Method for treating spent catalyst noble metal recovery wastewater

A technology for precious metal recovery and spent catalysts, applied in chemical instruments and methods, filtration treatment, metallurgical wastewater treatment, etc., can solve problems such as silicon pollution, and achieve the effect of reducing the volume of wastewater and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

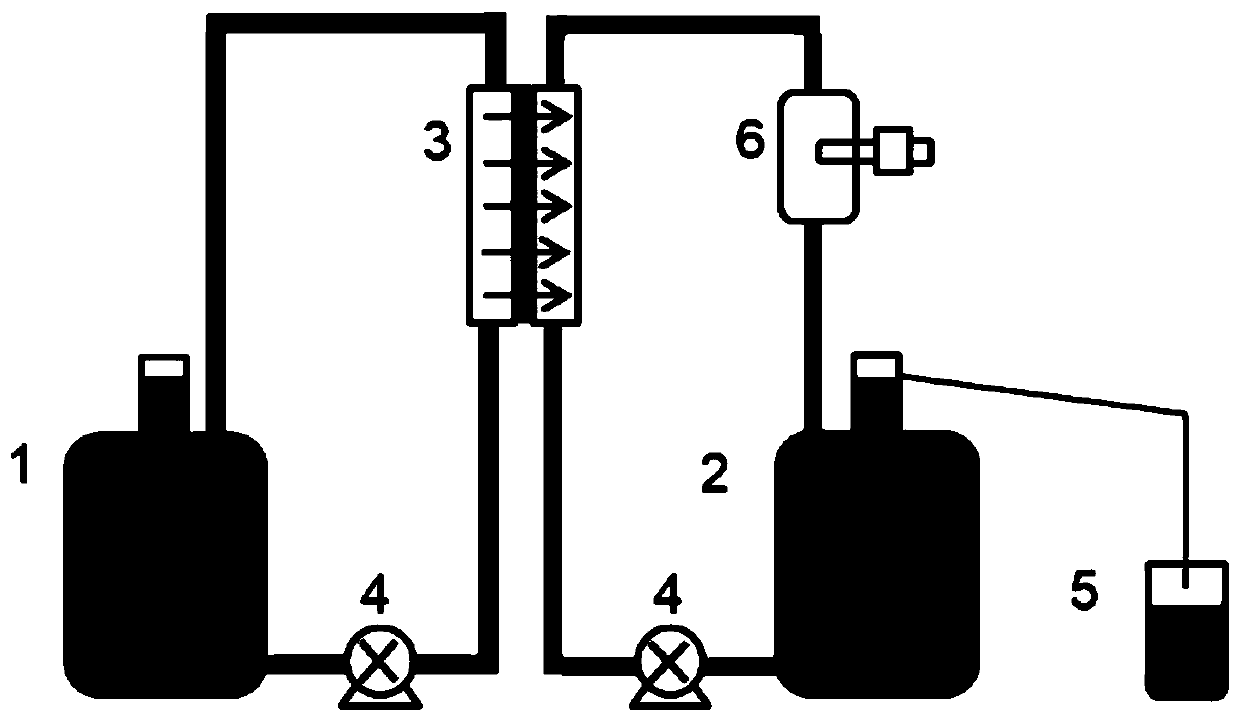

Method used

Image

Examples

Embodiment 1

[0039] Precious metal refining is to process and purify the impurity-containing and low-purity crude materials to obtain high-purity substances. Refining is one of the steps of purifying and recovering precious metals from spent catalysts. This case takes the treatment of actual spent catalyst platinum recovery and refining wastewater as an example to illustrate the features and advantages of the present invention.

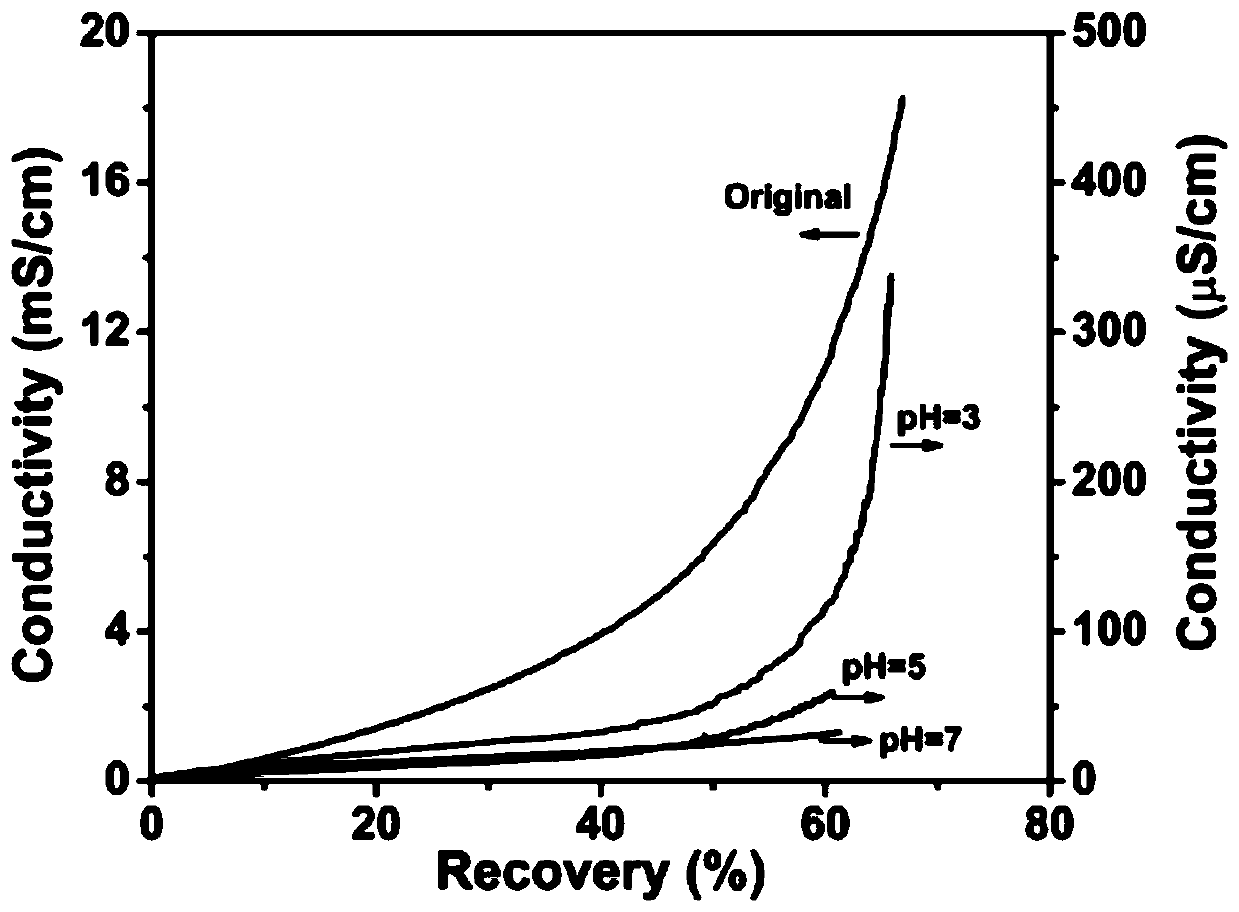

[0040] The actual exhausted catalyst platinum recovery and refining wastewater produced by a precious metal resource recovery company is used as the research object, and its water quality indicators are shown in Table 1 below. The data in the table shows that the pH of refining wastewater is low and the salt content is high. Using conventional reverse osmosis or nanofiltration technology requires high operating pressure and is technically infeasible. Neutralize the sediment to reduce the content of high-valent metal ions in the wastewater. At the same time, the ge...

Embodiment 2

[0048] Silver is an important catalytic material and can be used as an active component of many oxidation reaction catalysts. Silver is an active component in the industrial production of ethylene oxide catalysts, and its mass content accounts for 15% to 40% of the catalyst. Therefore, rational use of limited resources and comprehensive recovery of secondary materials have attracted more and more attention. This case is based on the waste water produced by recycling silver from the spent catalyst as the research object. The water quality of the silver recovered from the spent catalyst is shown in Table 3. The characteristics and advantages of the present invention are illustrated by using MD to treat the waste water produced by silver recovery.

[0049] This embodiment takes the waste water produced by a precious metal resource recycling company to reclaim silver from the spent catalyst as the research object, and the water quality of the spent catalyst silver recovery is show...

Embodiment 3

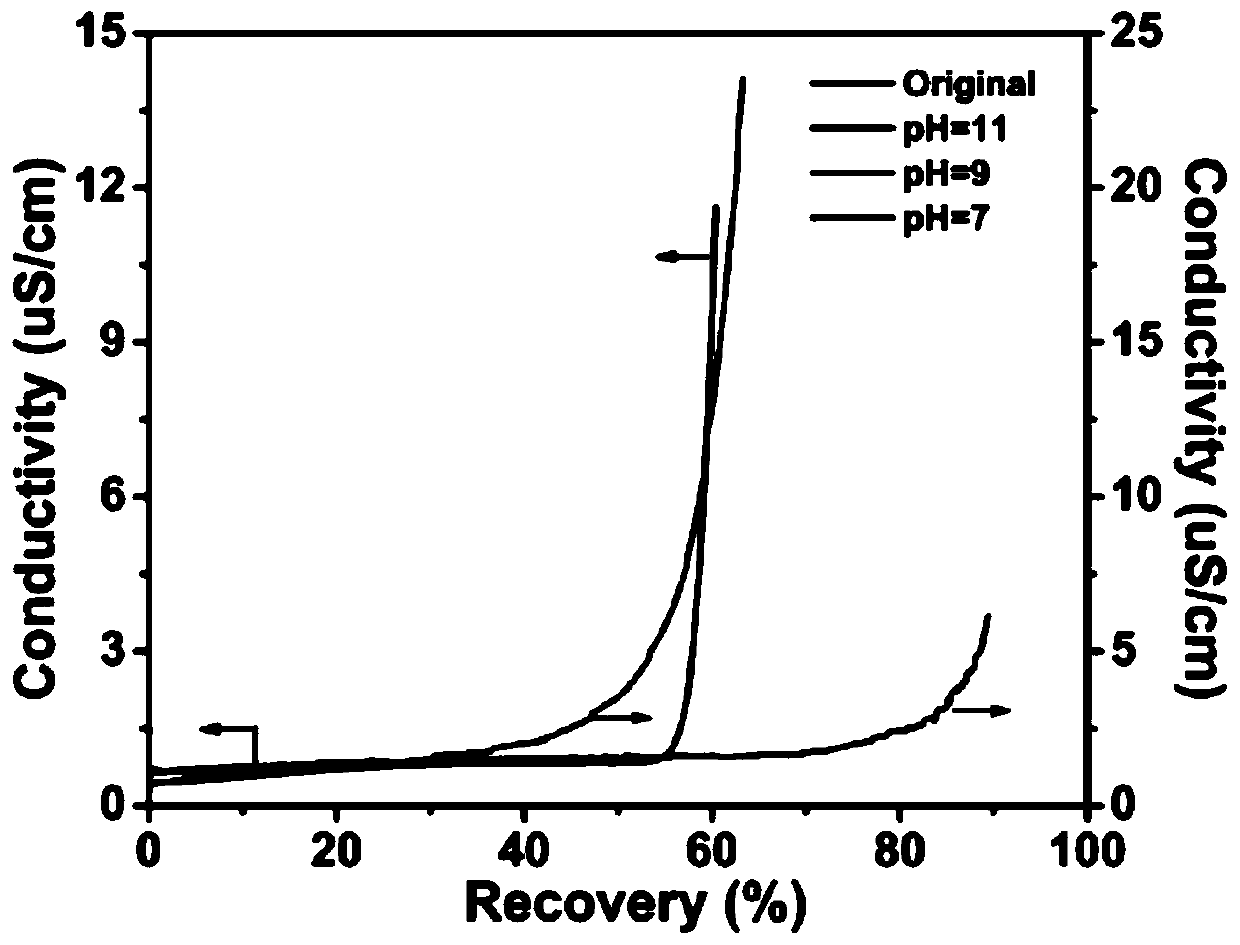

[0054] Due to its good catalytic activity, platinum is widely used as an active component of catalytic materials in the fields of petrochemical, fine chemical, organic chemical, fuel cell and exhaust gas purification. The content of platinum in the spent catalyst is much higher than that of the original ore, and the energy consumption, environmental pollution and process complexity of the recovery process are all lower than that of the original ore mining. Due to the serious shortage of platinum resources, the comprehensive recycling of secondary resources of platinum metal has become an important source. In this case, the characteristics and advantages of the present invention are clarified by taking the treatment of the waste water recovered from the actual spent catalyst platinum as an example.

[0055] The source of the exhausted catalyst platinum recovery wastewater is a precious metal resource recovery company, and the water quality is as follows Figure 4 As shown, usi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com