Automatic powder spraying device high in spraying efficiency

An automatic spraying and high-efficiency technology, applied in spraying devices, spraying devices with movable outlets, spray booths, etc., can solve the problems of low efficiency of manual spraying, uneven spraying, and easy inhalation of paint by workers, so as to save energy consumption and Labor cost, reducing powder waste, and improving the effect of spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

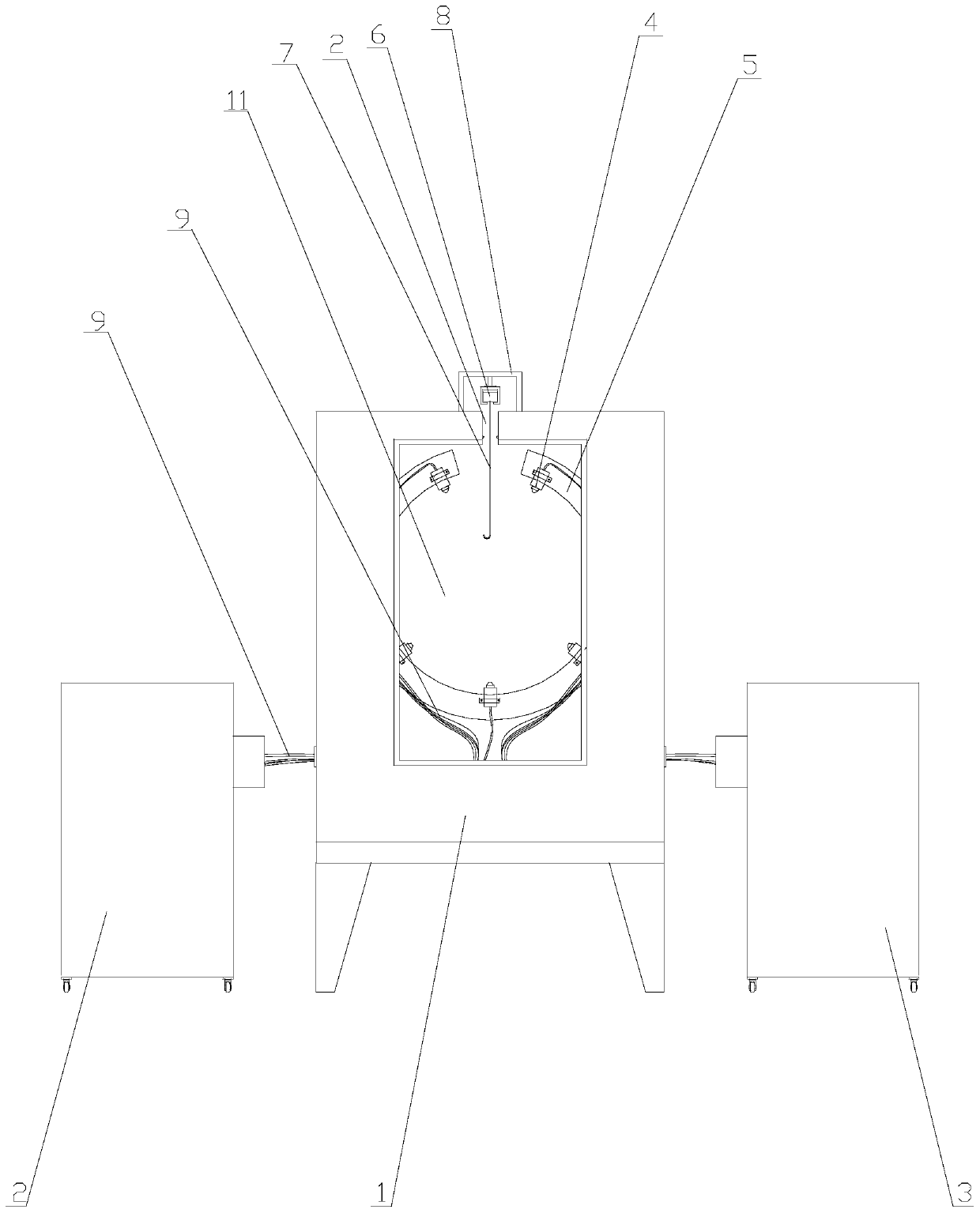

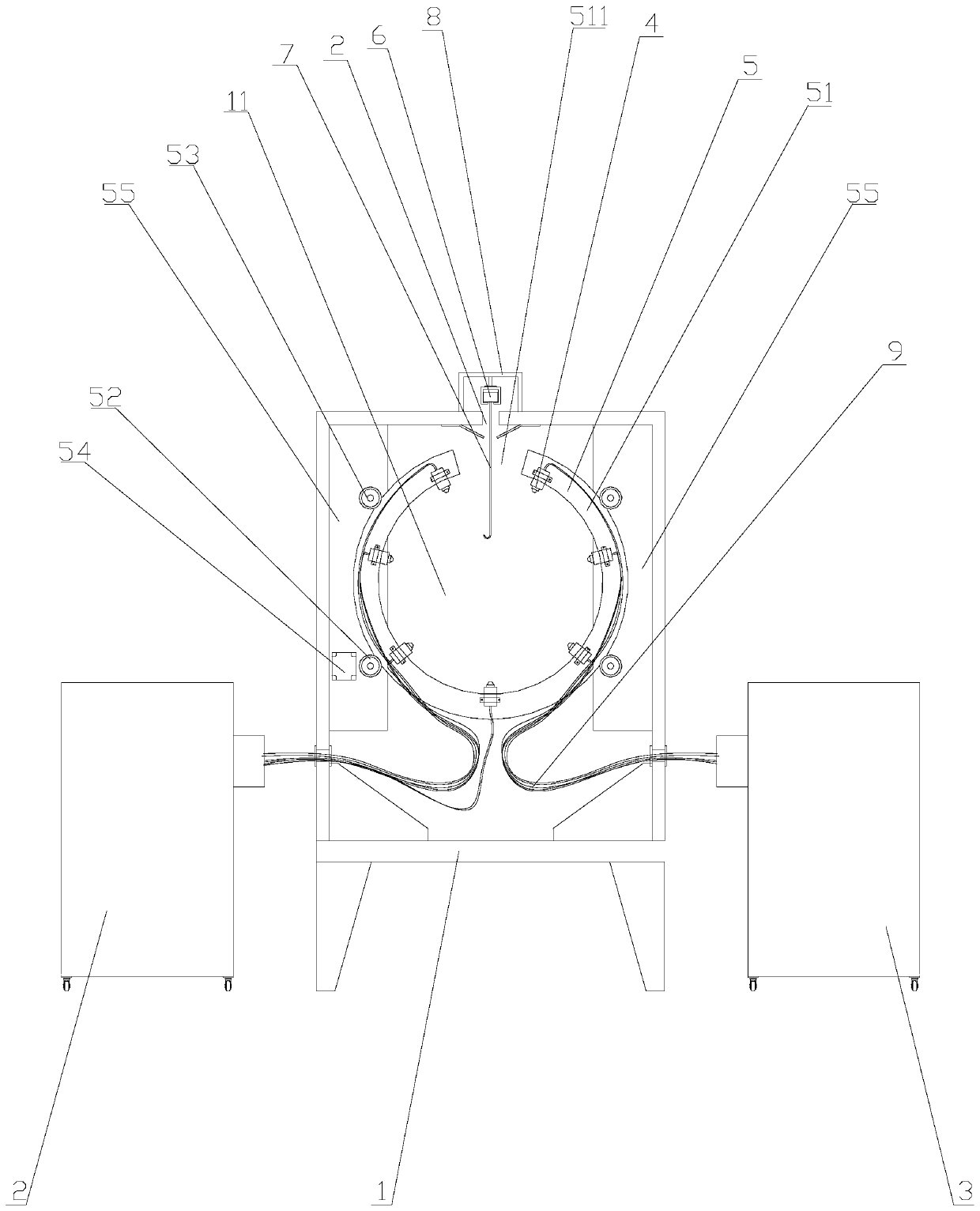

[0022] refer to figure 1 , figure 2 , image 3 and Figure 4 , a powder automatic spraying device with high spraying efficiency according to the present invention, comprising a powder spraying box 1, a first powder box 2, a second powder box 3, several electrostatic powder spraying guns 4, a powder spraying gun swing device 5, and a conveying rail 6 , a number of spraying parts hooks 7, a transport rail protection shell 8, a powder delivery hose 9, the powder spraying box 1 is provided with a spraying chamber 11, the two ends of the spraying chamber 11 are arranged, and the described spraying chamber 11 The top is provided with an upper opening groove 12 that can be matched with the conveying rail 6, and the upper end of the upper opening groove 12 is provided with a conveying rail protective shell 8, and the conveying rail 6 is arranged inside the conveying rail protective shell 8, and the conveying The upper end of the rail 6 is fixedly connected with the inner top wall ...

Embodiment 2

[0024] On the basis of Embodiment 1, there are two powder spraying boxes 1, the two powder spraying boxes 1 are symmetrically arranged, and the upper end is provided between the two powder spraying boxes 1. The drying box 10 , the conveying rails 6 of the two powder spraying boxes 1 are connected to the drying box 10 , and the two powder spraying boxes 1 share one drying box 10 .

[0025] Working process of the present invention:

[0026] The powder automatic spraying device with high spraying efficiency of the present invention connects the conveying rail 6 of the equipment with the powder spraying line equipment during the working process, the workpiece to be sprayed is hung on the spraying part hook 7, and the conveying rail 6 transports the workpiece to In the spraying chamber 11, the electrostatic powder spray gun 4 sprays the powder, the driving motor 54 of the powder spray gun swing device 5 drives the rotating ring driving wheel 52 to rotate, and the rotating ring driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com