Heating device and method for preparing diffusion alloy powder for detachable tube furnace

A technology of diffusion alloy and heating device is applied in the field of preparation of diffusion alloy powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

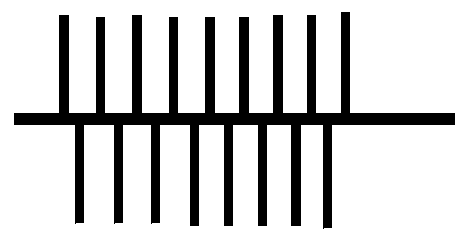

Image

Examples

Embodiment Construction

[0030] In order to better illustrate the present invention and facilitate understanding of the technical solution of the present invention, the present invention will be further described in detail below. However, the following embodiments are only simple examples of the present invention, and do not represent or limit the protection scope of the present invention, and the protection scope of the present invention shall be determined by the claims.

[0031] The invention provides a powder heating device for a detachable tube furnace, which is characterized in that the device includes a furnace tube (1), a flange (2), an air outlet (3), a stirring structure (4), an inlet Air port (5) and motor (6). Among them, the flange (2) is used to fix the furnace tube on the tubular furnace body, and the stirring structure (4) is connected to the motor (6) and fixed on the flange (2) so that the stirring structure (4) is placed on the furnace tube (1 ) on the central axis. Air inlet (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com