DOP-free rubber and plastic product and preparation method thereof

A technology of rubber and plastic products and nitrile rubber, which is applied in the field of DOP-free rubber and plastic products and its preparation, can solve the problems of poor comprehensive performance of DOP-free rubber, achieve the goals of reducing solvent extraction rate, improving compatibility and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

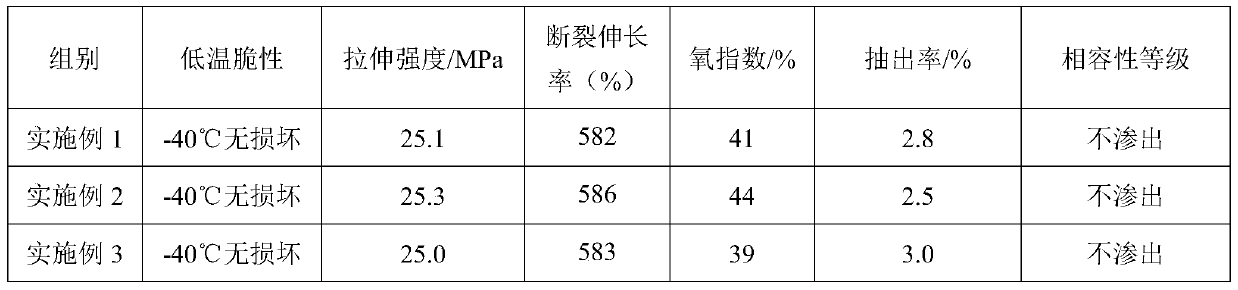

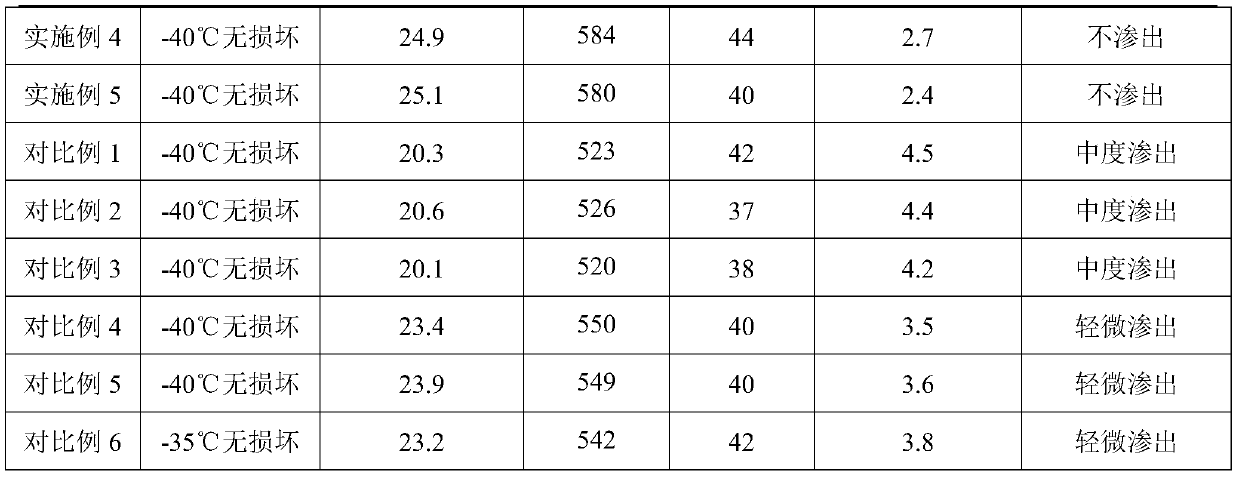

Examples

Embodiment 1

[0024] A DOP-free rubber and plastic product, comprising 15 parts by mass of nitrile rubber, 7 parts of polyvinyl chloride resin, 3 parts of ethylene-vinyl acetate copolymer, 30 parts of talcum powder, 13 parts of chlorinated paraffin oil, 2 parts of epoxy soybean oil, 2 parts of protective wax, 5 parts of white carbon black, 0.2 parts of active agent, 0.3 parts of stearic acid, 10 parts of flame retardant, 0.3 parts of anti-aging agent, 1 part of accelerator, 0.3 parts of sulfur, ethylene glycol 0.5 parts of sodium di-o-phenyl acetate, 1.2 parts of sodium diamyl sulfosuccinate, 1 part of di-n-butylamine, and 1.5 parts of cyclopentylamine.

[0025] The accelerator is N-cyclohexyl-2-benzothiazole sulfenamide; the flame retardant is antimony trioxide; the active agent is magnesium oxide; the protective wax is paraffin; the antiaging agent is N-phenyl-2-naphthalene amine.

[0026] The preparation method of above-mentioned DOP-free rubber and plastic product, comprises the follow...

Embodiment 2

[0032] A DOP-free rubber and plastic product, comprising 17 parts by mass of nitrile rubber, 6.5 parts of polyvinyl chloride resin, 3.5 parts of vinyl acetate copolymer, 28 parts of talcum powder, 13.5 parts of chlorinated paraffin oil, epoxy 1.5 parts of soybean oil, 3 parts of protective wax, 4 parts of white carbon black, 0.25 parts of active agent, 0.2 parts of stearic acid, 15 parts of flame retardant, 0.2 parts of anti-aging agent, 1.5 parts of accelerator, 0.2 parts of vulcanizing agent, ethylenediamine 0.6 parts of sodium di-o-phenyl acetate, 0.9 parts of sodium diamyl sulfosuccinate, 1.5 parts of di-n-butylamine, and 1.2 parts of cyclopentylamine.

[0033] The accelerator is N-cyclohexyl-2-benzothiazole sulfenamide; the flame retardant is antimony trioxide and aluminum hydroxide with a mass ratio of 1:1; Magnesium, calcium oxide; protective wax is polyethylene wax; anti-aging agent is 6-dodecyl-2,2,4-trimethyl-1,2-dihydroquinoline.

[0034] The preparation method of ...

Embodiment 3

[0040] A DOP-free rubber and plastic product, comprising 20 parts by mass of nitrile rubber, 5 parts of polyvinyl chloride resin, 5 parts of ethylene-vinyl acetate copolymer, 20 parts of talcum powder, 15 parts of chlorinated paraffin oil, 1 part of epoxy soybean oil, 4 parts of protective wax, 3 parts of white carbon black, 0.3 parts of active agent, 0.1 part of stearic acid, 20 parts of flame retardant, 0.1 part of anti-aging agent, 3 parts of accelerator, 0.1 part of sulfur, ethylene glycol 1 part of sodium di-o-phenyl acetate, 0.8 part of sodium diamyl sulfosuccinate, 2 parts of di-n-butylamine, and 1 part of cyclopentylamine.

[0041] The accelerator is N-cyclohexyl-2-benzothiazole sulfenamide; the flame retardant is selected from aluminum hydroxide; the active agent is zinc stearate; the protective wax is mixed crystal wax; -Dioctyldiphenylamine.

[0042] The preparation method of above-mentioned DOP-free rubber and plastic product, comprises the following steps:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com