Drying device and asphalt station

A drying device and spraying device technology, applied in the field of asphalt plant, can solve the problems of high cost of natural gas, large oxygen excess coefficient, huge fuel consumption, etc., and achieve the effect of reducing emissions and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

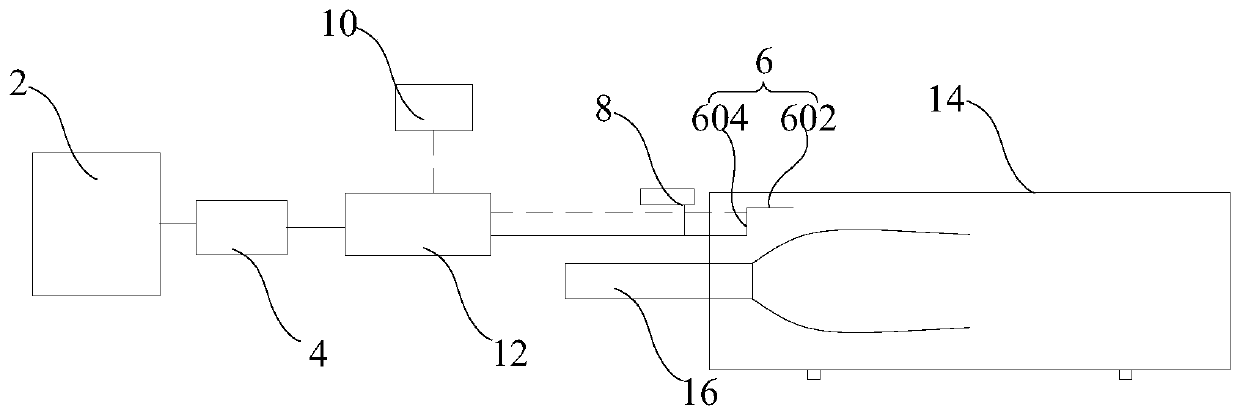

[0042] Such as Figure 1 to Figure 3 As shown, an embodiment of the present invention provides a drying device, including: a reducing agent storage tank 2 , a pump 4 , a drying drum 14 , a burner 16 and a spraying device 6 .

[0043] Wherein, the input end of the pump 4 is connected to the reductant storage tank 2; the burner 16 is arranged in the drying drum 14; the spray device 6 is connected to the output end of the pump 4 and is arranged in the drying drum 14 .

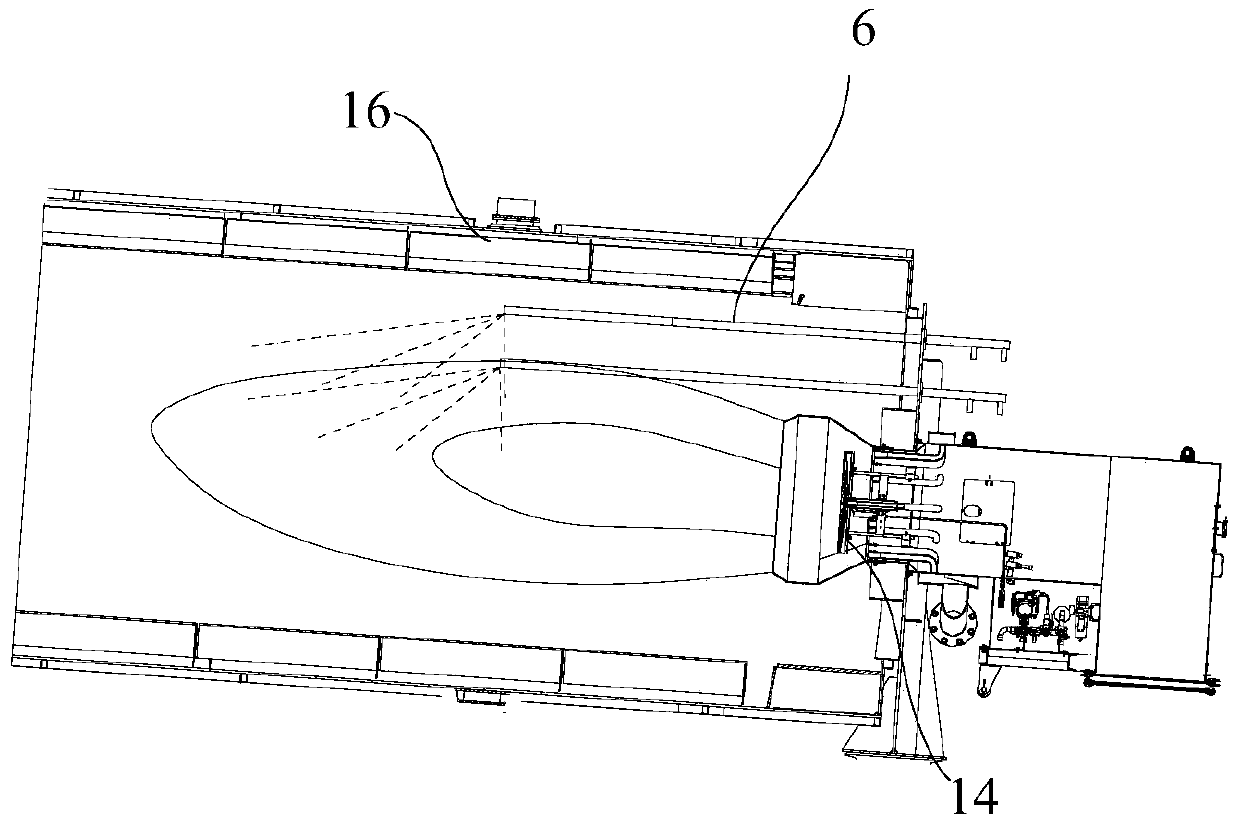

[0044] Such as figure 2 shown, where figure 2 The dotted line in the middle represents the reducing agent sprayed out by the spraying device 6, and the elliptical curve represents the flame produced by the combustion of the burner 16. In the drying device provided by the present invention, during use, the burner 16 bakes the cold material by burning heavy oil. During this process, turn on the pump 4, the pump 4 sends the reductant pump 4 in the reductant storage tank 2 to the spray device 6, the spray device ...

Embodiment 2

[0048] Such as Figure 1 to Figure 3 As shown, an embodiment of the present invention provides a drying device, including: a reducing agent storage tank 2 , a pump 4 , a drying drum 14 , a burner 16 and a spraying device 6 .

[0049] Wherein, the input end of the pump 4 is connected to the reductant storage tank 2; the burner 16 is arranged in the drying drum 14; the spray device 6 is connected to the output end of the pump 4 and is arranged in the drying drum 14 .

[0050] Such as figure 1 As shown, further, the drying device further includes: a driving device 8 connected to the spraying device 6 and adapted to drive the spraying device 6 to move along the axial direction of the drying drum 14 .

[0051] In this embodiment, the driving device 8 can drive the spraying device 6 to move. On the one hand, it can adjust the position where the spraying device 6 sprays the reducing agent, so that the reducing agent can better contact with the exhaust gas generated by the combustio...

Embodiment 3

[0053] Such as Figure 1 to Figure 3 As shown, an embodiment of the present invention provides a drying device, including: a reducing agent storage tank 2 , a pump 4 , a drying drum 14 , a burner 16 and a spraying device 6 .

[0054] Wherein, the input end of the pump 4 is connected to the reductant storage tank 2; the burner 16 is arranged in the drying drum 14; the spray device 6 is connected to the output end of the pump 4 and is arranged in the drying drum 14 .

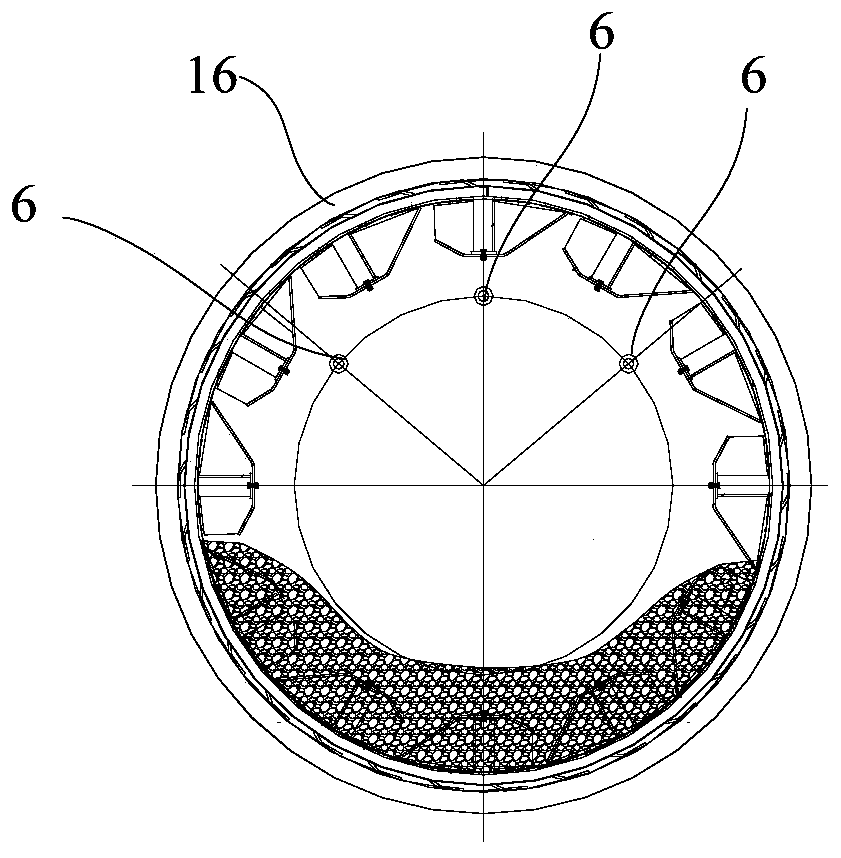

[0055] Such as figure 1 As shown, further, the spraying device 6 includes: a spray gun 602, which is connected to the output end of the pump 4; a bending part 604, which is bent in a direction away from the burner 16, and the spray gun 602 is connected to the bending part 604 is one end far away from the burner 16 , and the driving device 8 is connected to the bending part 604 .

[0056] In this technical solution, the composition of the spraying device 6 is further provided. The spraying device 6 includes a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com