Flexible package lithium battery core formation process

A lithium battery cell and flexible packaging technology, which is applied in the field of flexible packaging lithium battery cell formation technology, can solve the problems of difficulty in realizing industrialization, increase production costs, and high equipment requirements, and achieve the effects of reducing the internal resistance of the battery cell, improving production efficiency, and improving cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

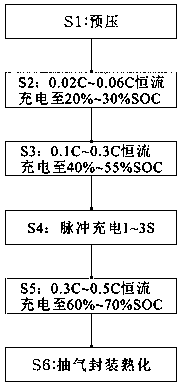

[0045] S1: Preloading: fully soak the cell after liquid injection, then fix it on the high-temperature chemical forming fixture, apply 0.2MPa pressure for preloading, set the temperature at 60°C, and keep it for 5 minutes;

[0046] S2: The first formation charge: charge the pre-pressed cell to 25% SOC with a constant current of 0.03C, and the pressure is 0.2MPa, and hold the pressure for 3 minutes after completion;

[0047] S3: The second formation charging: the cell is charged at a constant current of 0.1C to 45% SOC, the pressure is 0.4MPa, and the pressure is kept for 60S after completion;

[0048] S4: Pulse charging: pulse discharge the battery for 3S, and put it aside for 5S;

[0049] S5: The third formation charge: the cell is charged to 65% SOC with a constant current of 0.3C, and the pressure is 0.7MPa, then repeat step S4;

[0050] S6: Evacuation packaging curing: lower the high-temperature fixture to room temperature, remove the battery cells, perform degassing pack...

Embodiment 2

[0052] S1: Preloading: fully soak the cell after liquid injection, then fix it on the high-temperature chemical forming fixture, apply 0.2MPa pressure for preloading, set the temperature at 60°C, and keep it for 5 minutes;

[0053] S2: The first formation charge: Charge the pre-pressed cell to 27% SOC with a constant current of 0.04C, and the pressure is 0.2MPa, and hold the pressure for 3 minutes after completion;

[0054] S3: The second formation charging: the cell is charged to 55% SOC with a constant current of 0.3C, and the pressure is 0.5MPa. After completion, the pressure is kept for 60S;

[0055] S4: Pulse charging: pulse discharge the battery for 3S, and put it aside for 5S;

[0056] S5: The third formation charging: the cell is charged to 70% SOC with a constant current of 0.4C, and the pressure is 0.8MPa, then repeat step S4;

[0057] S6: Evacuation packaging curing: lower the high-temperature fixture to room temperature, remove the battery cells, perform degassing...

Embodiment 3

[0059] S1: Preloading: fully soak the cell after liquid injection, then fix it on the high-temperature chemical forming fixture, apply 0.3MPa pressure for preloading, set the temperature at 60°C, and keep it for 5 minutes;

[0060]S2: The first formation charging: charge the pre-pressed cell to 30% SOC at a constant current of 0.05C, and the pressure is 0.2MPa, and hold the pressure for 3 minutes after completion;

[0061] S3: The second formation charging: the cell is charged to 50% SOC with a constant current of 0.2C, and the pressure is 0.4MPa. After completion, the pressure is kept for 60S;

[0062] S4: Pulse charging: pulse discharge the battery for 3S, and put it aside for 5S;

[0063] S5: The third formation charging: the cell is charged to 60% SOC with a constant current of 0.3C, and the pressure is 0.6MPa, and then repeat step S4;

[0064] S6: Evacuation packaging curing: lower the high-temperature fixture to room temperature, remove the battery cells, perform degass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com