A kind of dust cleaning method and filter device of bag bottom reinforced filter bag with variable inner channel

A filter device and cloth bag technology, which is applied in the field of bag bottom enhanced filter bag dust removal and filter device with variable inner channel, can solve the problem of reduced pressure rise speed of filter bag, reduced gas flow rate of dust removal, large filter area of filter bag, etc. Problems, the effect of reaching the pressure peak and increasing the pressure rising speed, improving the impact strength and impact speed, and reducing the equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

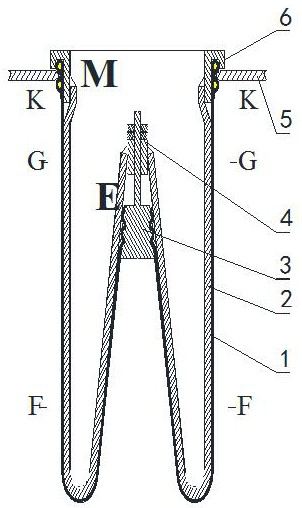

[0028] A bag bottom enhanced filter bag dust removal method with variable inner passage: take a filter bag and make the inner passage in the filter bag through which the ash cleaning airflow flows through variable, and the variable inner passage is to make the inner passage The cross-sectional area decreases along the direction from the opening of the filter bag to the bottom of the filter bag. When the cleaning airflow enters the filter bag and flows to the bottom of the filter bag, the cross-sectional area of the channel in the filter bag is continuously reduced so that the filter bag continues to compress the cleaning airflow and improve The impact pressure and impact velocity of the dust removal airflow strengthen the dust removal at the bottom of the filter bag, so that the dust particles bonded to the bottom of the filter bag can be removed.

[0029] In this embodiment, the filter bag adopts a W-shaped filter bag with a W-shaped axial interface, and uses a W-shaped filt...

Embodiment 2

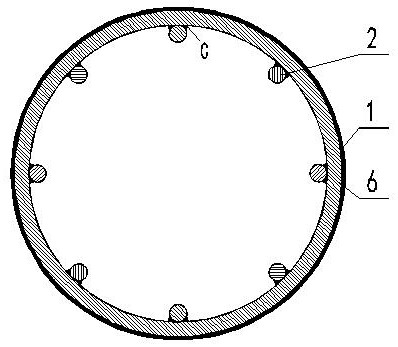

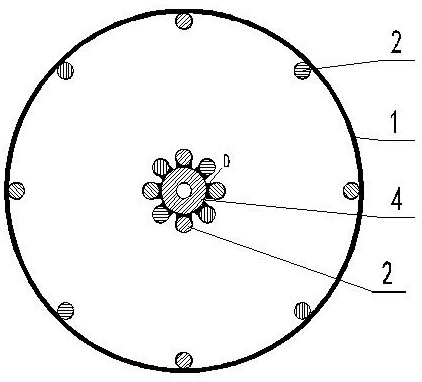

[0031] A filter device for a bag bottom enhanced filter bag cleaning method with variable internal channels, comprising a cage frame and a frame pressing sleeve 6, a cloth bag is set outside the cage frame and the cloth bag 1 is bonded to the cage frame , the cage skeleton includes cohesive connectors 4 and at least three V-shaped steel gardens 2, one end of the V-shaped steel gardens 2 is fixed to the cohesive connectors 4 and enclosed to form a conical inward concave cavity, refer to Figure 5 Specifically, one end of the V-shaped steel garden 2 can be welded to the D of the cohesive connector 4, and the other end of the V-shaped steel garden 2 can be folded in the skeleton compression sleeve 6, referring to Image 6 Specifically, the other end of the V-shaped steel garden 2 can be welded to the C place of the skeleton pressure sleeve 6, and a detachable cloth bag tensioning slider 3 is provided in the conical inwardly recessed cavity, and one end of the cloth bag 1 Put it o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com