Segmented water inlet multistage anoxic/aerobic biological denitrification treatment method for sewage at low temperature

A segmented water and sewage biological technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, multi-stage water treatment, etc., can solve the problem of low denitrification utilization efficiency of biodegradable organic matter, and achieve high biological The effect of nitrification and denitrification denitrification capacity, improvement of utilization efficiency and optimization of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

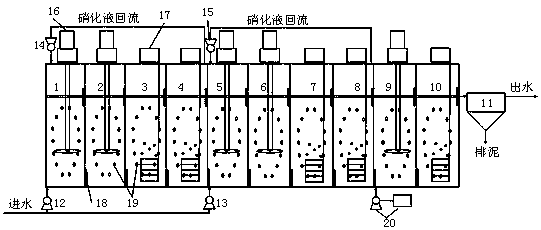

[0034] In the present invention, the three-stage anoxic / aerobic combined reaction zone biofilm is used to carry out efficient denitrification treatment of sewage. The system used is as follows: figure 1 As shown, it consists of a three-stage A / O reaction unit and a muddy water clarification separation unit 11 connected in sequence.

[0035] The first-stage A / O reaction unit consists of A1 anoxic raw water carbon source denitrification functional reactor 1, A2 anoxic raw water carbon source denitrification functional reactor 2, O3 aerobic organic matter degradation functional reactor 3 and O4 good The oxygen nitrification functionalized reactor consists of 4 four biofilm reactors. A first-stage nitrifying liquid reflux pump 14 is set in the outlet well (or pipe channel) behind the outflow screen at the end of the first-stage A / O reaction unit to return the O4 outflow mixed liquid of the aerobic nitrification functional reactor to A1 In the anoxic raw water carbon source denitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com