Light medium- and low-frequency sound absorption material and preparation method thereof

A sound-absorbing material and low-frequency technology, applied in coatings, non-woven fabrics, electrospinning, etc., can solve the problems of poor low-frequency sound-absorbing effect, achieve low environmental pollution, easy preparation, and improve mid-low frequency sound-absorbing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

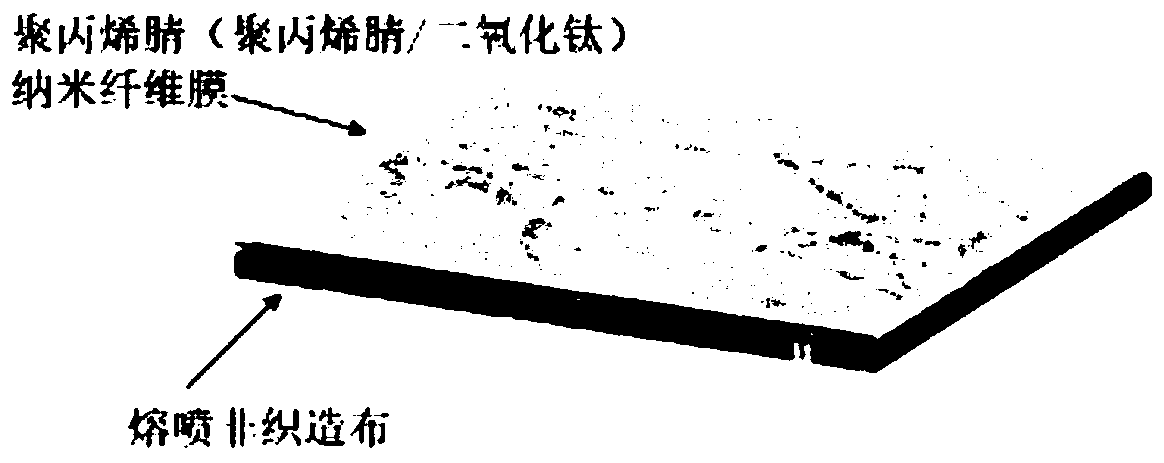

[0028] A lightweight medium-low frequency sound-absorbing material and its preparation method:

[0029] Step (1): prepare polyacrylonitrile spinning solution, polyacrylonitrile is added in N,N-dimethylformamide, wherein, the concentration of polyacrylonitrile is respectively 6wt% (such as N,N-dimethylformamide If the amide is 4.7g, then add polyacrylonitrile (0.3g), stir magnetically for 20-24h, and obtain a uniform solution;

[0030] Step (2): Electrospinning is performed on the base of the nonwoven fabric: the applied voltage is 10 kV, the spinning speed is 1 mL / h, and the spinning distance is 12 cm.

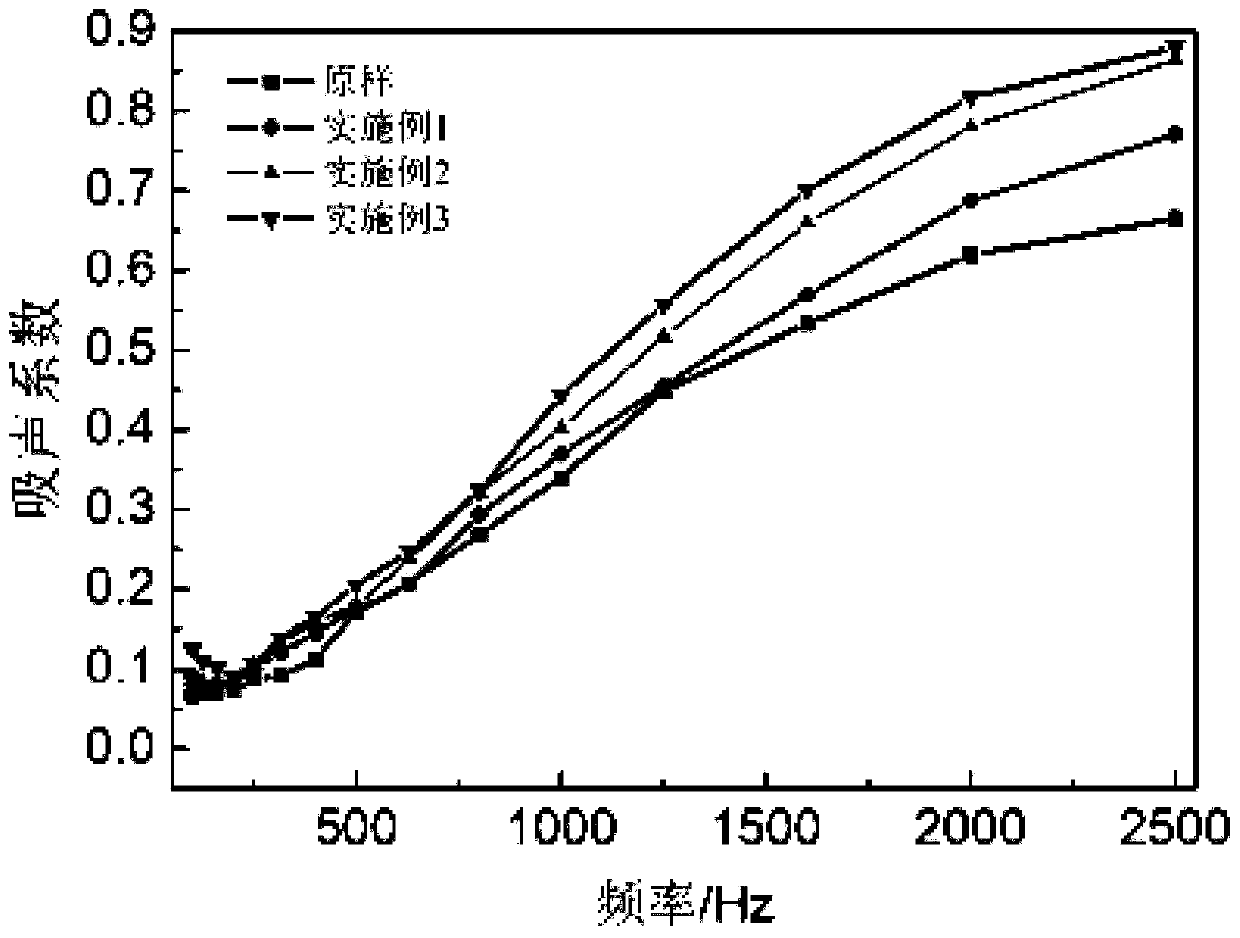

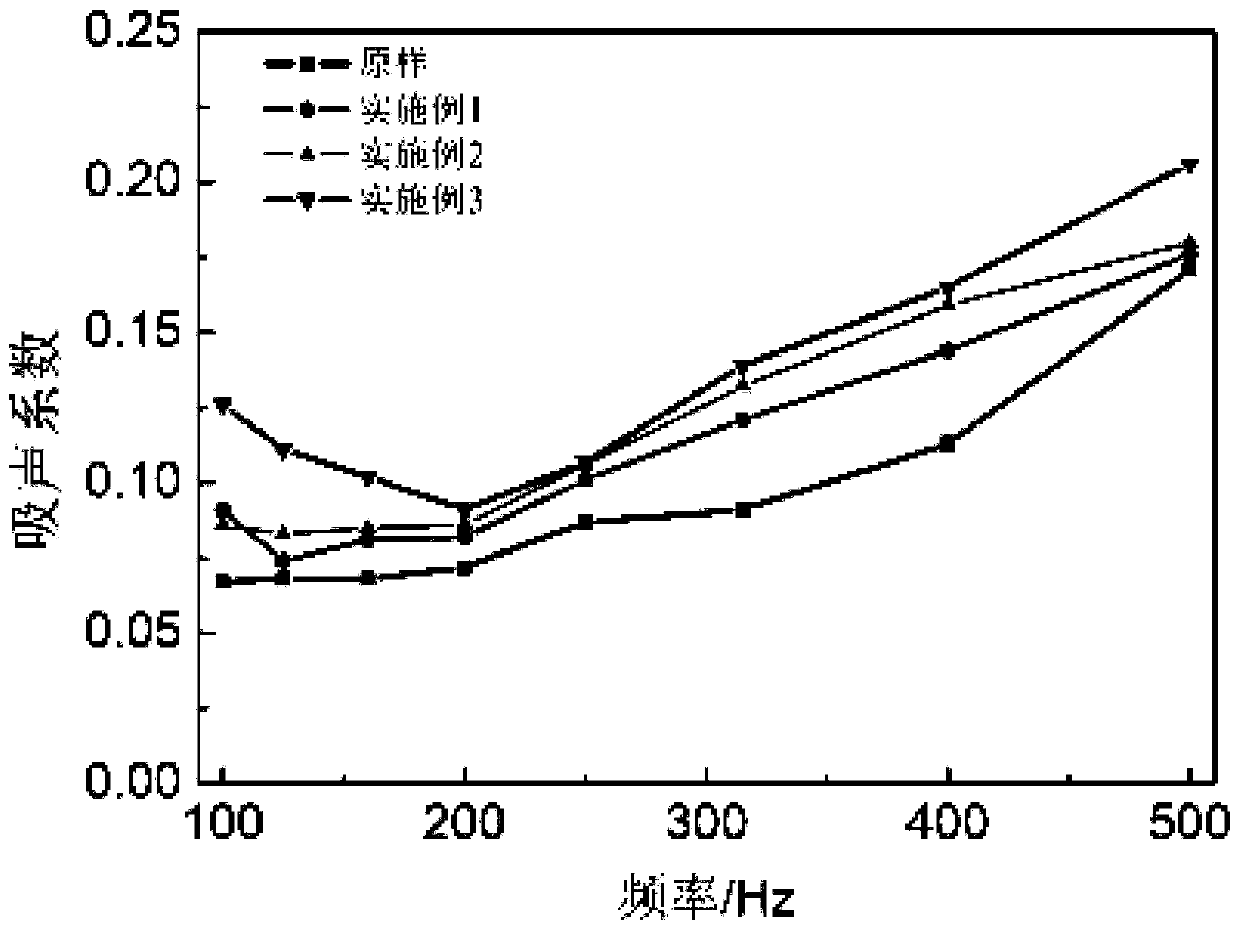

[0031] Step (3): dry treatment at room temperature to obtain a nanofiber composite nonwoven fabric sound-absorbing material; the sound absorption coefficient is as follows figure 2 (100-2500Hz), image 3 (100-500Hz) shown.

Embodiment 2

[0033] A lightweight medium-low frequency sound-absorbing material and its preparation method:

[0034] Step (1): prepare polyacrylonitrile spinning solution, polyacrylonitrile is added in N,N-dimethylformamide, wherein, the concentration of polyacrylonitrile is respectively 8wt% (such as N,N-dimethylformamide If the amide is 4.6g, then add polyacrylonitrile (0.4g), stir magnetically for 20-24h, and obtain a uniform solution;

[0035] Step (2): Electrospinning is performed on the base of the nonwoven fabric: the applied voltage is 10 kV, the spinning speed is 1 mL / h, and the spinning distance is 12 cm.

[0036] Step (3): dry treatment at room temperature to obtain a nanofiber composite nonwoven fabric sound-absorbing material; the sound absorption coefficient is as follows figure 2 (100-2500Hz), image 3 (100-500Hz) shown.

Embodiment 3

[0038] A lightweight medium-low frequency sound-absorbing material and its preparation method:

[0039] Step (1): prepare polyacrylonitrile spinning solution, polyacrylonitrile is added in N,N-dimethylformamide, wherein, the concentration of polyacrylonitrile is respectively 10wt% (such as N,N-dimethylformamide If the amide is 4.5g, then add polyacrylonitrile (0.5g), stir magnetically for 20-24h, and obtain a uniform solution;

[0040] Step (2): Electrospinning is performed on the base of the nonwoven fabric: the applied voltage is 10 kV, the spinning speed is 1 mL / h, and the spinning distance is 12 cm.

[0041] Step (3): dry treatment at room temperature to obtain a nanofiber composite nonwoven fabric sound-absorbing material; the sound absorption coefficient is as follows figure 2 (100-2500Hz), image 3 (100-500Hz) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com