Optical laminate

An optical layer and combination technology, applied in optics, optical elements, filters, etc., can solve problems such as deterioration of the visual appreciation characteristics of polarizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

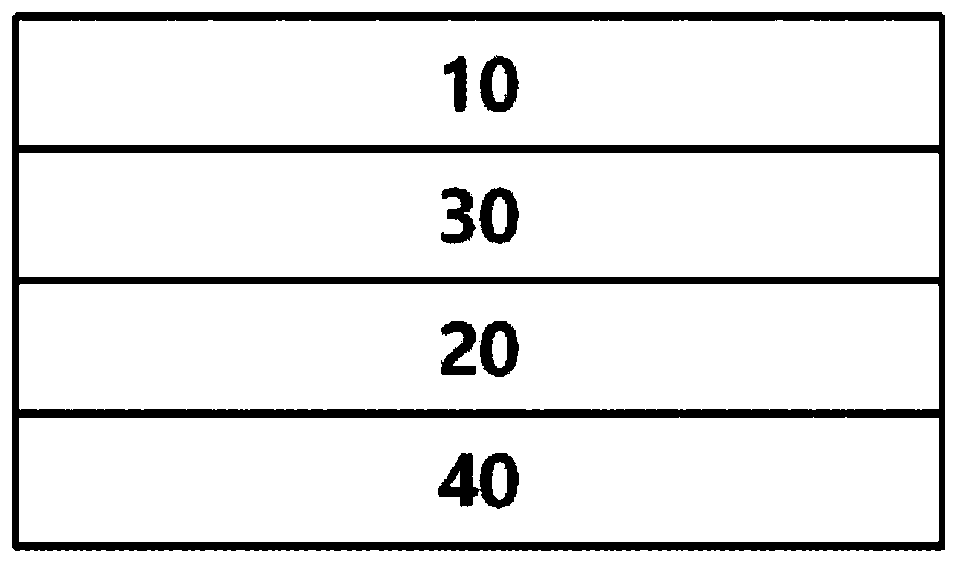

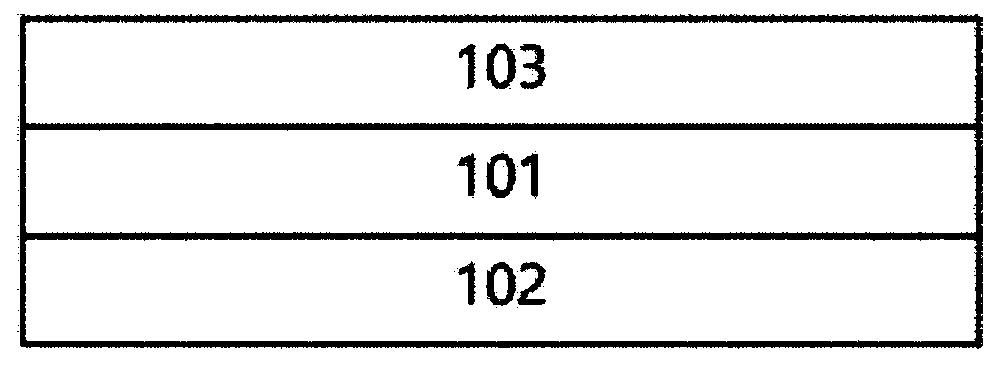

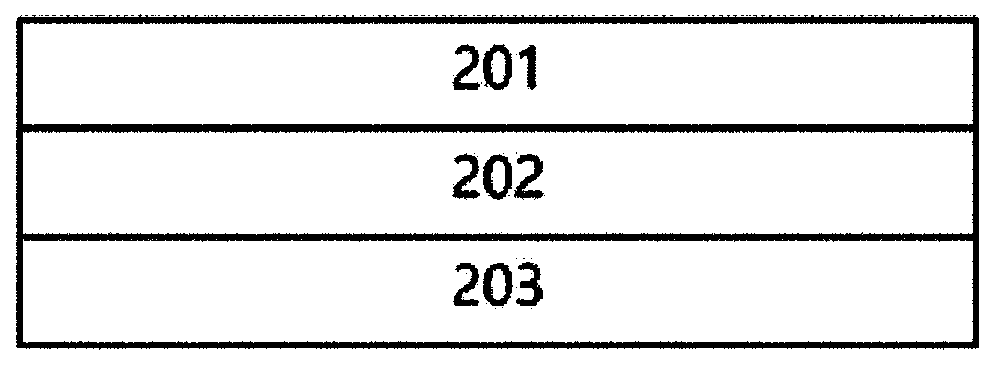

Method used

Image

Examples

Embodiment Construction

[0176] Hereinafter, the present application is described with reference to examples. However, the scope of rights of the present application is not limited by the following examples.

[0177] 1. Evaluation of optical properties of polarizing plates

[0178] The polarizing plates prepared in Examples and Comparative Examples were cut into a size of 25 mm×25 mm (width×length) to produce samples.

[0179] The blocking performance against ultraviolet rays including a blue region was evaluated by measuring the transmittance of the polarizing plate using an ultraviolet-visible spectrometer (V-7100, JASCO). Here, when the total light incident amount is set to 100, the transmittance represents the amount of light transmitted through the polarizing plate as a ratio of %.

[0180] 2. Durability evaluation under reliability conditions

[0181] Specimens prepared by cutting the polarizing plates prepared in Examples and Comparative Examples into a size of 90 mm×170 mm (width×length) we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com