Safe and reliable glass hot fix stone grinding equipment

A reliable and glass technology, applied in the field of glass hot drilling and grinding equipment, can solve problems such as hidden dangers, affecting grinding efficiency, small size of glass hot drilling, etc., to achieve the effect of improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

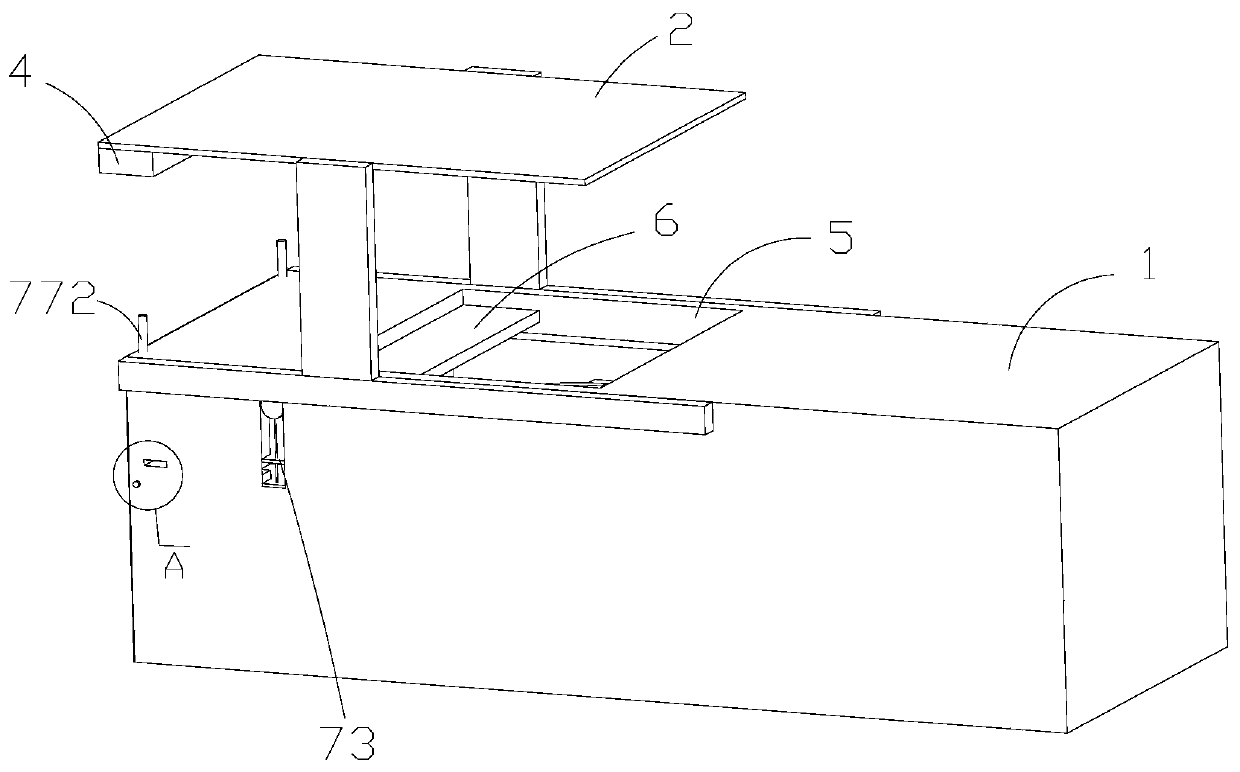

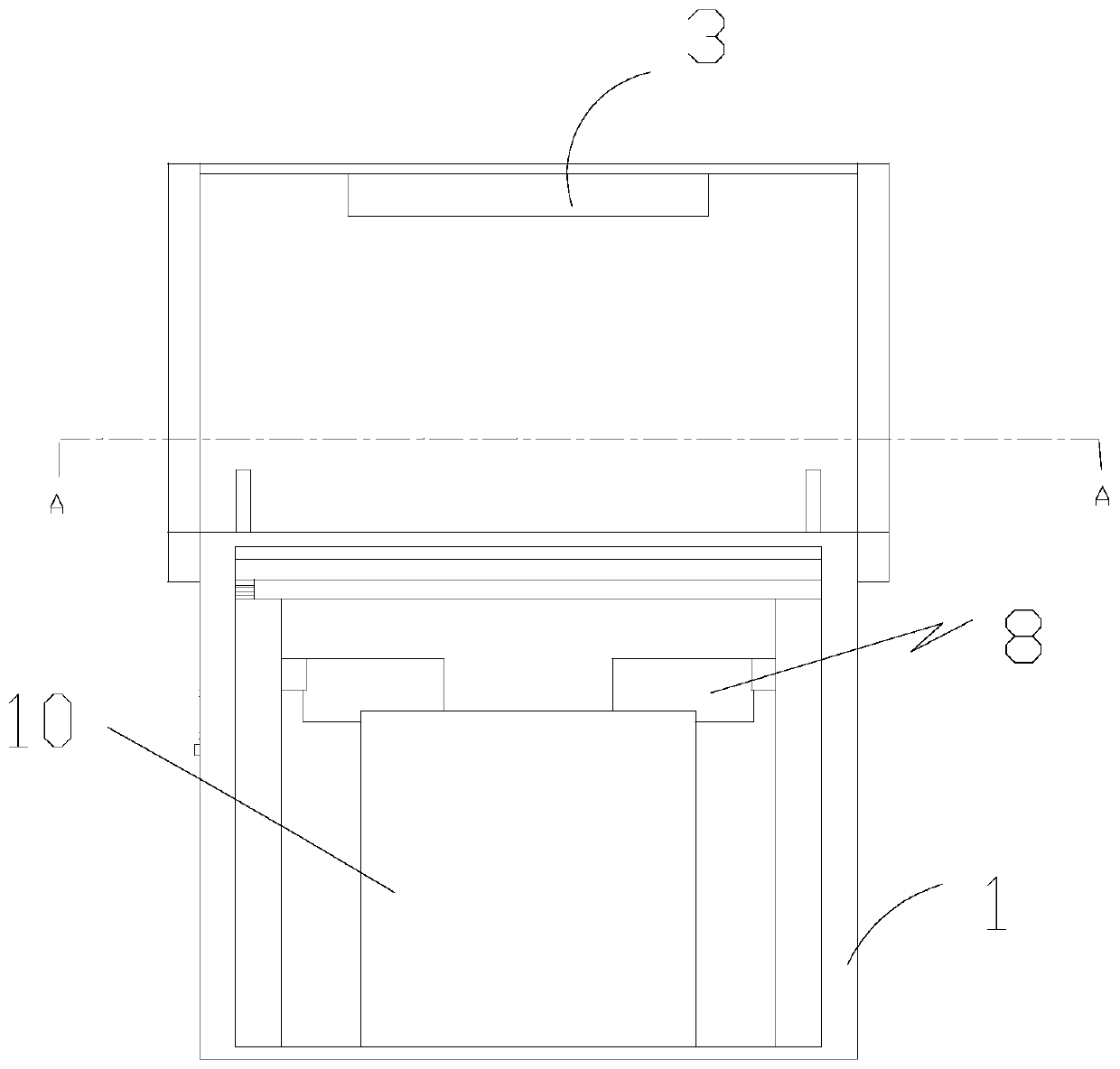

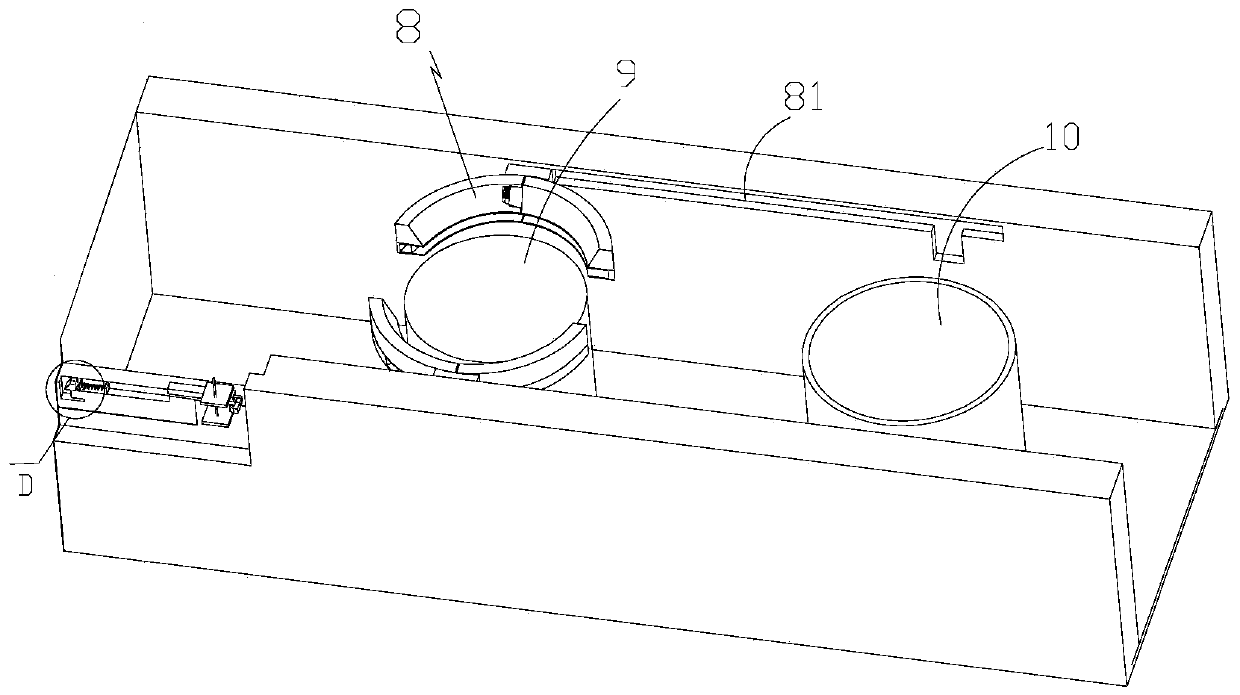

[0035] Such as Figure 1-12 As shown, a safe and reliable glass hot drilling and grinding equipment includes a housing 1, a lifting plate 2, a suction plate 3, a driving block 4, a feed port 5, a moving door 6, a driving device 7, a clamping device 8, a grinding Machine 9, cleaning cylinder 10; The driving device 7 includes a first spring 71, a first rack 72, a sliding groove 73, a mainspring 74, a gear 75, a guide block 76, and a pneumatic mechanism 77; the lifting plate 2 is arranged at The housing 1 is located directly above the feed inlet 5, and the lifting plate 2 is directly available on the market; the adsorption tray 3 is fixed on the lower end surface of the lifting plate 2, perpendicular to the clamping device 8 The driving block 4 is fixed on the lifting plate 2; the feed port 5 is opened on the housing 1; the movable door 6 is movably embedded in the feed port 5; the The driving device 7 is arranged in the housing 1; the clamping device 8 is movably embedded in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com