Metal product machining and polishing device

A technology of metal products and grinding mechanisms, applied in metal processing equipment, grinding drive devices, manufacturing tools, etc., can solve the problems of low grinding processing efficiency and large output of manual labor, so as to reduce the output of manual labor and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

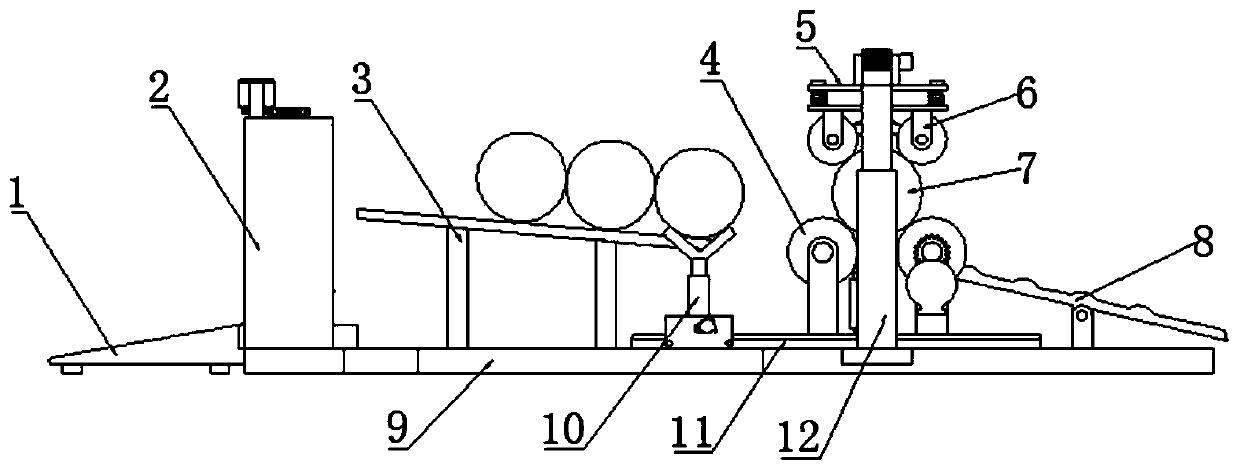

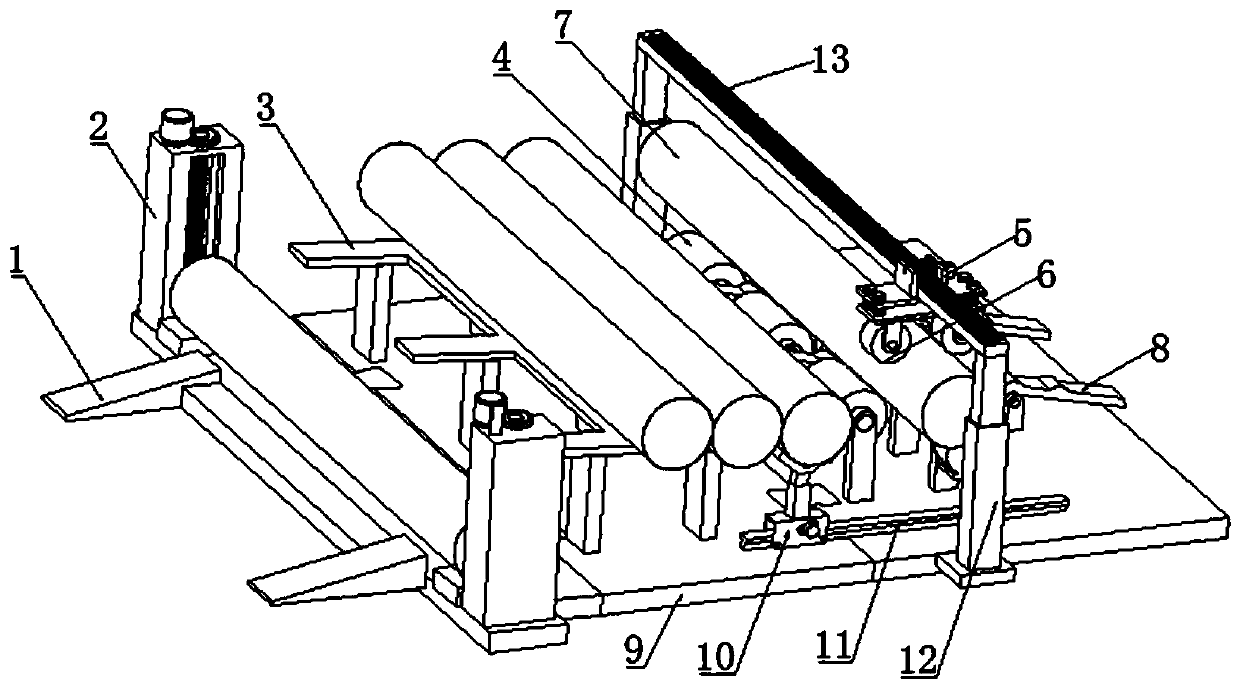

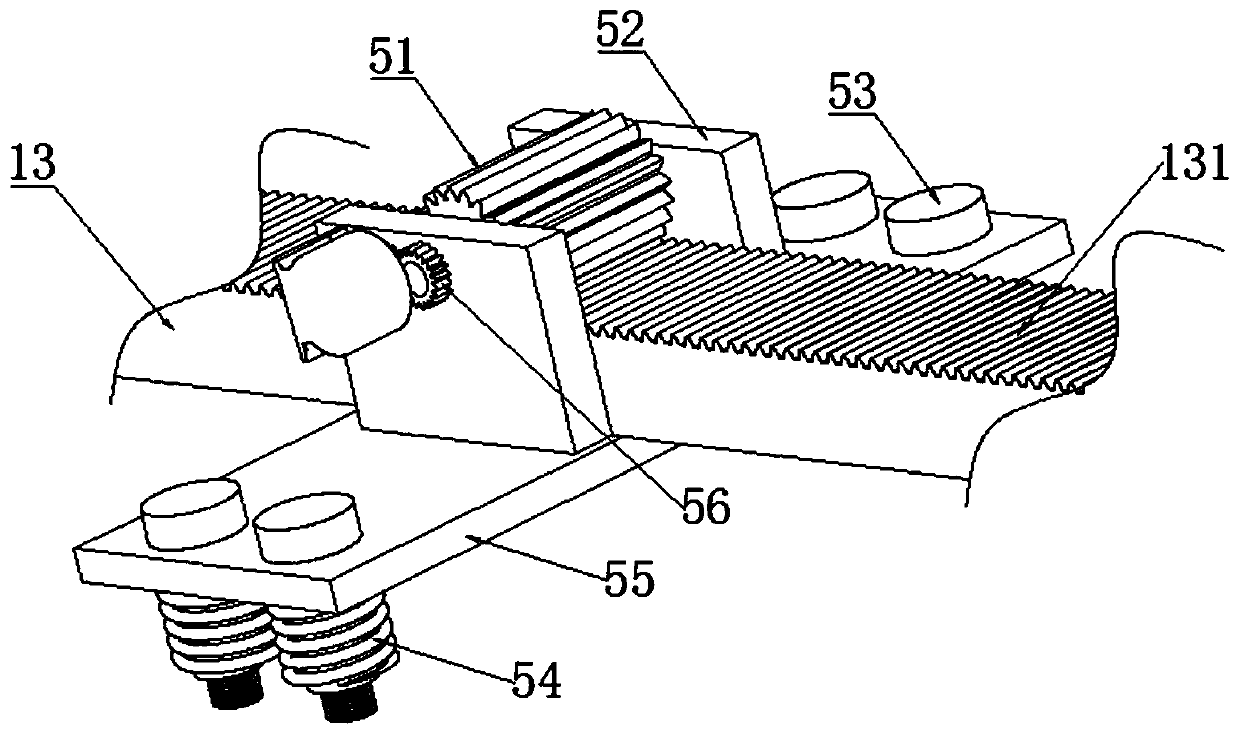

[0034] Example 1, please refer to figure 1 and figure 2 As shown, a metal product processing and polishing device includes a base plate 9, a material guide mechanism 1 for feeding guide is provided at the left end of the base plate 9, and a lifting device for lifting the workpiece 7 is provided on the front and rear sides of the upper surface of the base plate 9 near the left end. Mechanism 2, the right side of lifting mechanism 2 is provided with the placement frame 3 that places workpiece 7, and placement frame 3 is used for stacking the workpiece 7 to be processed, and placement frame 3 is provided with inclination to the lower right, and is positioned at the right side of placement frame 3 and is provided with A plurality of supporting rollers 4 that roll and support the workpiece 7 are provided with vertical second elevating rods 12 at the front and rear sides of the supporting rollers 4, and one of electric elevating rods, hydraulic cylinders or cylinders is selected, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com