Vehicle primary oil and production method thereof

A production method and primary oil technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel additives, etc., can solve the problems of complex manufacturing process of primary oil, easy to change performance, no corrosion resistance, etc., to achieve convenient The effect of long-term storage and use, stable performance, excellent anti-oxidation and anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

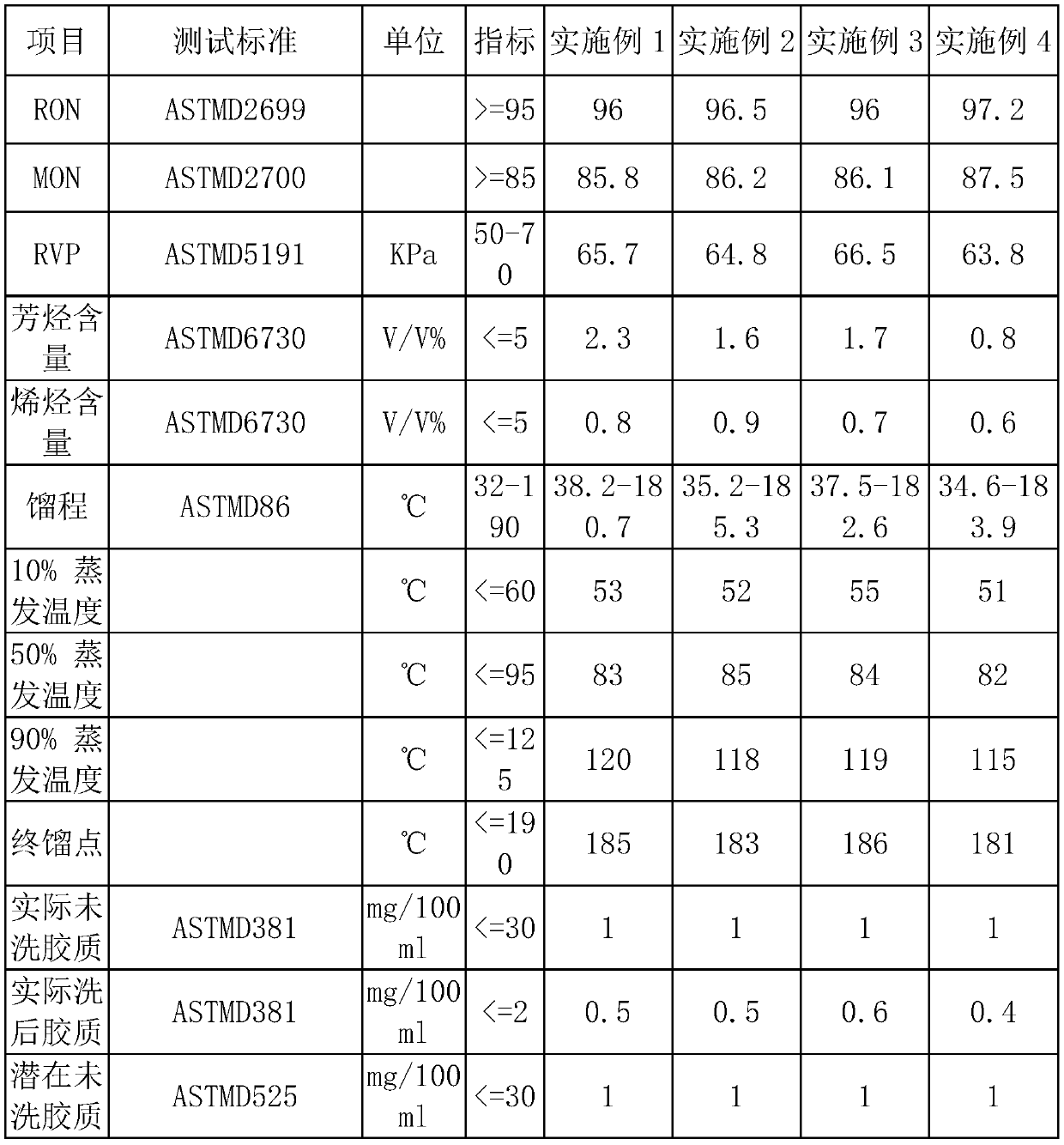

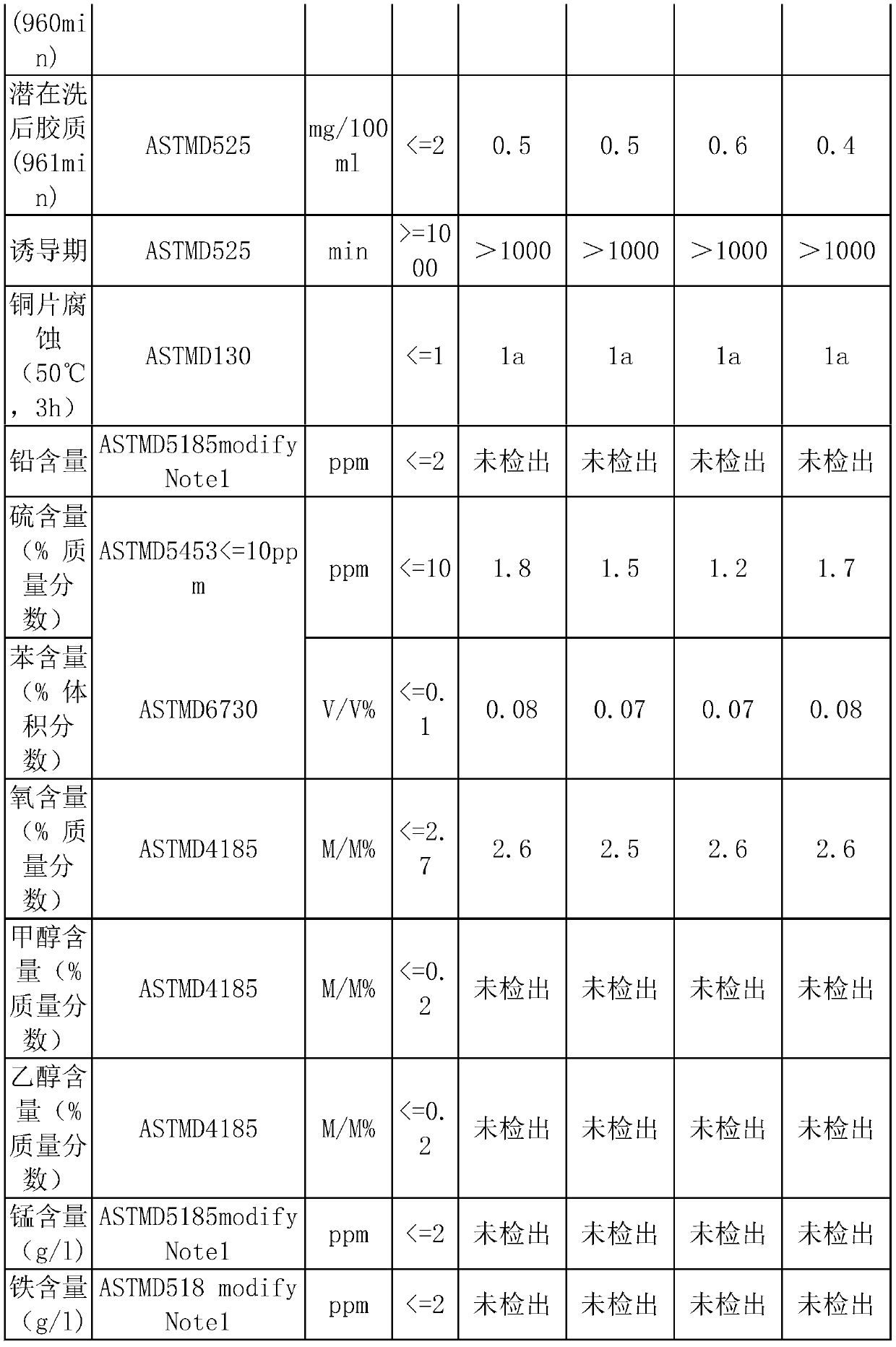

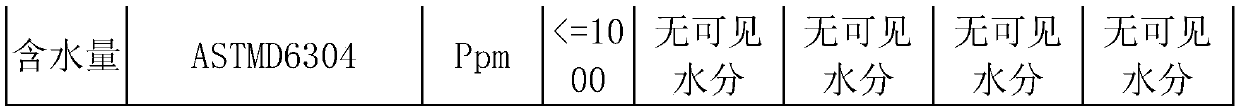

Examples

Embodiment 1

[0019] Take 69 parts of isooctane as raw material, 3 parts of benzene raffinate, 12 parts of methyl tert-butyl ether, 15 parts of isopentane and 1 part of primary oil additive, and produce primary oil according to the following production steps:

[0020] Step 1: Weigh the above raw materials and add them to the blending tank, turn on the circulating pump, and then pump in isopentane, raffinate, methyl tert-butyl ether, isopentane and initial oil additives in sequence, and add all of them Then continue to circulate for 1 hour and mix evenly to obtain the finished product initial oil;

[0021] Step 2: Measure the saturated vapor pressure and distillation range of the finished oil, and judge whether it falls within the control range of the index, that is, the saturated vapor pressure is 50-70kPa, and the distillation range is 32-190°C; if not The detection index, that is, the circulation pump needs to be turned on again, and the mixing is carried out again until the detection ind...

Embodiment 2

[0024] Take 72 parts of isooctane as raw material, 2 parts of benzene raffinate, 14 parts of methyl tert-butyl ether, 10 parts of isopentane and 2 parts of primary oil additives, and produce primary oil according to the following production steps:

[0025] Step 1: Weigh the above raw materials and add them to the blending tank, turn on the circulating pump, and then pump in isopentane, raffinate, methyl tert-butyl ether, isopentane and initial oil additives in sequence, and add all of them Then continue to circulate for 1 hour and mix evenly to obtain the finished product initial oil;

[0026] Step 2: Measure the saturated vapor pressure and distillation range of the finished oil, and judge whether it falls within the control range of the index, that is, the saturated vapor pressure is 50-70kPa, and the distillation range is 32-190°C; if not The detection index, that is, the circulation pump needs to be turned on again, and the mixing is carried out again until the detection i...

Embodiment 3

[0029] Take 62 parts of raw material isooctane, 2 parts of benzene raffinate, 13 parts of methyl tert-butyl ether, 20 parts of isopentane and 3 parts of primary oil additives, and produce primary oil according to the following production steps:

[0030] Step 1: Weigh the above raw materials and add them to the blending tank, turn on the circulating pump, and then pump in isopentane, raffinate, methyl tert-butyl ether, isopentane and initial oil additives in sequence, and add all of them Then continue to circulate for 1 hour and mix evenly to obtain the finished product initial oil;

[0031] Step 2: Measure the saturated vapor pressure and distillation range of the finished oil, and judge whether it falls within the control range of the index, that is, the saturated vapor pressure is 50-70kPa, and the distillation range is 32-190°C; if not The detection index, that is, the circulation pump needs to be turned on again, and the mixing is carried out again until the detection inde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com