Soilless culture method for vegetables

A soilless cultivation and vegetable technology, applied in soilless cultivation, cultivation, botanical equipment and methods, etc., can solve the problems of low germination rate and seedling rate, affecting vegetable output, accumulation of germs and insect eggs, etc. Achieve the effect of increasing the emergence rate and seedling rate, reducing the infection rate of pathogens, and promoting the growth of germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

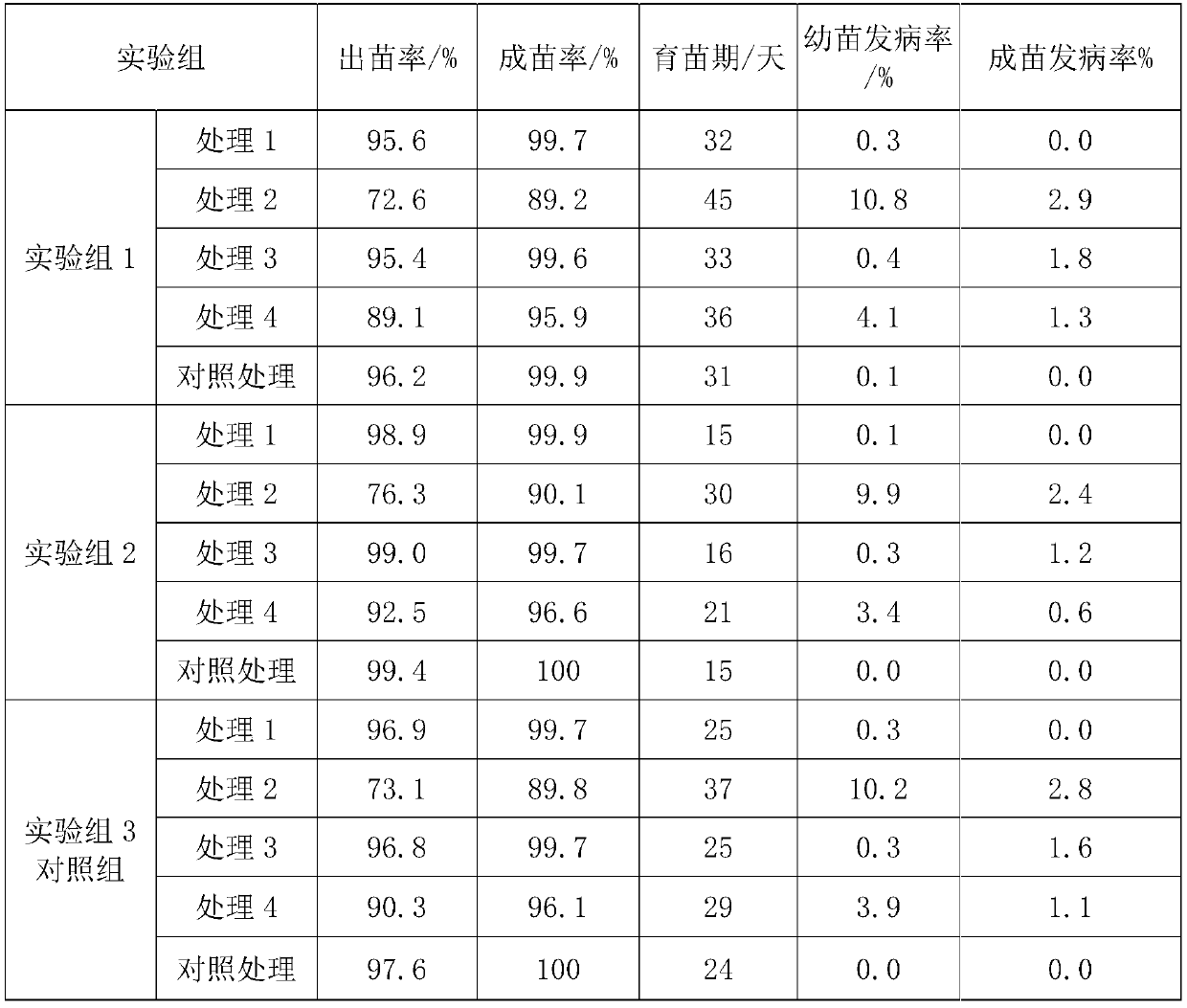

Examples

Embodiment 1

[0027] Embodiment 1-a kind of method of soilless cultivation vegetables, comprises the steps:

[0028] (1) Preparation of seedling-raising substrate: seedling-raising substrate includes: 30 parts of cotton stalk scraps, 20 parts of corn stalks, 10 parts of bagasse, 15 parts of tea bagasse, 3 parts of compound fermentation material, 30 parts of vermiculite and 25 parts of peat, according to The ratio of parts by weight is mixed: the composite fermented material is mixed with pine nut shells, chestnut shells, rice hulls and cottonseed shells according to the mass ratio of 1:1:5:5, and made of 10kg / m 3 Composite bacterial agent is obtained by decomposing and fermenting, and its moisture content is 20%;

[0029] (2) Sowing seedlings: in the seedling shed, add the seedling substrate to the seedling trough, the thickness is 15cm, after drenching with water, the vegetable seeds are sown in the cultivation substrate in the seedling trough, and then covered with a thickness of 1cm seed...

Embodiment 2

[0034] Embodiment 2-a kind of method of soilless cultivation vegetables, comprises the steps:

[0035] (1) Preparation of seedling-raising substrate: seedling-raising substrate includes: 50 parts of cotton stalk scraps, 30 parts of corn stalks, 20 parts of bagasse, 30 parts of tea bagasse, 4 parts of compound fermentation materials, 40 parts of vermiculite and 35 parts of peat, according to Mixed parts by weight: the composite fermented material is mixed with pine nut shells, chestnut shells, rice hulls and cottonseed shells in a mass ratio of 3:3:7:7, and mixed with 15kg / m 3 The composite bacterial agent is obtained by decomposing and fermenting, and its water content is 25%. The composite bacterial agent includes yeast, actinomycetes, bacillus and lactic acid bacteria;

[0036] (2) Sowing seedlings: in the seedling shed, add the seedling substrate to the seedling tank, the thickness is 20cm, after soaking with water, the vegetable seeds are soaked in 0.05% chitosan solution ...

Embodiment 3

[0041] Embodiment 3-a kind of method of soilless cultivation vegetables, comprises the steps:

[0042] (1) Preparation of seedling-raising substrate: seedling-raising substrate includes: 40 parts of cotton stalk scraps, 25 parts of corn stalks, 15 parts of bagasse, 25 parts of tea bagasse, 3.5 parts of compound fermentation material, 35 parts of vermiculite and 30 parts of peat, according to The ratio of parts by weight is mixed: the composite fermented material is mixed according to the mass ratio of 2:2:5:5 by pine nut shells, chestnut shells, rice hulls and cottonseed shells, and is composed of 14kg / m 3 The composite bacterial agent is obtained by decomposing and fermenting, and its water content is 23%. The composite bacterial agent includes yeast, actinomycetes, bacillus and lactic acid bacteria;

[0043] (2) Sowing seedlings: In the seedling shed, add the seedling substrate to the seedling tank, the thickness is 18cm, after soaking with water, the vegetable seeds are soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com