Cement anti-erosion agent for high-pressure jet grouting and use method thereof

A high-pressure jetting, anti-erosion technology, applied in the field of cement grouting, can solve the problems of short setting time, low erosion resistance, too fast setting, etc., and achieve extended setting time, strong erosion resistance, and long setting time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

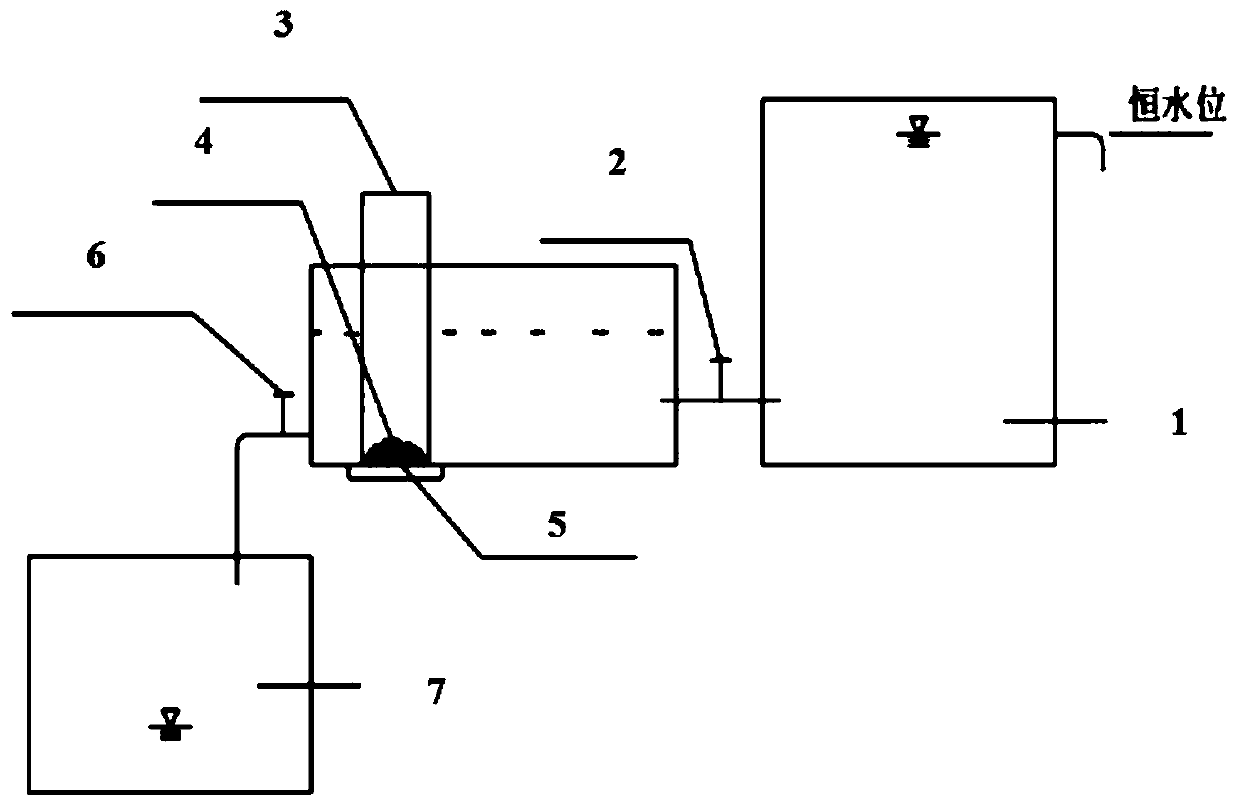

Image

Examples

Embodiment 1-6

[0047] A cement anti-erosion agent for high-pressure jet grouting, which is composed of 65-93 parts by weight of aluminum-containing inorganic salt, 5-12 parts by weight of thickener, 2-5 parts by weight of mineral admixture, and 7-18 parts by weight of activator. Composed in parts by weight, wherein the aluminum-containing inorganic salt is sodium metaaluminate and aluminum sulfate, the thickener is guar gum and polyacrylamide, the mineral admixture is granulated blast furnace slag powder and silica fume purchased in the market, and the activator is Sodium Sulfate and Sodium Carbonate. The specific raw material parts by weight of the cement anti-erosion agent described in Examples 1-6 are shown in Table 1.

[0048] Table 1

[0049] Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Sodium metaaluminate 42 35 42 42 42 35 Aluminum sulfate 38 44 40 40 36 46 Guar Gum 2 2 2 4 2 5 polyacrylamide 3 3 3 3 5 3...

Embodiment 7

[0051] The cement anti-erosion agent prepared in Examples 1-6 is used, and the specific method of use is: the cement slurry and the cement anti-erosion agent aqueous solution are used for double-pipe grouting, and the two materials are simultaneously injected into the formation by high-pressure jet grouting , wherein the weight ratio of cement to cement anti-erosion agent is 1:0.03. The water-cement ratio of the cement slurry used is 0.8, that is, the ratio of the mass of cement to the mass of water in the cement slurry is 100:80. In the cement anti-erosion agent aqueous solution, the weight ratio of the cement anti-erosion agent to water is 1:4.

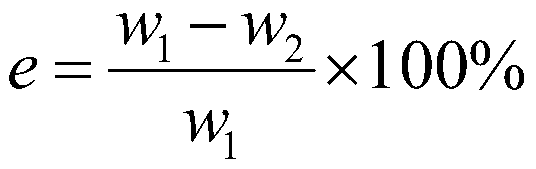

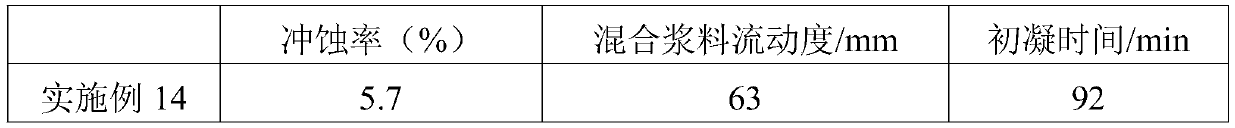

[0052] The erosion rate, fluidity, and initial setting time of the mixture of the above-mentioned cement slurry and the cement anti-erosion agent aqueous solution are detected. At the same time, only the cement slurry with a water-cement ratio of 0.8 is used for high-pressure jet grouting as a blank example. The test results are s...

Embodiment 8-13

[0056] Change the raw material composition of the cement anti-erosion agent described in Example 1, wherein the aluminum-containing inorganic salt is potassium metaaluminate, aluminum sulfate and aluminum hydroxide, and the thickener is cassava flour and polymer water-absorbing resin (Shandong Youso Chemical Co., Ltd. WHS-700 type resin), the mineral admixture is particle diameter 100-300 order superfine fly ash, and activator is calcium sulfate and sodium silicate, the specific raw material of cement anti-erosion agent described in embodiment 8-13 The parts by weight are shown in Table 3.

[0057] table 3

[0058] Example 8 Example 9 Example 10 Example 11 Example 12 Example 13 Potassium metaaluminate 25 35 37 30 25 25 Aluminum sulfate 30 20 25 30 30 30 Aluminum hydroxide 13 16 15 12 15 18 tapioca flour 6 6 6 5 5 5 Absorbent resin 3 3 3 7 7 7 fly ash 5 2 4 2 5 2 Calcium sulfate 8 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com