3D laser cutting device

A cutting device and three-dimensional laser technology, which are applied in laser welding equipment, devices for coating liquid on surfaces, and manufacturing tools, etc., can solve the problems of small pipe fittings containing waste and the inability to realize automatic separation of workpiece and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

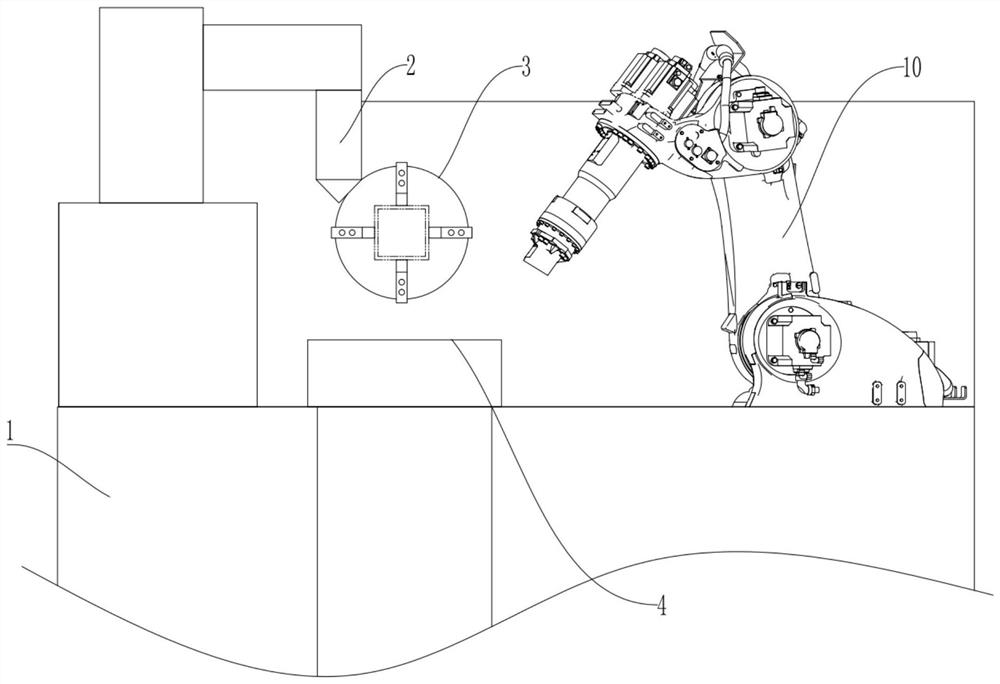

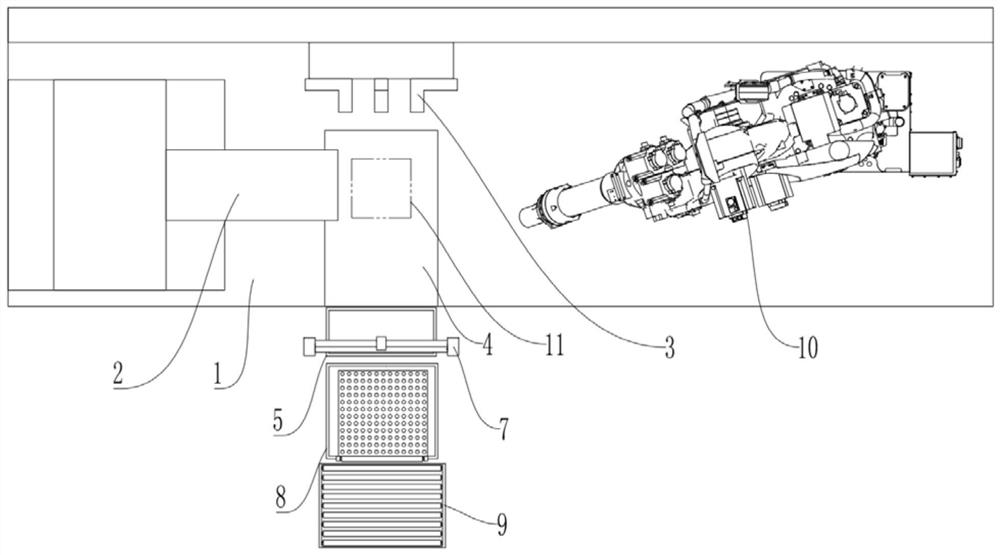

[0036] Embodiment one is basically as attached Figure 1 to Figure 4 Shown:

[0037] combine Figure 1 to Figure 3 , a three-dimensional laser cutting device, including a workbench 1, a laser cutter 2, a fixture 3, a receiving conveyor line 4, a collection box 5, a support rod 6, a toggle assembly 7, an oil tank 8, and a discharging conveyor line 9, and the receiving conveyor The line 4 adopts a belt-driven conveying line, and the laser cutter 2 and the fixture 3 are both installed on the workbench 1, and the manipulator 10 for transferring the workpiece to be processed to the fixture 3 is also installed on the workbench 1.

[0038] The upper surface of the receiving conveying line 4 is provided with refractory materials, the receiving conveying line 4 is located on the workbench 1 , and the receiving conveying line 4 is located below the laser cutter 2 .

[0039] combine Figure 4 , according to the transmission direction of the workpiece from left to right (the present em...

Embodiment 2

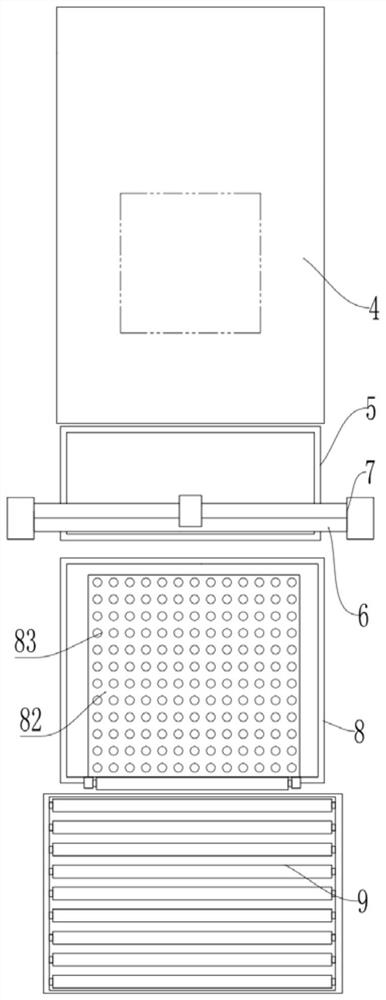

[0052] Embodiment two is basically as attached Figure 5 As shown, embodiment two has carried out following improvement on the basis of embodiment one:

[0053] The receiving conveying line 4 includes an annular conveyor belt 41, the surface of which is pasted with refractory material, and the upper surface of the conveyor belt 41 is covered with an annular metal mesh 42, and an elastic member is installed between the metal mesh 42 and the conveyor belt 41, and the elastic member Spring 43 is adopted; dust removal brush 44 is installed on the bottom of material receiving conveying line 4, and dust removal brush 44 is used for brushing off the sundries on metal mesh 42 and conveyer belt 41.

[0054] When adopting this embodiment, the small square tube 11 cut off by the laser cutter 2 directly falls onto the metal mesh 42, and the spring 43 makes the metal mesh 42 have better cushioning performance, which can reduce the impact caused by the falling of the small square tube 11. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com