Inserting type multi-level mixing DPF combustor

A burner and DPF technology, applied in the direction of machines/engines, noise reduction devices, engine components, etc., can solve the problems of high residual oxygen content, inconvenient installation and layout, high cost, etc., and achieve extended time, increased mixing space, and complete combustion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

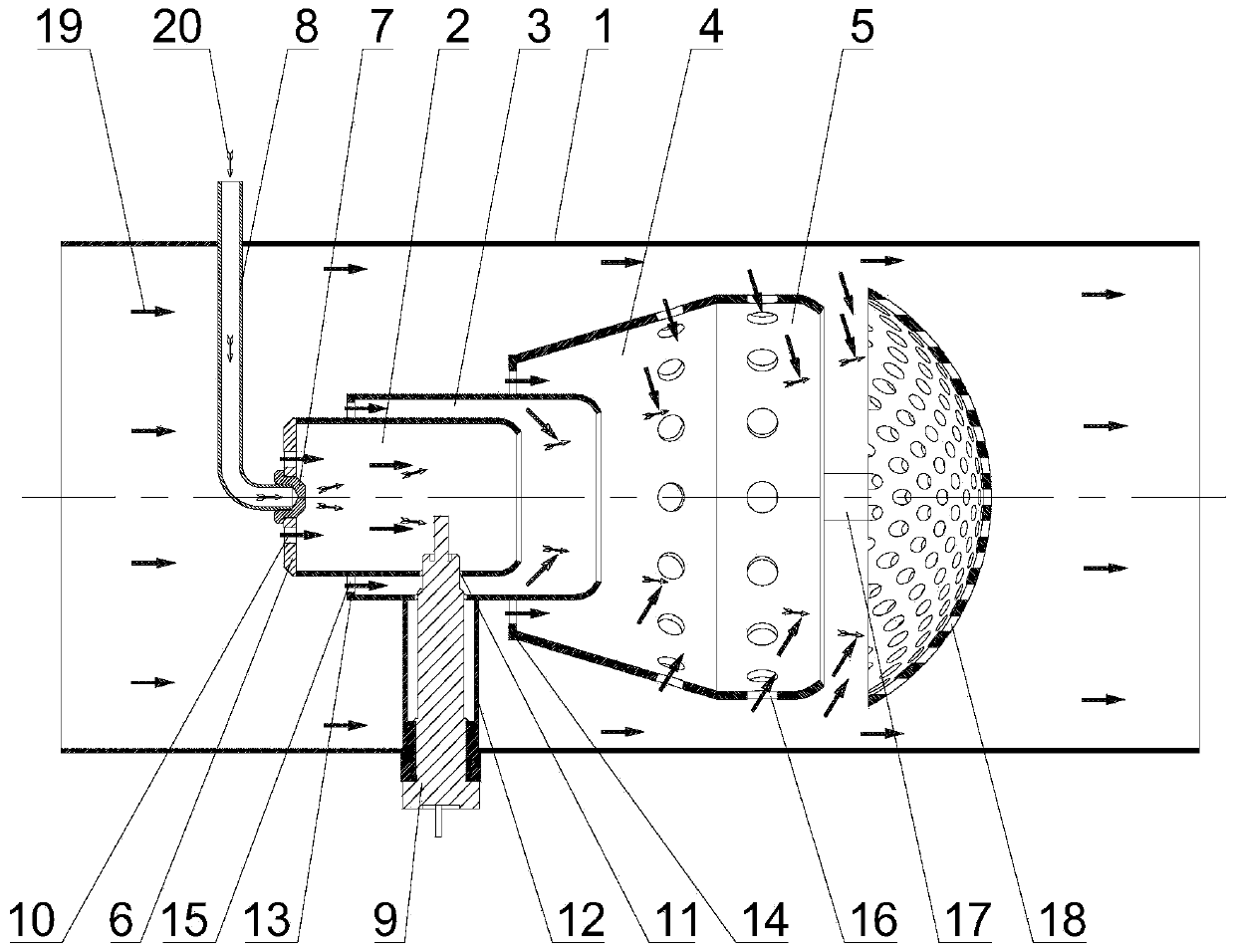

[0023] see figure 1 As shown, this embodiment provides a plug-in multi-stage mixing DPF burner, which includes a burner outer cylinder 1 and a multi-stage combustion chamber located in the burner outer cylinder 1 .

[0024] The front end of the combustor outer cylinder 1 is connected to the exhaust pipe of the diesel engine, and the rear end is connected to the DPF catcher.

[0025] It should be noted that since the residual oxygen content in the diesel engine exhaust 19 is lower than that of fresh air, the original primary mixed combustion is difficult to achieve complete combustion, the combustion efficiency is low, and the combustion is unstable. Therefore, a multi-stage combustion chamber is used to realize the exhaust 19 Mix with fuel more than 20 times to help complete combustion. It is advisable that the number of stages of the combustion chamber should be no less than 2. In the present embodiment, the multistage combustion chamber includes an inner combustion chamber ...

Embodiment 2

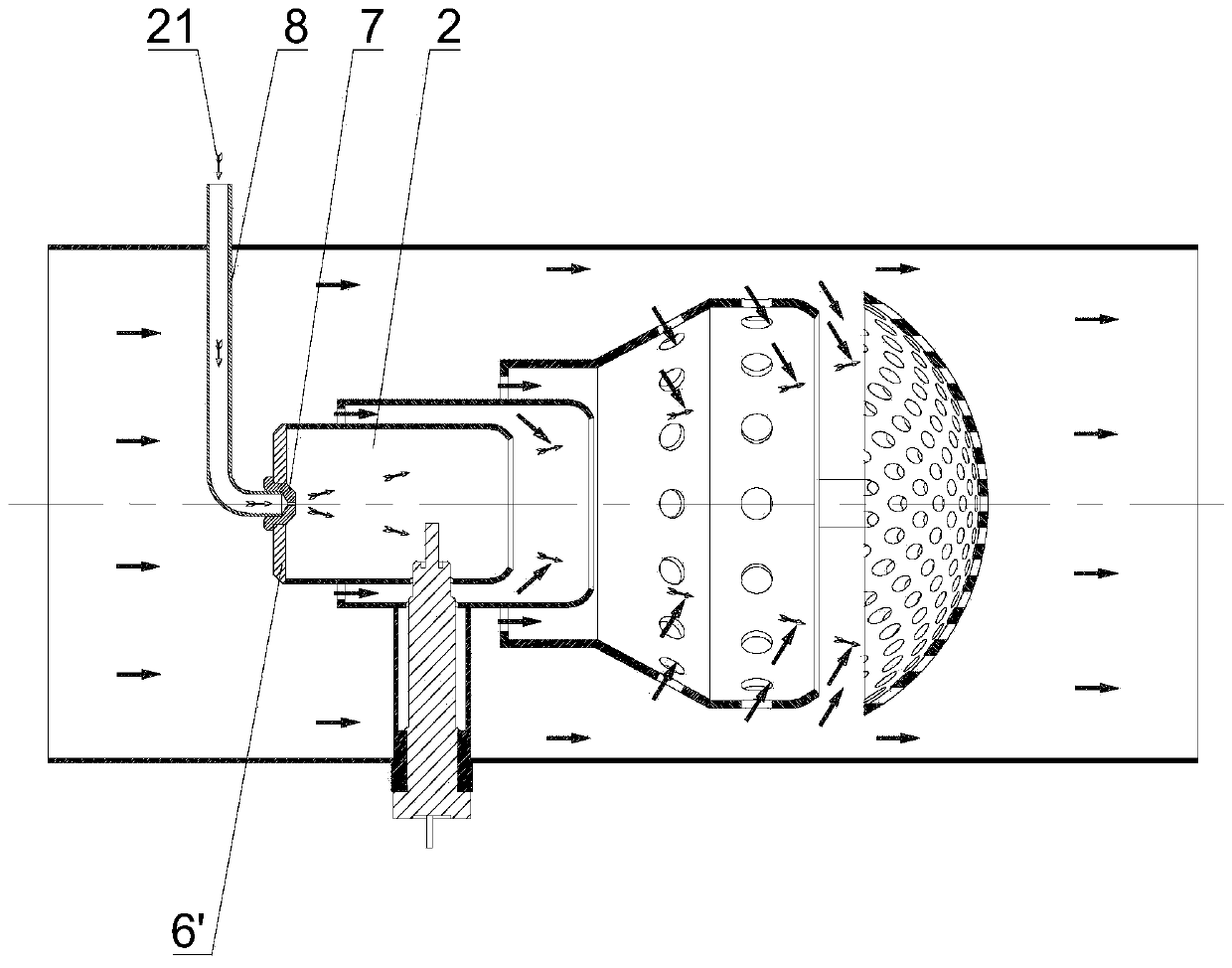

[0033] see figure 2 As shown, this embodiment provides a plug-in multi-stage hybrid DPF burner on the basis of Embodiment 1. The difference between it and Embodiment 1 is that the fuel 20 does not use high-pressure direct injection, but uses compressed air auxiliary injection. Therefore, what is injected into the internal combustion chamber 2 from the injection pipe 8 and the nozzle 7 is a mixture 21 of fuel 20 and compressed air, and the compressed air is fresh air, which can be used as a combustion-supporting gas. However, the flow rate of the compressed air is very small, which can only meet the combustion needs of a small part of the fuel 20, and can only be used as a combustion support for the internal combustion chamber 2, so the air intake hole on the first end cover 6' can be reduced or even eliminated.

[0034] The advantage of this structure is that: due to the use of compressed air to assist the injection of the fuel 20, the requirements on the fuel pump are greatl...

Embodiment 3

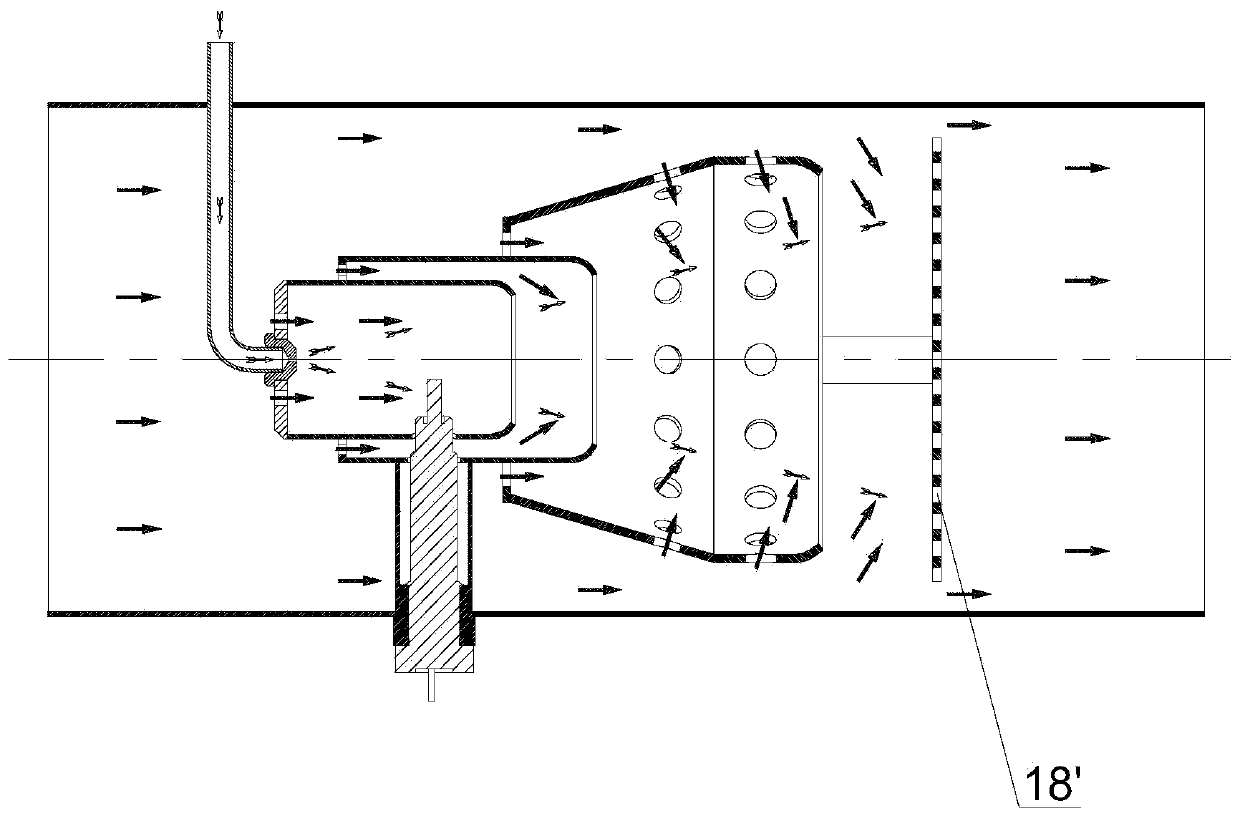

[0036] see image 3 As shown, this embodiment provides a plug-in multi-stage hybrid DPF burner on the basis of Embodiment 1 or 2. The difference is that the flame arresting net 18' adopts a flat shape, thus reducing the difficulty of the process and facilitating production. Affect the basic function of blocking flame.

[0037] In summary, the plug-in multi-stage hybrid DPF burner uses the remaining oxygen in the exhaust of the diesel engine to mix and burn the fuel, cancels the blower, and uses a multi-stage combustion chamber to make the exhaust gas and fuel form multiple mixtures, increasing the ratio of the two. The mixing space prolongs the time of mixed combustion, so that the fuel is fully mixed with the remaining oxygen in the exhaust gas, improves the combustion efficiency, achieves complete combustion, and effectively increases the temperature of the exhaust gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com