Movable grabbing mechanism for towel cloth

A technology of grabbing mechanism and terry cloth, which is applied in the direction of winding strips, sending objects, thin material processing, etc., and can solve the problems of bloated structure and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

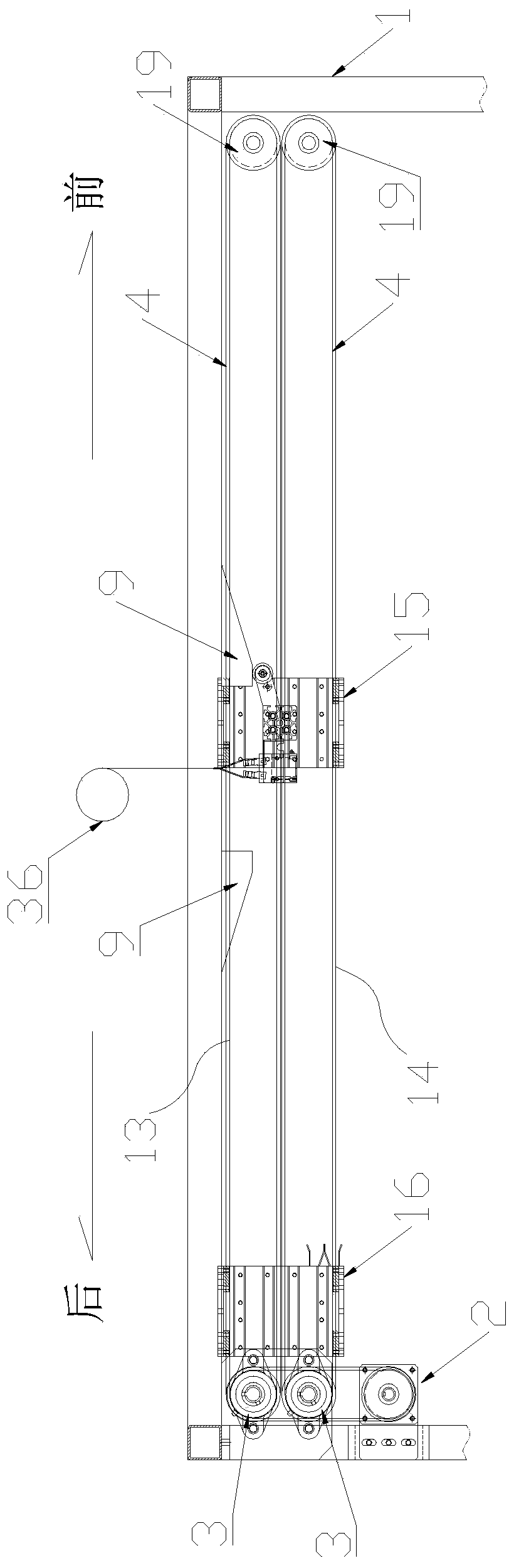

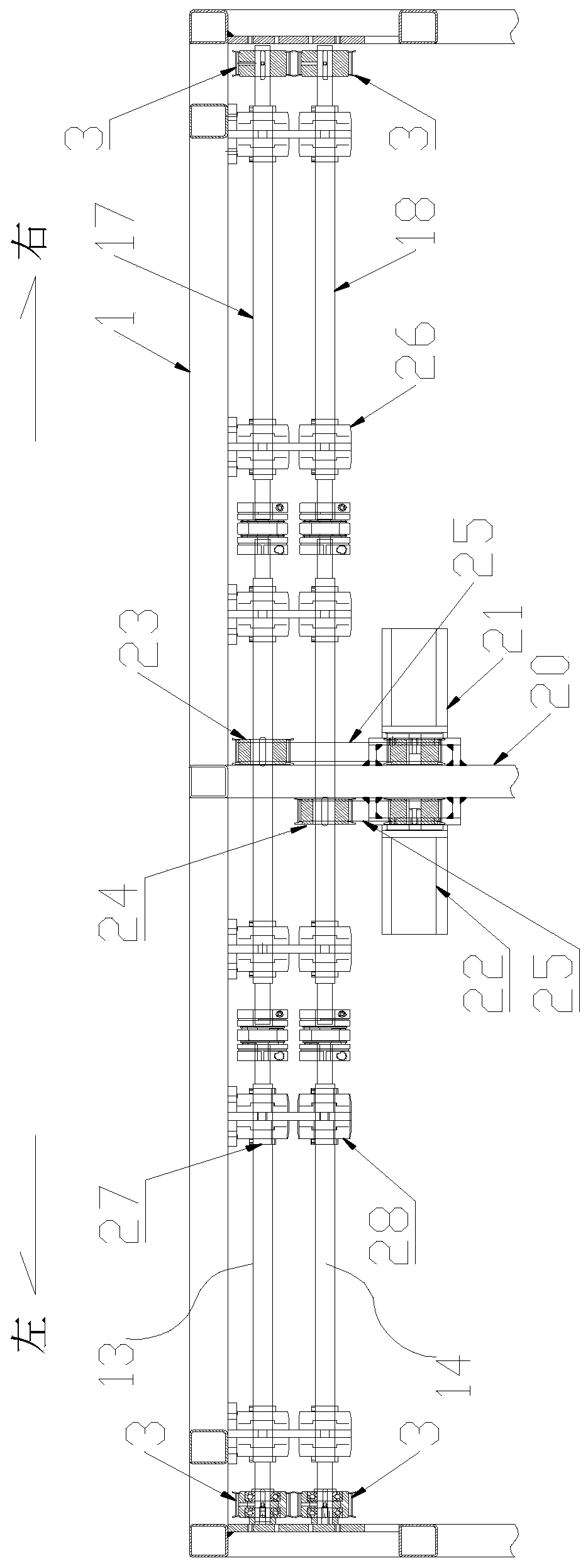

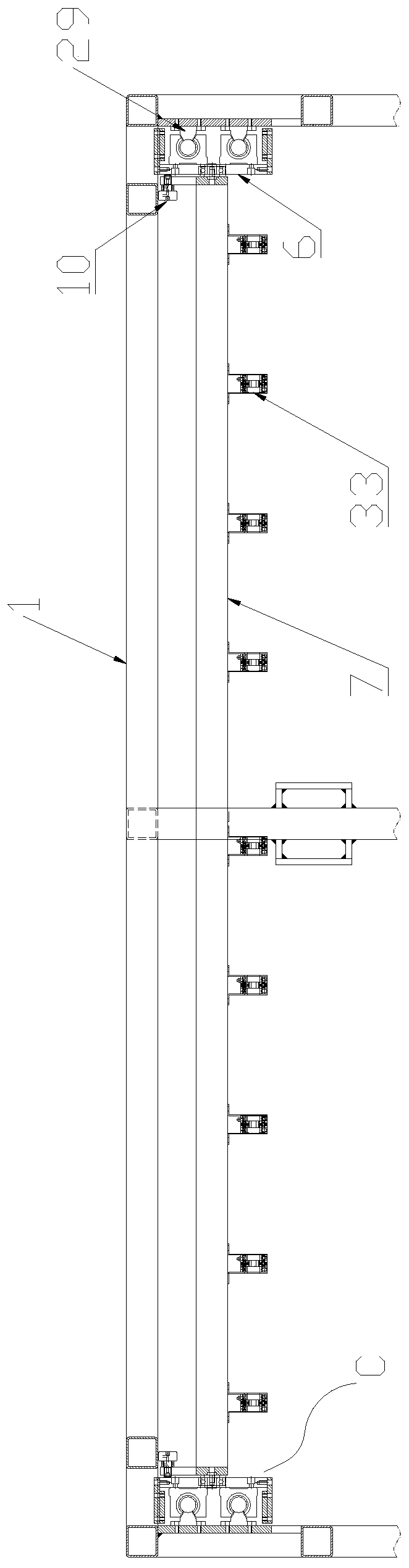

[0030] Such as Figure 1 to Figure 3 As shown, a mobile grabbing mechanism for terry cloth includes a frame 1, a driving assembly and a grabbing assembly.

[0031] The driving assembly is used to move the grabbing assembly, and the driving assembly includes a driving motor 2 , a synchronous wheel 3 , a driven wheel 19 and a synchronous belt 4 . Such as figure 1 As shown, the synchronous belt 4 is tensioned on the synchronous wheel 3 and the driven wheel 19 along the front and rear direction of the frame 1, and the drive motor 2 indirectly drives the synchronous wheel 3 to rotate through the transmission shaft, thereby driving the synchronous belt 4 to reciprocate.

[0032] Gripper assembly for gripping and pulling flat terry cloth, e.g. figure 1 , Figure 3 to Figure 5 As shown, the grab assembly includes a connecting plate 6 , a beam 7 , a jaw 8 , a follower boss 9 and a follower 19 . The connecting plate 6 is fixedly installed on the synchronous belt 4, and the synchrono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com