Method for transforming heavy metal tailing slag into soil capable of growing plants

A technology for heavy metals and tailings slag, which is applied to the restoration of vegetation on the surface of heavy metal tailings ponds and the field of anti-erosion fertile soil layers. It can solve problems such as no specific guidance plan, and achieve the effects of restoring mine vegetation, reducing renovation costs, and maintaining water and soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

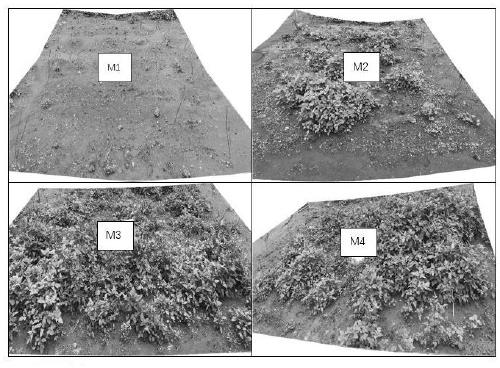

[0018] Example 1: The effect of different combinations of various materials required to transform heavy metal tailings slag into soil capable of growing plants on the ecological restoration of tailings ponds.

[0019] Test site: a polymetallic tailings pond in Guangxi, with a storage capacity of 1.24 million cubic meters and a height of 59 meters. It stopped being used in 2014 and is facing closure. There is no vegetation on the ground, and ecological restoration work is to be carried out. After collecting and testing the tailings pond waste residue, it was found that it contained high concentrations of heavy metal elements, such as: cadmium 12.1mg / kg, arsenic 3500mg / kg, lead 831mg / kg, zinc 1220mg / kg, etc. If treatment and restoration are not carried out, there will be a great risk of pollution to the downstream water body, soil, animals, plants and human body. Establish a 4m×5m test plot to verify the effect of different combinations of five materials on the ecological resto...

Embodiment 2

[0022] Example 2: 1) Tailings pond to be repaired: a mine tailings pond in Hebei, with a storage capacity of 500,000 cubic meters, has been out of use for 4 years, and the vegetation on the tailings slag surface is sparse. Among them, 410mg / kg of heavy metal copper, 2040mg / kg of zinc, and 14.99mg / kg of cadmium were measured, and 10 mu were selected for ecological restoration work. The tailings pond belongs to the flat land type tailings pond. 2) Purchase materials: 60 tons of sawdust, 20 tons of decomposed cow dung, 3.5 tons of clay, 5.5 tons of biomass power plant ash, 35 kg of MgO, 103 kg of CaO, 100 kg of polyacrylamide, 500 kg of urea, and 1000 kg of diammonium phosphate. 3) Equipment: 500L turning drum mixer, 50KW Raymond mill, mechanical hopper, fan, dust collector.

[0023] The method for transforming heavy metal tailings slag into soil capable of growing plants is characterized in that it comprises the following process steps:

[0024] (1) Prepare material A, materia...

Embodiment 3

[0027] Example 3: 1) Tailings pool to be repaired: a metal mine tailings pool in central my country, with a total volume of 300,000 cubic meters of slag and sparse vegetation on the surface. Among them, 2250mg / kg of heavy metal lead, 2040mg / kg of zinc, and 4.32mg / kg of cadmium were measured, and 5 mu were selected to carry out ecological restoration work. 2) Purchase materials: 50 tons of sawdust, 15 tons of decomposed chicken manure, 1.6 tons of clay, 2.7 tons of biomass power plant ash, 24 kg of MgO, 78 kg of CaO, 50 kg of polyacrylamide, 250 kg of urea, 500 kg of diammonium phosphate . 3) Equipment: 500L turning drum mixer, 50KW Raymond mill, mechanical hopper, fan, dust collector.

[0028] The method for transforming heavy metal tailings slag into soil capable of growing plants is characterized in that it comprises the following process steps:

[0029] (1) Prepare material A, material B, material C, material D, and material E.

[0030](1) Preparation material A: collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com