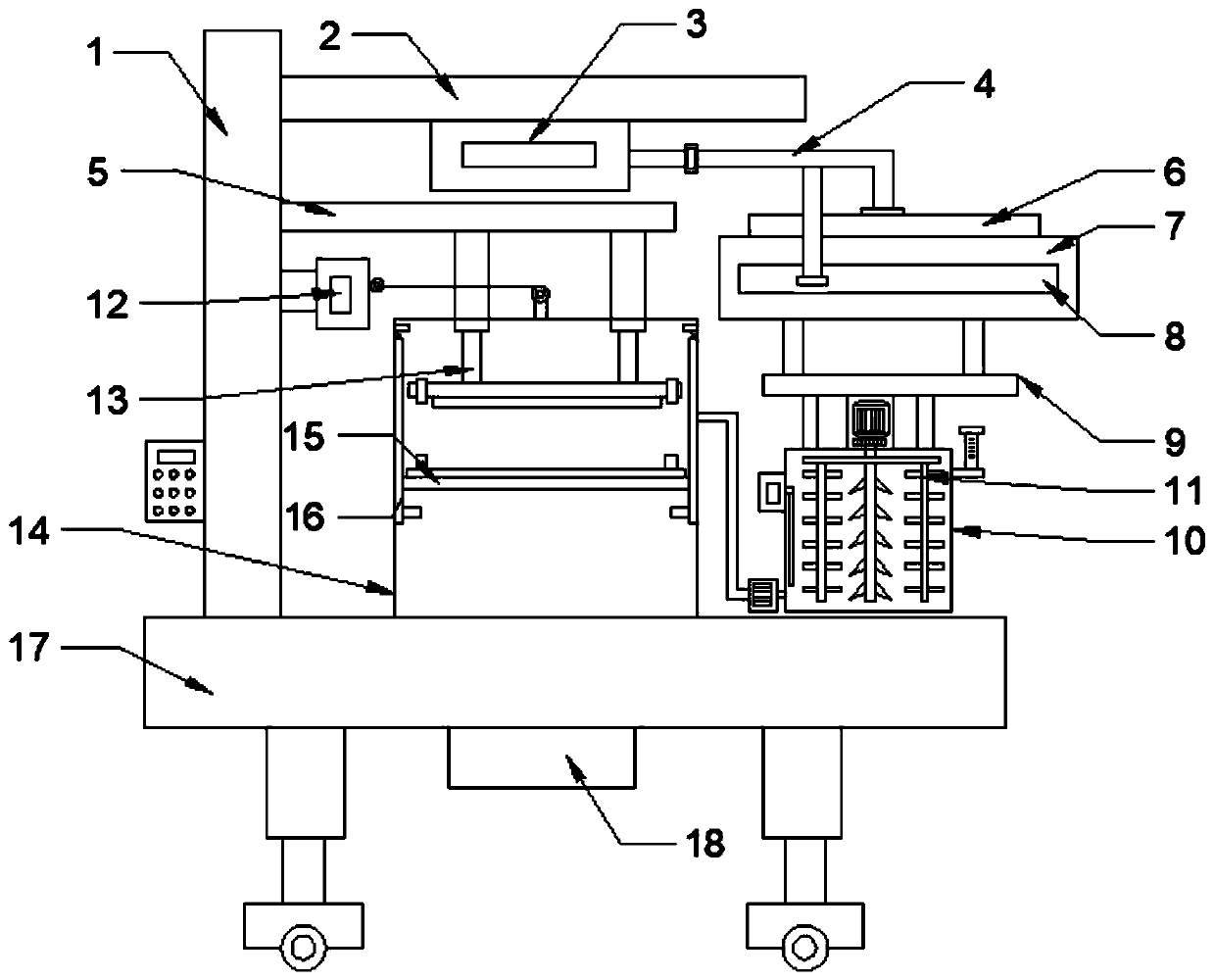

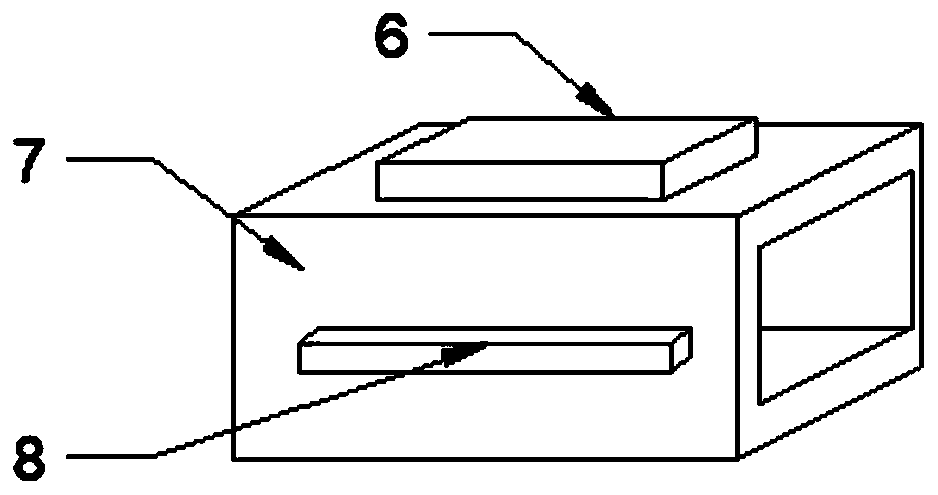

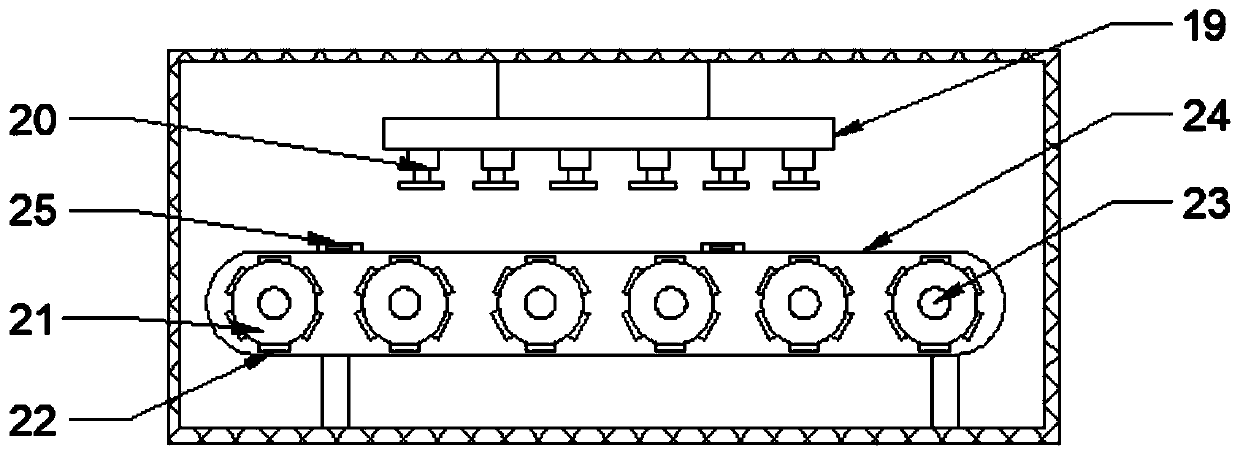

[0022] see Figure 1~3 , in an embodiment of the present invention, a washing and drying device for woolen sweater processing includes a mounting frame 1; the mounting frame 1 is mounted on the top of a base 17; Box 10; the liquid medicine mixing box 10 is connected to the cleaning box 14 through a water pipe; the water pipe is provided with a solenoid valve and a pressure pump; the inside of the cleaning box 14 is provided with a placement mechanism 15; the inside of the cleaning box 14 corresponds to a placement mechanism 15 is provided with limit slide rail 16; The bottom end of described limit slide rail 16 is equipped with limit block; One side corresponding placement mechanism 15 of described installation frame 1 is provided with vibrating mechanism 12 and squeezing cleaning mechanism 13; The liquid mixing box 10 is provided with a stirring mechanism 11 and a heater; the top of the liquid medicine mixing box 10 is connected to the bottom of the drying box 7 through a fix...

Embodiment 2

[0030] see figure 1 , the bottom of the base 17 is equipped with a moving mechanism; the moving mechanism includes a hydraulic telescopic rod; the hydraulic telescopic rod is provided with at least four; the bottom of the hydraulic telescopic rod is equipped with a lifting box; the lifting box There is a lifting mechanism inside; the bottom end of the lifting mechanism is connected with a moving wheel; through the setting of the lifting mechanism, the moving wheel can be put into the inside of the lifting box; through the setting of the hydraulic telescopic rod, the height of the device can be adjusted, which is convenient for workers to operate , Reduce the fatigue of workers, suitable for workers of different heights.

[0031] The working principle of the present invention is: add washing medicine through the medicine feeding pipe, fully mix the medicine and water through the setting of the stirring mechanism 11; heat through the heater, and the No. 1 temperature sensor sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com