Mud separator for air shaft cast-in-situ bored pile

A technology for drilling cast-in-place piles and mud separation, which is used in earth-moving drilling, sludge treatment, wellbore flushing, etc. Small footprint, convenient construction, and the effect of promoting agitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

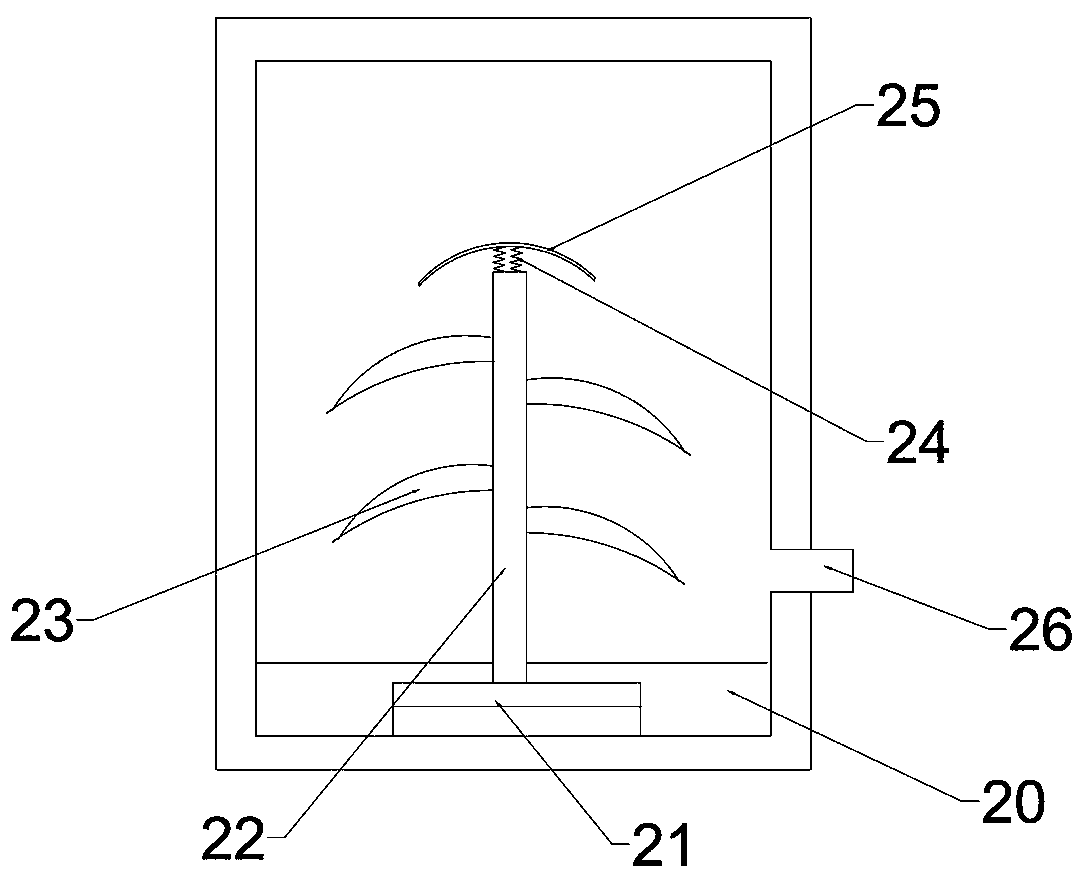

[0027] Such as Figure 1-2 As shown in the figure, a mud separator for bored piles of wind shafts includes a transmission mechanism and a mud separation device arranged above the transmission mechanism.

[0028] The transmission mechanism includes a transmission support plate and a crawler mechanism 1 arranged on both sides of the transmission support plate; the crawler mechanism 1 includes a drive wheel 18 arranged at one end of the transmission support frame 17 and connected with the main shaft of the drive motor and The driven wheel is arranged inside the transmission support frame 17, the tension wheel 27 is arranged at the other end of the transmission support frame 17, and the caterpillar belt 19 surrounds the drive wheel 18, the driven wheel and the tension wheel outside.

[0029] The mud separation device includes a coarse slurry tank 6, a vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com