A green rust mixed with nano-silver particle dechlorination agent and its preparation method and application

A technology of nano-silver particles and dechlorination agent, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., to achieve the effects of simple and easy reagents, high reaction efficiency, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

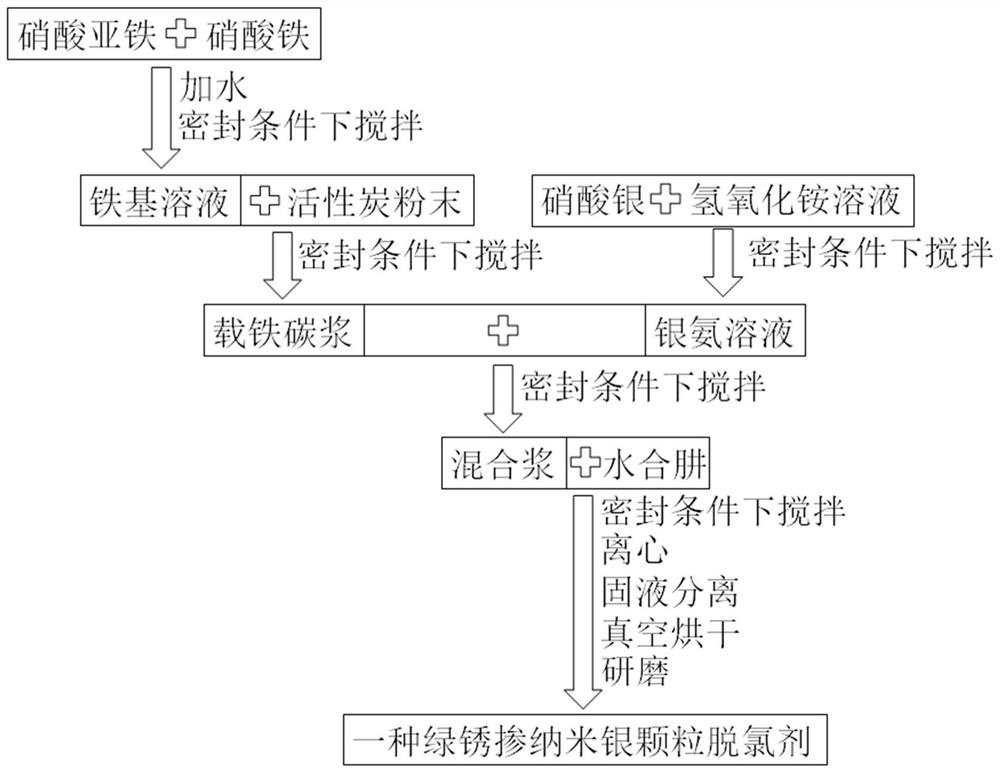

Method used

Image

Examples

Embodiment 1 2

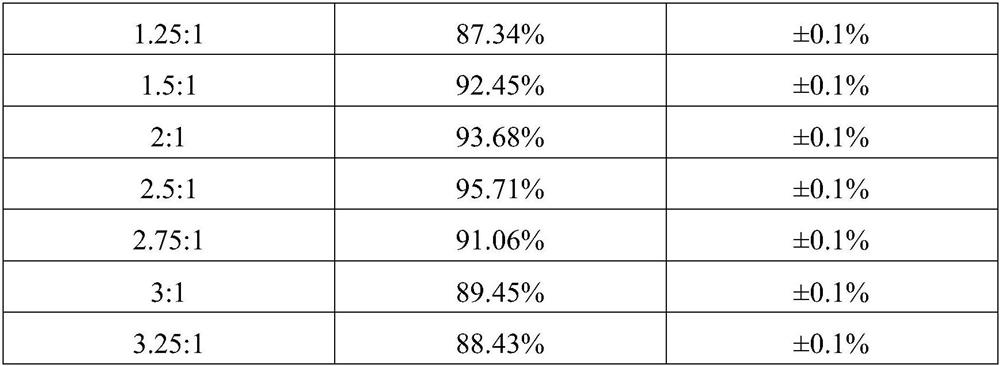

[0023] Embodiment 1 Ferrous ion and ferric ion molar ratio are on the influence of prepared dechlorination agent on 1,2,4-trichlorobenzene removal rate in water body

[0024] According to the molar ratio of ferrous ions and ferric ions 0.75:1, 1:1, 1.25:1, 1.5:1, 2:1, 2.5:1, 2.75:1, 3:1, 3.25:1 Ferric nitrate and ferrous nitrate are then mixed to obtain nine groups of mixed powders. According to the liquid-solid ratio of 1:1mL / mg, the nine groups of mixed powders of ferric nitrate and ferrous nitrate are added to water respectively, and stirred under sealed conditions until ferric nitrate and ferrous nitrate are mixed. The iron was completely dissolved, and nine groups of iron-based solutions were obtained. According to the liquid-solid ratio of 5:1mL / mg, nine groups of iron-based solutions were mixed with activated carbon powder, and stirred for 10 minutes under sealed conditions to obtain nine groups of iron-loaded carbon slurries. Weigh nine groups of silver nitrate accord...

Embodiment 2

[0031] Example 2 The effect of iron-based solution and activated carbon powder liquid-solid ratio on the prepared dechlorination agent on the removal rate of 1,2,4-trichlorobenzene in water

[0032] Weigh ferric nitrate and ferrous nitrate to obtain a mixed powder according to the molar ratio of ferrous ions and ferric ions of 2.5:1, add the mixed powder of ferric nitrate and ferrous nitrate to water according to the liquid-solid ratio of 1.5:1mL / mg, seal Stir under the conditions until the ferric nitrate and ferrous nitrate are completely dissolved to obtain an iron-based solution. According to the liquid-solid ratio 2.5: 1mL / mg, 3: 1mL / mg, 4: 1mL / mg, 5: 1mL / mg, 10: 1mL / mg, 15: 1mL / mg, 16: 1mL / mg, 17: 1mL / mg mg, 17.5:1mL / mg, mix the iron-based solution and activated carbon powder respectively, and stir for 20 minutes under sealed conditions to obtain nine groups of iron-loaded carbon slurries. Weigh silver nitrate according to the molar ratio of silver ions to ferrous nitrat...

Embodiment 3

[0038] Embodiment 3 Silver ion and ferrous ion molar ratio are on the influence of prepared dechlorination agent on 1,2,4-trichlorobenzene removal rate in water body

[0039] Weigh ferric nitrate and ferrous nitrate to obtain a mixed powder according to the molar ratio of ferrous ions and ferric ions of 2.5:1, add the mixed powder of ferric nitrate and ferrous nitrate to water according to the liquid-solid ratio of 2:1mL / mg, seal Stir under the conditions until the ferric nitrate and ferrous nitrate are completely dissolved to obtain an iron-based solution. Mix the iron-based solution and activated carbon powder according to the liquid-solid ratio of 15:1 mL / mg, and stir for 30 minutes under sealed conditions to obtain iron-loaded carbon slurry. According to the molar ratio of ferrous ions in silver ions and ferrous nitrate respectively 0.25:10, 0.3:10, 0.4:10, 0.5:10, 1:10, 1.5:10, 1.6:10, 1.7:10, 1.75: 10 Weigh the silver nitrate, then mix the silver nitrate into the ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com