A kind of hot-rolled hot-formed steel and its preparation method

A hot forming steel and hot forming technology, applied in the field of high-strength steel for automobiles, can solve the problems of high cost, long production process and high energy consumption, and achieve the effect of reducing the opportunity of introducing hydrogen, reducing the cost of hot stamping, and optimizing the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] According to a typical embodiment of the present invention, a method for preparing hot-rolled hot-formed steel is also provided, including:

[0045] Obtain hot-rolled sheet;

[0046] performing hot forming and quenching simulation on the hot-rolled sheet to obtain hot-rolled hot-formed steel;

[0047] In the hot forming quenching simulation, the hot-rolled sheet is heated to 800°C-900°C and held for 2min-8min, and the quenching cooling rate is ≥40°C / s.

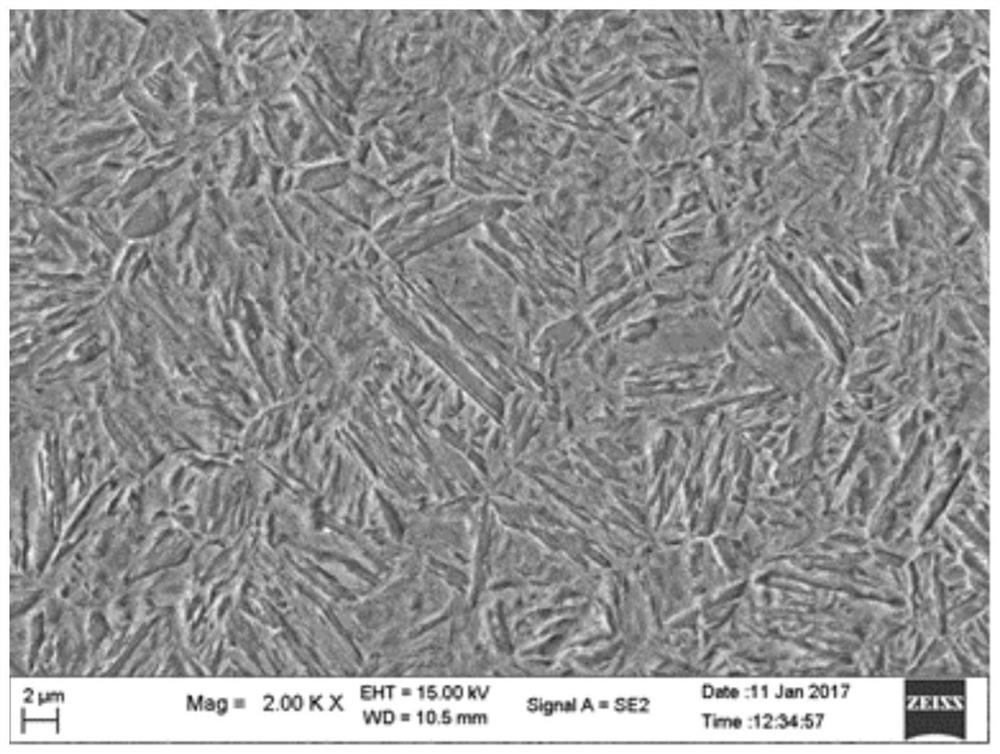

[0048] At present, the commonly used holding temperature for hot-rolled hot-forming steel is 930°C. The relatively low holding temperature of the present invention can avoid the growth of grains on the one hand, and save energy on the other hand. The cooling rate ≥ 40°C / s ensures that the final product with horsepower Hot-rolled hot-formed steel with a microstructure.

[0049] As some preferred embodiments, the thickness of the hot-rolled sheet is 1.2mm-3.0mm.

[0050] As some preferred implementations, the obtaining o...

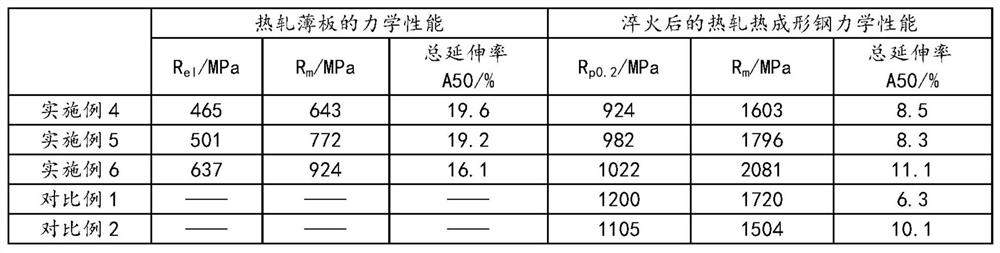

Embodiment 4

[0064] This embodiment provides a method for preparing hot-rolled thermoformed steel, which is used to prepare hot-rolled thermoformed steel containing the chemical composition in Example 1, including:

[0065] S1: Obtain a slab with the chemical composition in Example 1;

[0066] S2: heating and keeping the cast slab sequentially, primary descaling, rough rolling, secondary descaling, finish rolling, laminar cooling, coiling and leveling to obtain a hot-rolled sheet;

[0067] In the heating and heat preservation, the billet is heated to 1220°C and held for 1 hour; the start rolling temperature of the rough rolling is 1140°C, and the total reduction rate of the rough rolling is 75%; the entrance temperature of the finishing rolling is 1040°C. ℃, the finish rolling temperature of the finishing rolling is 880 ℃; the coiling temperature is 650 ℃; the thickness of the hot-rolled sheet is 1.5mm;

[0068] S3: The hot-rolled sheet is subjected to a hot-forming quenching simulation t...

Embodiment 5

[0070] This embodiment provides a method for preparing hot-rolled thermoformed steel, which is used to prepare hot-rolled thermoformed steel containing the chemical composition in Example 2, including:

[0071] S1: Obtain a slab with the chemical composition in Example 2;

[0072] S2: heating and keeping the cast slab sequentially, primary descaling, rough rolling, secondary descaling, finish rolling, laminar cooling, coiling and leveling to obtain a hot-rolled sheet;

[0073] In the heating and heat preservation, the billet is heated to 1220°C and held for 1.5h; the start rolling temperature of the rough rolling is 1120°C, and the total reduction rate of the rough rolling is 73%; the entrance temperature of the finish rolling is 1035°C, the finish rolling temperature is 885°C; the coiling temperature is 630°C; the thickness of the hot-rolled sheet is 2.0mm;

[0074] S3: The hot-rolled thin plate is subjected to a hot-forming quenching simulation to obtain a hot-rolled hot-fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com