A thermoformed member with a tensile strength of 1800mpa or more and excellent cold bending performance and its preparation method

A technology of tensile strength and cold bending performance, applied in the field of thermoforming components and their preparation, can solve the problems of inability to effectively absorb energy, adverse occupant safety, increased strength, etc., and achieve the effect of improving delayed cracking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

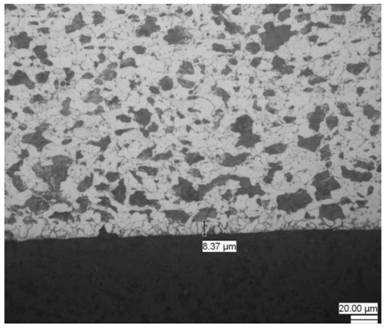

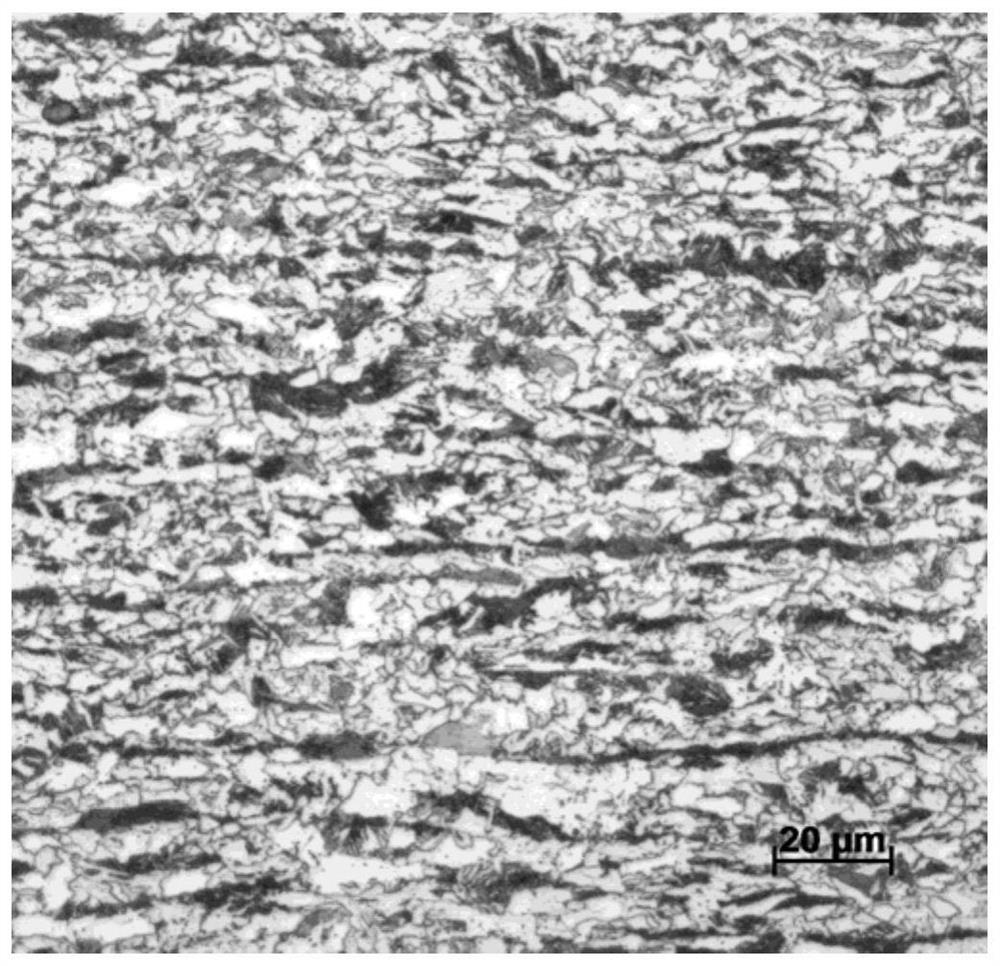

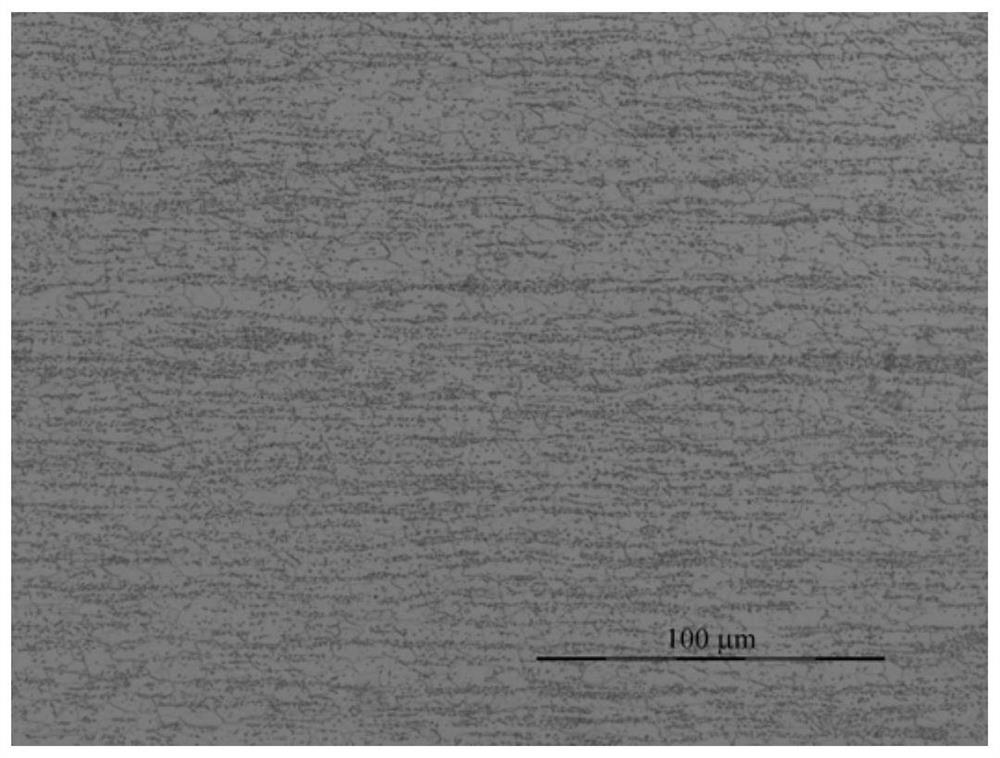

[0039] The present invention will be described in detail below in conjunction with examples.

[0040]Table 1 shows the chemical composition and weight percentage of the thermoformed components with excellent cold-bending properties having a tensile strength above 1800 MPa in each embodiment.

[0041] Table 1 Chemical composition (wt%) of steel plate and corresponding mechanical properties after hot forming

[0042]

[0043] The hot-formed components with excellent cold-bending properties with a tensile strength above 1800 MPa in each embodiment are prepared by the following steps: smelting, continuous casting, hot rolling, pickling, annealing, edge trimming, and thermoforming.

[0044] Among them, the preparation process parameters and properties before thermoforming are shown in Tables 2 and 3, respectively, and the thermoforming process parameters and properties are shown in Tables 4 and 5, respectively.

[0045] Table 2 Preparation process parameters before thermoformin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com