Waste liquid incineration equipment for pesticide production

A waste liquid and pesticide technology, which is applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of incomplete treatment of high-concentration pesticide waste liquid and the need to improve environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

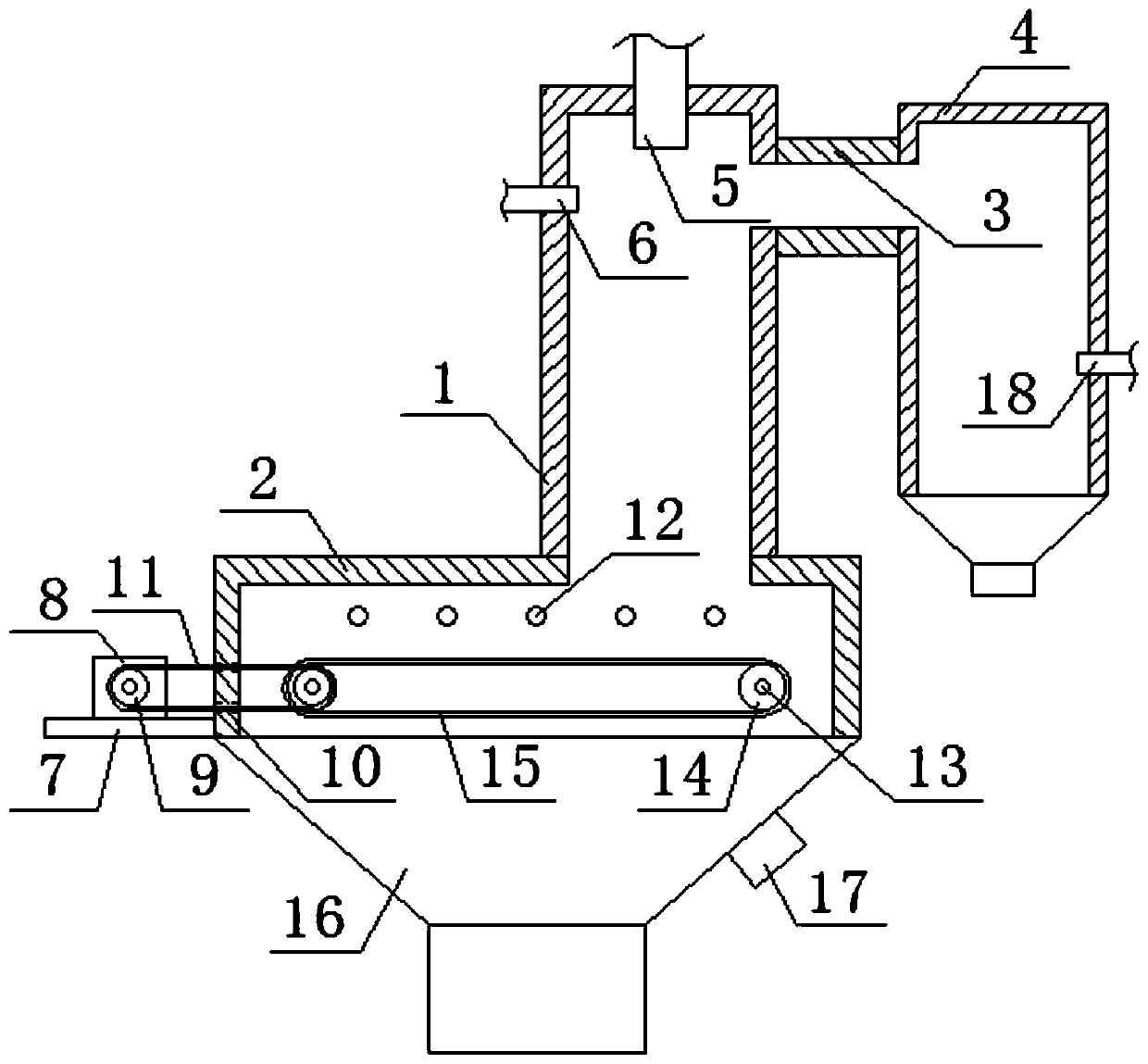

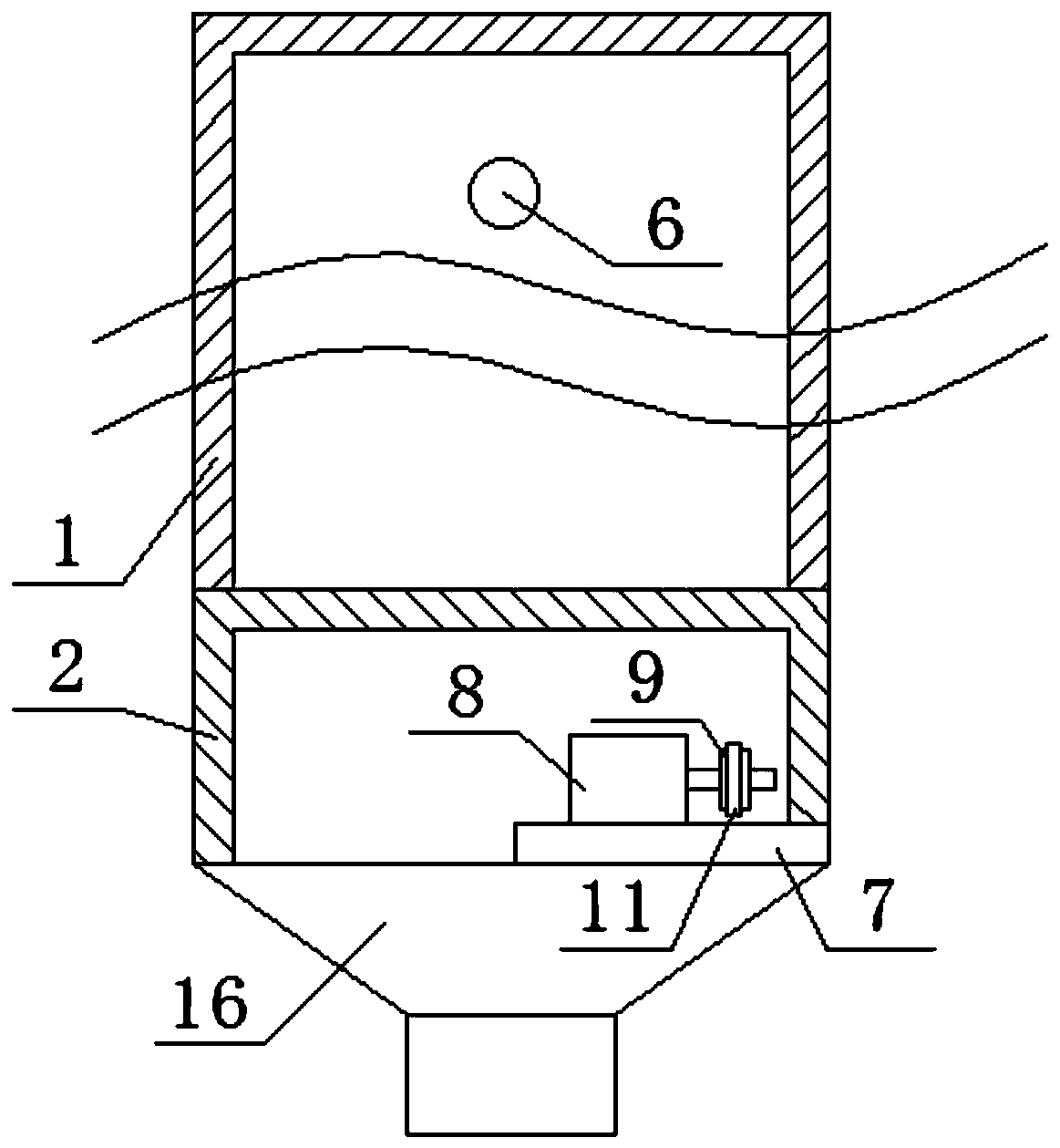

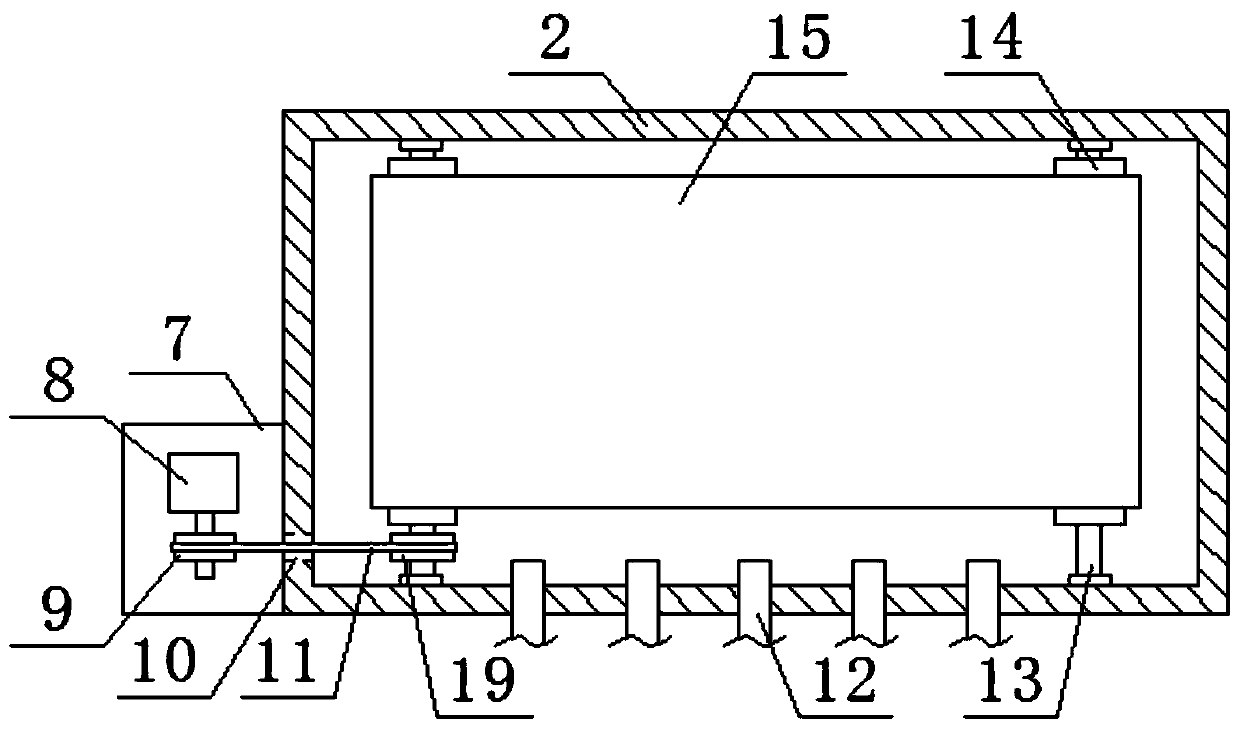

[0021] refer to Figure 1-3 , a waste liquid incineration device for pesticide production, comprising a first combustion chamber 1, a second combustion chamber 2 is fixedly installed on the bottom of the first combustion chamber 1, and a channel 3 is fixedly installed on one side of the first combustion chamber 1 One end, the other end of the passage 3 is fixedly installed with an auxiliary combustion chamber 4, the top center of the first combustion chamber 1 is fixedly installed with a first burner 5, and the side of the first combustion chamber 1 away from the passage 3 is fixedly installed with a high-pressure nozzle 6 , and both the first burner 5 and the high-pressure nozzle 6 extend into the first combustion chamber 1, the bottom of one side of the second combustion chamber 2 is fixedly installed with a support plate 7, and the top of the support plate 7 is fixedly installed with a motor 8. 8 is fixedly sleeved with a drive wheel 9 on the output shaft of 8, and the seco...

Embodiment 2

[0027] refer to Figure 1-3 , a waste liquid incineration device for pesticide production, comprising a first combustion chamber 1, a second combustion chamber 2 is fixedly installed on the bottom of the first combustion chamber 1, and a channel 3 is fixedly installed on one side of the first combustion chamber 1 One end, the other end of the passage 3 is fixedly installed with an auxiliary combustion chamber 4, the top center of the first combustion chamber 1 is fixedly installed with a first burner 5, and the side of the first combustion chamber 1 away from the passage 3 is fixedly installed with a high-pressure nozzle 6 , and both the first burner 5 and the high-pressure nozzle 6 extend into the first combustion chamber 1, the bottom of one side of the second combustion chamber 2 is fixedly installed with a support plate 7, and the top of the support plate 7 is fixedly installed with a motor 8. 8 is fixedly sleeved with a drive wheel 9 on the output shaft of 8, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com