Formation method for lithium ion battery

A lithium ion battery and a chemical formation method technology, applied in the field of lithium ion battery chemical formation, can solve the problems of complex process, high energy consumption, poor stability, etc., and achieve the effects of high capacity, low energy consumption, and low expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

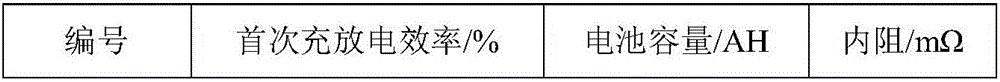

Embodiment 1

[0019] The formation method of the lithium-ion battery of this embodiment includes: charging and forming the lithium-ion battery after the liquid injection and standing at a temperature of 35°C and a vacuum of 70KPa; the charging process is divided into three stages: the first The charging current in the first stage is 0.05C, and the charging time is 2h; the charging current in the second stage is 0.1C, and the charging time is 2h; the charging current in the third stage is 0.25C, and the charging time is 2h.

Embodiment 2

[0021] The formation method of the lithium-ion battery of the present embodiment includes: charging and forming the lithium-ion battery after the liquid injection and standing at a temperature of 45°C and a vacuum of 75KPa; the charging process is divided into two stages: the first The charging current in the first stage is 0.1C, and the charging time is 2h; the charging current in the second stage is 0.2C, and the charging time is 2h.

Embodiment 3

[0023] The formation method of the lithium-ion battery of the present embodiment includes: charging and forming the lithium-ion battery after the liquid injection and standing at a temperature of 55°C and a vacuum of 80KPa; the charging process is divided into three stages: the first The charging current in the first stage is 0.05C, and the charging time is 2h; the charging current in the second stage is 0.1C, and the charging time is 2h; the charging current in the third stage is 0.25C, and the charging cut-off voltage is 3.65V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com