Lead electrolyte purification process

A purification process and lead electrolyte technology, applied in the field of lead electrolytic refining, to achieve good purification effect and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

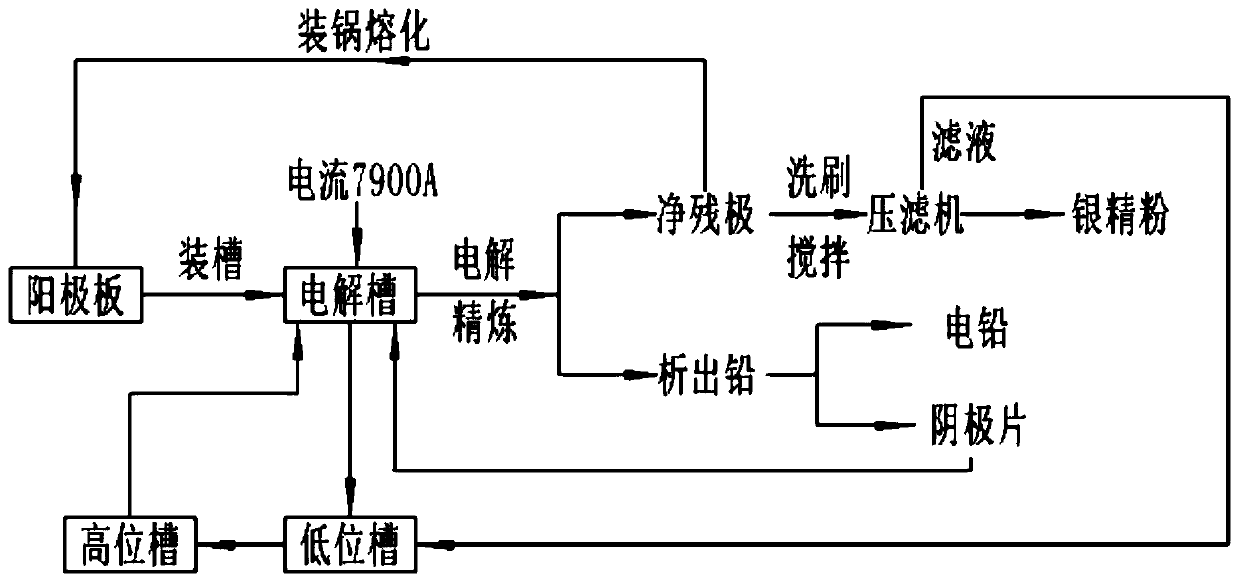

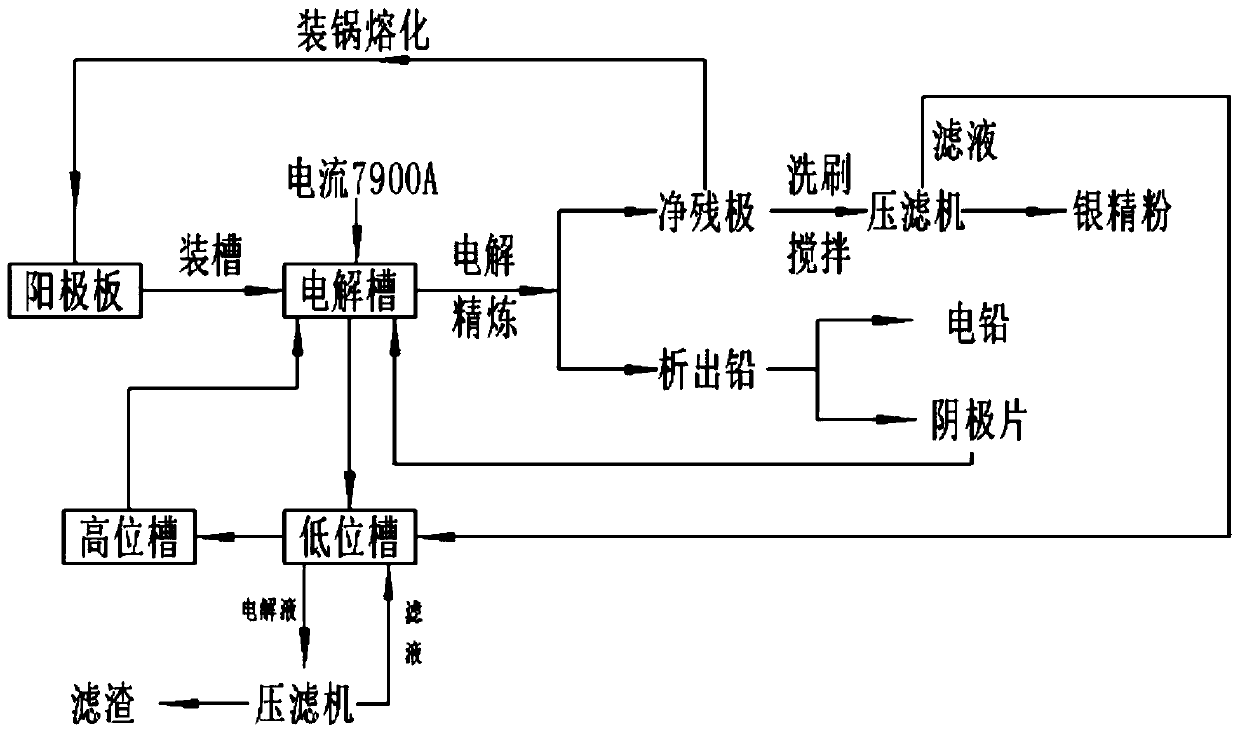

Method used

Image

Examples

Embodiment 1

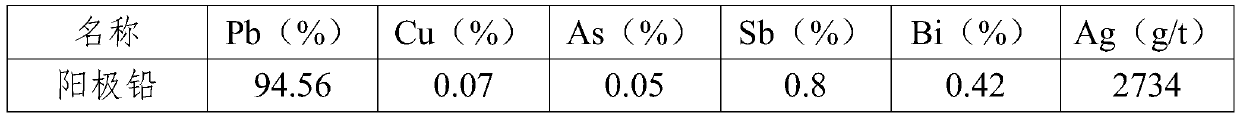

[0029] After testing, the concentration of impurity metal ions in the electrolyte to be purified: Cu=1.42mg / L, As=875mg / L, Sb=645mg / L, Bi=25mg / L, Ag=2.1g / t.

[0030] The above electrolytic solution is subjected to the following purification process: use a filter press equipped with a 600-mesh anti-fluosilicate filter cloth to filter and remove impurities. The filter area of the filter press is 20m 2 , the number of matching plates is 19 pieces, the pressing pressure is 19Mpa, the back pressure is 30Mpa, and the filtration pressure is 8kg / cm 2 . The auxiliary equipment includes: three-phase motor, hydraulic station, YDS low-speed motor. In addition, a new circulating pump used in conjunction with the filter press: the flow rate is 10m 3 / h, the head is 80m, the speed is 2900r / min, and the power is 18.9KW. Auxiliary equipment: three-phase asynchronous motor 18KW.

[0031] After 8 hours, the concentration of impurity metal ions in the purified electrolyte was detected, and...

Embodiment 2

[0033] After testing, the concentration of impurity metal ions in the electrolyte to be purified: Cu=1.65mg / L, As=1050mg / L, Sb=380mg / L, Bi=7.3mg / L, Ag=4.2g / t.

[0034] The above electrolytic solution is subjected to the following purification process: use a filter press equipped with an 800-mesh anti-fluosilicate filter cloth to filter and remove impurities. The filter area of the filter press is 20m 2 , the number of matching plates is 19 pieces, the pressing pressure is 19Mpa, the back pressure is 30Mpa, and the filtration pressure is 8kg / cm 2 . The auxiliary equipment includes: three-phase motor, hydraulic station, YDS low-speed motor. In addition, two new circulating pumps are added to be used with the filter press: the flow rate is 10m 3 / h, the head is 80m, the speed is 2900r / min, and the power is 18.9KW. Auxiliary equipment: three-phase asynchronous motor 18KW.

[0035] After 8 hours, the concentration of impurity metal ions in the purified electrolyte was detect...

Embodiment 3

[0037] After testing, the concentration of impurity metal ions in the electrolyte to be purified: Cu=1.60mg / L, As=680mg / L, Sb=650mg / L, Bi=36mg / L, Ag=3.1g / t.

[0038] The above electrolytic solution is subjected to the following purification process: use a filter press equipped with a 1000-mesh anti-fluosilicate filter cloth to filter and remove impurities. The filter area of the filter press is 20m 2 , the number of matching plates is 19 pieces, the pressing pressure is 19Mpa, the back pressure is 30Mpa, and the filtration pressure is 8kg / cm 2 . The auxiliary equipment includes: three-phase motor, hydraulic station, YDS low-speed motor. In addition, two new circulating pumps are added to be used with the filter press: the flow rate is 10m 3 / h, the head is 80m, the speed is 2900r / min, and the power is 18.9KW. Auxiliary equipment: three-phase asynchronous motor 18KW.

[0039] After 8 hours, the concentration of impurity metal ions in the purified electrolyte was detected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com