Method for heating inlet water of boiler deaerator

A heating method and deaerator technology, which is applied in the field of boilers, can solve the problems of poor deoxygenation effect of boilers of small steam turbine units and affect the power of steam turbines, etc., and achieve the effects of reducing steam extraction of steam turbines, improving economic benefits, and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

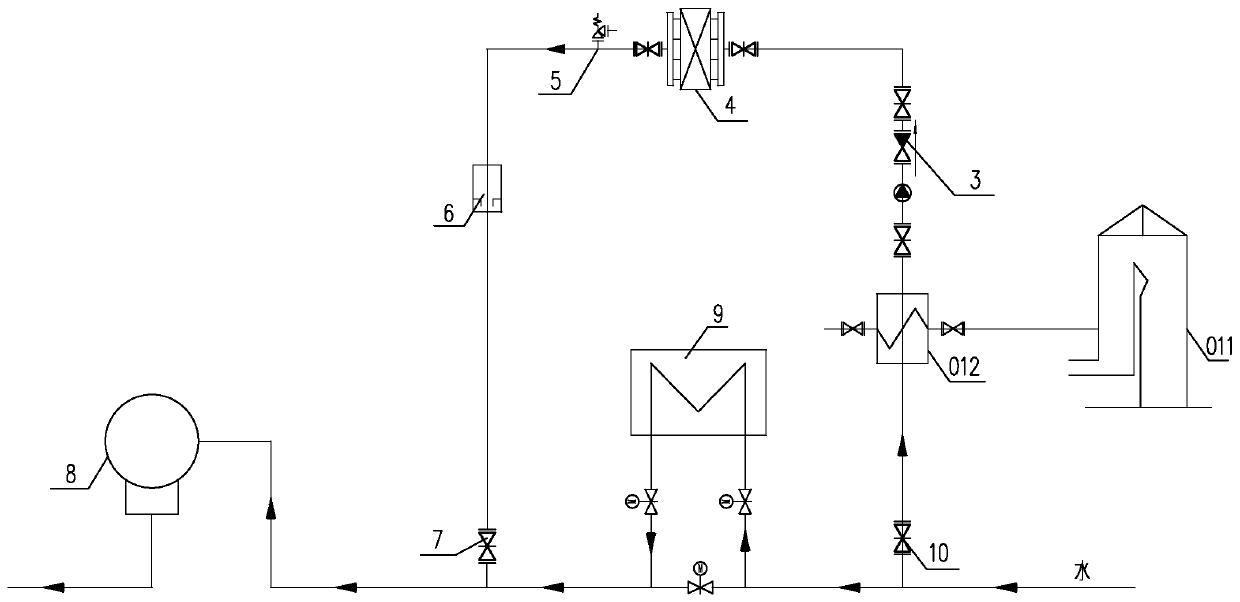

[0046] refer to figure 1 , a back-pressure turbogenerator set based on boiler sewage composite heating boiler deaerator inlet water heating system, mainly including the boiler body, boiler sewage waste heat supplementary heat heater and heat pipe boiler flue gas waste heat heat exchange device. The steam volume of the boiler is 480t / h, the temperature of the boiler sewage is generally about 150°C, the pressure is about 0.5MPa, and the size of the heat exchanger is 900mm×2200mm. The size of boiler flue gas waste heat heat exchanger is 4000mm×5000mm×3200mm, and the heat exchanger is installed in the vertical flue behind the dust collector.

Embodiment 2

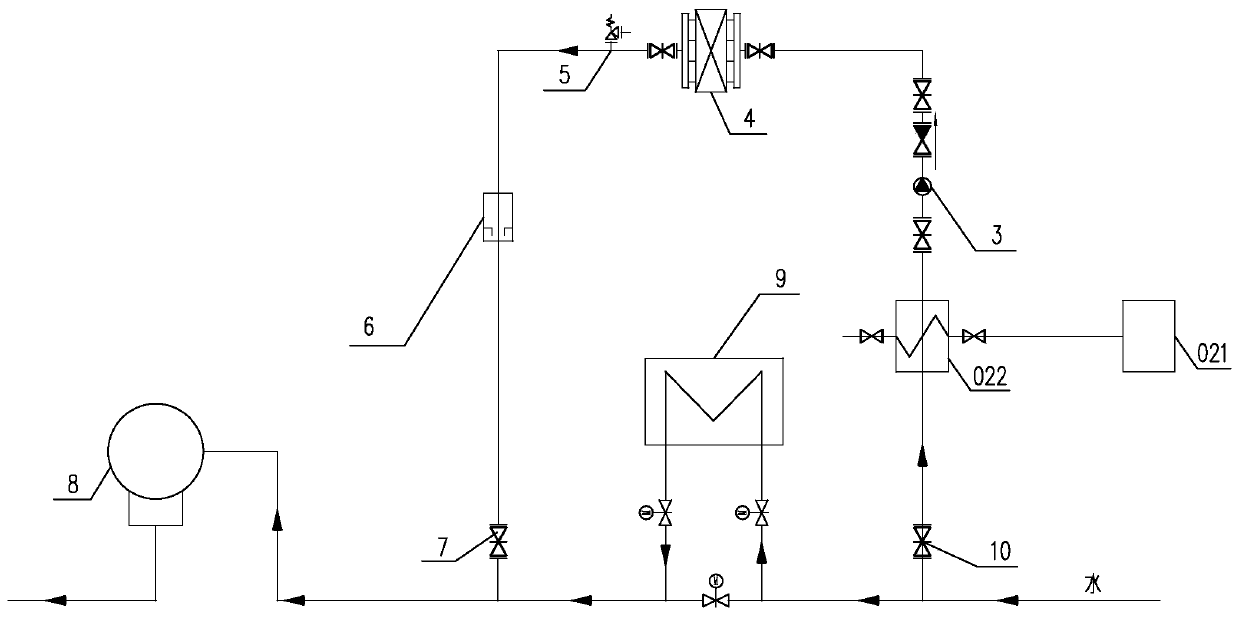

[0048] refer to figure 2 The invention discloses a boiler deaerator inlet water heating system based on steam heating and supplementary heat of a back pressure turbogenerator set, which mainly includes a low-pressure steam source, a low-pressure steam supplementary heat heater and a boiler flue gas waste heat exchanger. The steam capacity of the boiler is 240t / h, and the steam waste heat supplementary heater is a shell-and-tube heat exchanger with a steam temperature of about 150°C. The size of the heat exchanger is 450mm×2250mm, and it is installed on a 12m platform in the steam turbine workshop. The boiler flue gas waste heat exchanger is installed in the tail flue of the outlet of the dust collector, and the installation size is 3600mm×4500mm×3500mm.

Embodiment 3

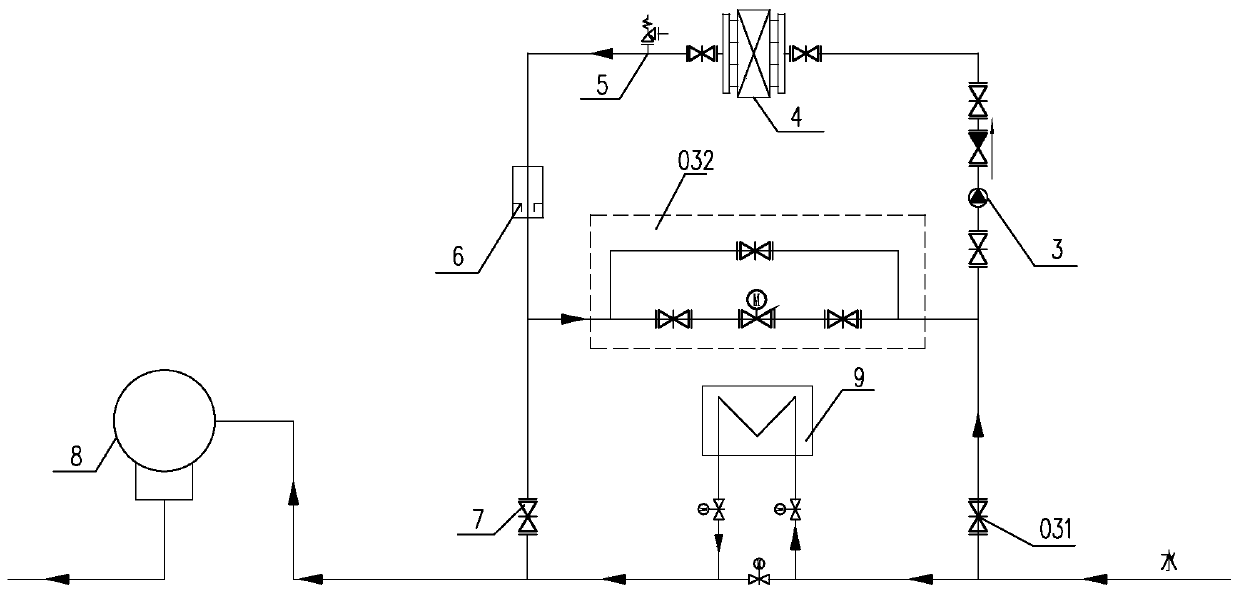

[0050] refer to image 3 , a back pressure turbogenerator set based on waste water recirculation boiler deaerator inlet water heating system, mainly includes: recirculation regulating valve group, pipeline booster pump group and boiler flue gas waste heat exchanger. The recirculation regulating valve group is the key to improving the wall temperature and maintaining the system. A recirculation loop is added, and the recirculation regulating valve group divides part of the water from the B-way water flowing out of the boiler flue gas waste heat heat exchanger as the C-way water. , and then the recirculation regulating valve group returns the C-way water into the boiler flue gas waste heat heat exchanger to complete the recirculation of waste water, and can adjust the recirculation water volume to adjust the wall temperature. In order to improve the heat exchange tube wall temperature in the flue and maintain the system, the recirculation regulating valve group is composed of on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com