Lithium-ion battery cathode glue and preparation method thereof

A lithium-ion battery, positive electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow dissolution speed, difficult to disperse the binder uniformly, and the molecular chain of the glue at stirring speed. Volatile, improve dissolution rate and dispersion uniformity, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

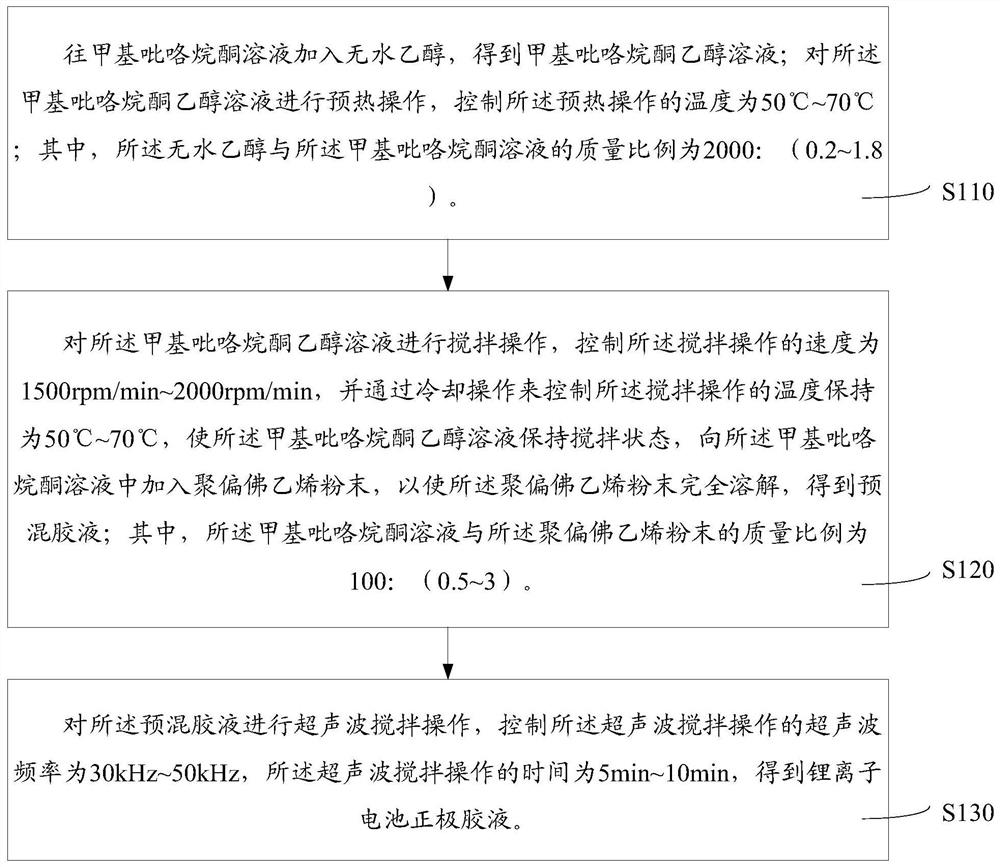

[0028] For an implementation, see figure 1 , a preparation method of lithium-ion battery positive electrode glue, comprising the following steps:

[0029] S110, adding absolute ethanol to the methylpyrrolidone solution to obtain a methylpyrrolidone ethanol solution; performing a preheating operation on the methylpyrrolidone ethanol solution, controlling the temperature of the preheating operation to be 50° C. to 70° C.; wherein, the The mass ratio of the absolute ethanol to the methylpyrrolidone solution is 2000:(0.2-1.8).

[0030] S120, performing a stirring operation on the methylpyrrolidone ethanol solution, controlling the speed of the stirring operation to be 1500rpm / min-2000rpm / min, and controlling the temperature of the stirring operation to be maintained at 50°C-70°C through a cooling operation, The methylpyrrolidone ethanol solution is kept in a stirring state, and polyvinylidene fluoride powder is added to the methylpyrrolidone solution to completely dissolve the po...

Embodiment 1

[0049] S111, adding 0.2 g of absolute ethanol to 1000 g of methylpyrrolidone solution to obtain a methylpyrrolidone ethanol solution; performing a preheating operation on the methylpyrrolidone ethanol solution, and controlling the temperature of the preheating operation to be 50° C.

[0050] S121, performing a stirring operation on the methylpyrrolidone ethanol solution, controlling the speed of the stirring operation to be 2000 rpm / min, keeping the methylpyrrolidone ethanol solution in a stirring state, and performing a cooling operation to control the temperature of the stirring operation Keep it at 50°C, add polyvinylidene fluoride powder into the methylpyrrolidone solution by adding while stirring, and control the adding speed of the polyvinylidene fluoride powder: 1000g*5% / 10=5g / min, The time for the high-speed stirring operation is controlled to be 10 minutes, so that the polyvinylidene fluoride powder is completely dissolved to obtain a premixed glue solution. Wherein, ...

Embodiment 2

[0053] S112, adding 1.8 g of absolute ethanol to 1000 g of methylpyrrolidone solution to obtain a methylpyrrolidone ethanol solution; performing a preheating operation on the methylpyrrolidone ethanol solution, and controlling the temperature of the preheating operation to be 70° C.

[0054] S122, performing a stirring operation on the methylpyrrolidone ethanol solution, controlling the speed of the stirring operation to be 1500 rpm / min, keeping the methylpyrrolidone ethanol solution in a stirring state, and performing a cooling operation to control the temperature of the stirring operation Keep it at 70°C, add polyvinylidene fluoride powder into the methylpyrrolidone solution by adding while stirring, and control the adding speed of the polyvinylidene fluoride powder: 1000g*30% / 30=10g / min, The time for the high-speed stirring operation is controlled to be 30 minutes, so that the polyvinylidene fluoride powder is completely dissolved to obtain a premixed glue solution. Wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com