Blast furnace gas hydrolysis and dry-process fine desulfurization treatment system and method

A blast furnace gas and treatment system technology, which is applied in gas dust removal, combustible gas purification, gas pollutant removal, etc., can solve the problem that the total sulfur content of the export gas cannot meet the ultra-low emission, desulfurization process wastewater, dry adsorption saturation analysis Difficulty regenerating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

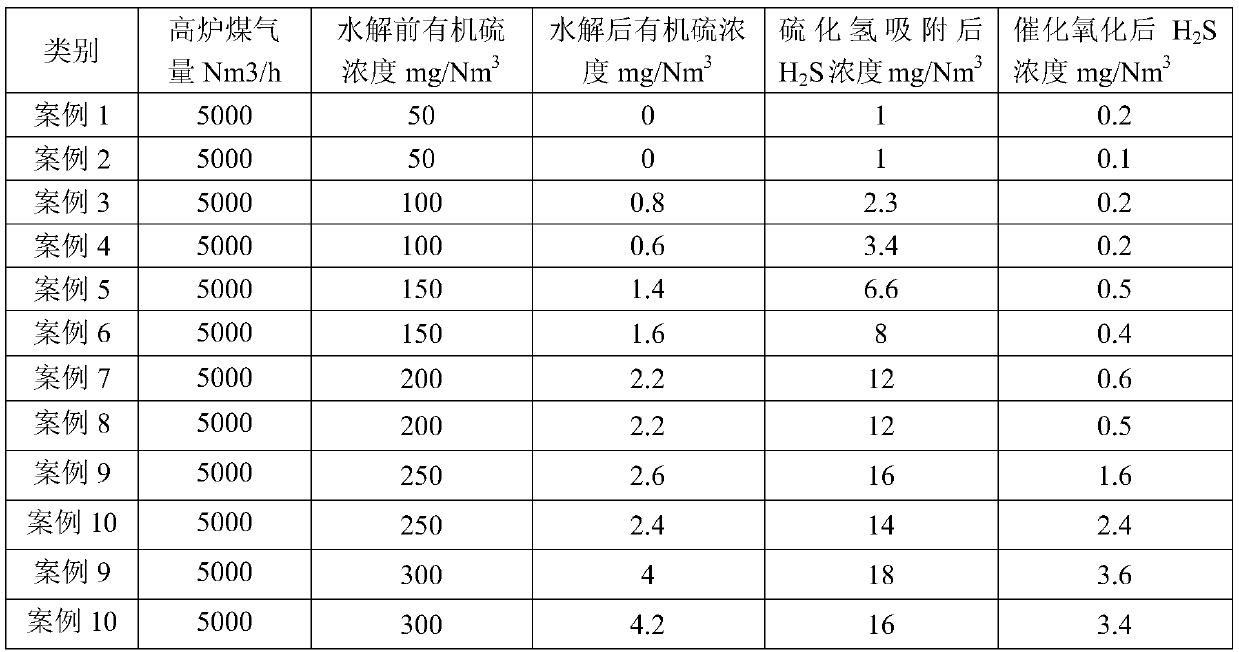

Examples

Embodiment Construction

[0027] In order to better reflect the superiority of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Such as figure 1 As shown, the system of the present invention includes a gas booster fan 1, a gas cooling heat exchanger 2, a cooling water tower device 3, a cooling circulating water pump 4, a catalytic hydrolysis tower 5, a hydrolysis catalyst 6, a gas reheater 7 at the front end of an adsorption tower, and a vulcanization Hydrogen adsorption tower 8, adsorption catalyst 9 in the adsorption tower, gas bypass valve system 10 at the rear end of the adsorption tower, gas reheater 11 at the rear end of the adsorption tower, catalytic oxidation tower 12, and adsorption catalyst 13 in the oxidation tower.

[0029] The gas produced by the blast furnace is coarsely dedusted by the gravity dust collector from the top, and then finely dedusted by the bag filter. The raw gas is directly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com