HTEE series high-temperature infrared radiation coating and use method thereof

A technology of high-temperature infrared and radiation coatings, applied in combustion methods, fireproof coatings, coatings, etc., can solve the problems of low energy utilization rate of steam injection boilers, early development of heavy oil in oil fields, and affecting boiler operating efficiency, etc., to reduce heat preservation Effects of layer peeling, heat reduction, and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

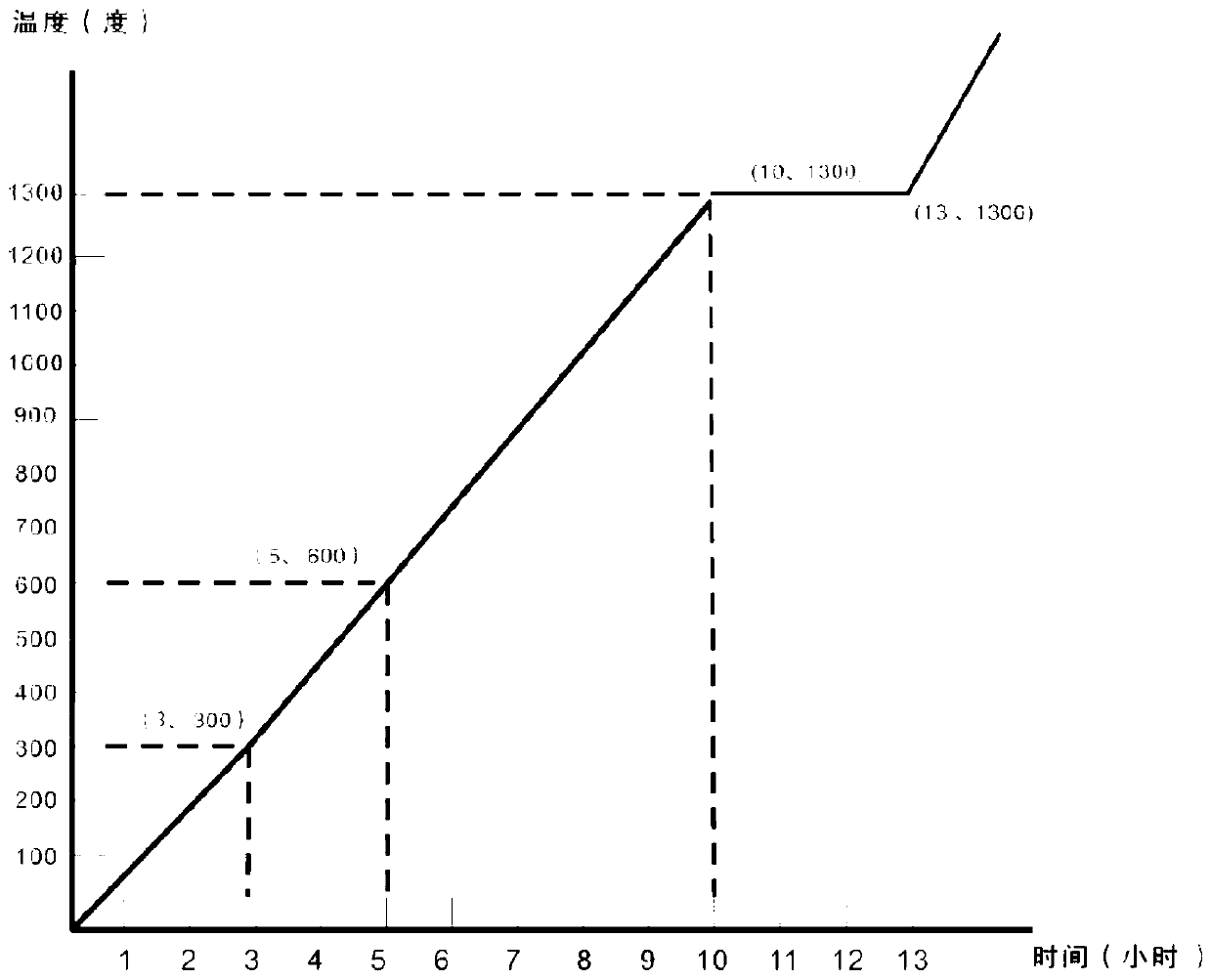

Image

Examples

Embodiment example 1

[0047] A kind of HTEE series high-temperature infrared radiation coating, comprises following preparation steps:

[0048] (1) Mix the components according to the following mass percentage: ZrO 20%, activated alumina micropowder 5%, TiO 2 15%, Al(OH) 3 5%, CoO 20% into the stirring device;

[0049] (2) Add the following components by mass percentage: 15% of zirconia liquid slurry, 15% of solvent, and 5% of water are mixed and stirred, and soaked;

[0050] (3) After the soaking time is up, put the material into the mixer to stir, adjust the mixer to 45°C, react for 60 minutes and cool to 25°C;

[0051] (4) The flow line of the sampling liquid in the mixer is uninterrupted when it reaches more than 150mm, stop stirring, and put the material into a 185-400 mesh screen for filtration;

[0052] (5) Measuring after filtering and packing into barrels.

[0053] In the described step (1), ZrO is a nano zirconia powder, and the nano zirconia comprises the following preparation step...

Embodiment example 2

[0063] A kind of HTEE series high-temperature infrared radiation coating, comprises following preparation steps:

[0064] (1) Mix the components according to the following mass percentage: ZrO 17%, activated alumina micropowder 4.5%, TiO 2 17%, Al(OH) 3 4%, CoO 22% into the stirring device;

[0065] (2) Add the following components by mass percentage: 16% of zirconia liquid slurry, 16.5% of solvent, and 3% of water are mixed and stirred, soaked;

[0066] (3) After the soaking time is up, put the material into the mixer to stir, adjust the mixer to 48°C, react for 70 minutes and cool to 25°C;

[0067] (4) The flow line of the sampling liquid in the mixer is uninterrupted when it reaches more than 150mm, stop stirring, and put the material into a 185-400 mesh screen for filtration;

[0068] (5) Measuring after filtering and packing into barrels.

[0069] In the described step (1), ZrO is a nano zirconia powder, and the nano zirconia comprises the following preparation steps:...

Embodiment example 3

[0079] A kind of HTEE series high-temperature infrared radiation coating, comprises following preparation steps:

[0080] (1) Mix the components according to the following mass percentage: ZrO 25%, activated alumina micropowder 4.5%, TiO 2 12%, Al(OH) 3 4%, CoO 16% into the stirring device;

[0081] (2) Add the following components by mass percentage: 13% of zirconia liquid slurry, 18.5% of solvent, and 7% of water are mixed and stirred, soaked;

[0082] (3) After the soaking time is up, put the material into the mixer to stir, adjust the mixer to 45°C, react for 60 minutes and cool to 25°C;

[0083] (4) The flow line of the sampling liquid in the mixer is uninterrupted when it reaches more than 150mm, stop stirring, and put the material into a 185-400 mesh screen for filtration;

[0084] (5) Measuring after filtering and packing into barrels.

[0085] In the described step (1), ZrO is a nano zirconia powder, and the nano zirconia comprises the following preparation steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com