A kind of preparation method and application of cationic surfactant

A surfactant, cationic technology, applied in the direction of cationic surface active compounds, surface active detergent compositions, polymer surface active compounds, etc., can solve the loss of the ability to capture dyes, affect the detergency of detergents, and has never been reported. Modified cellulose and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

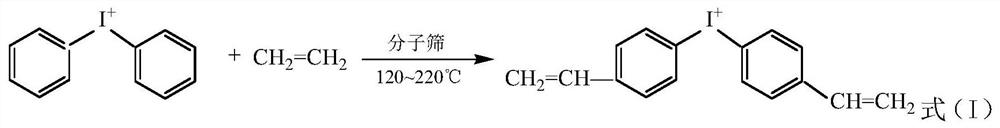

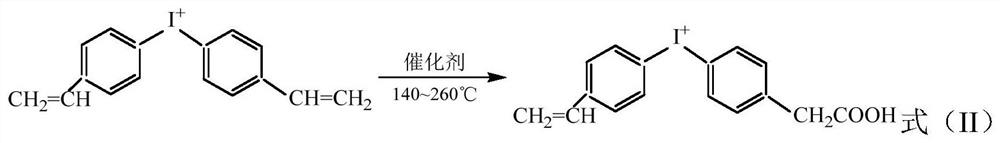

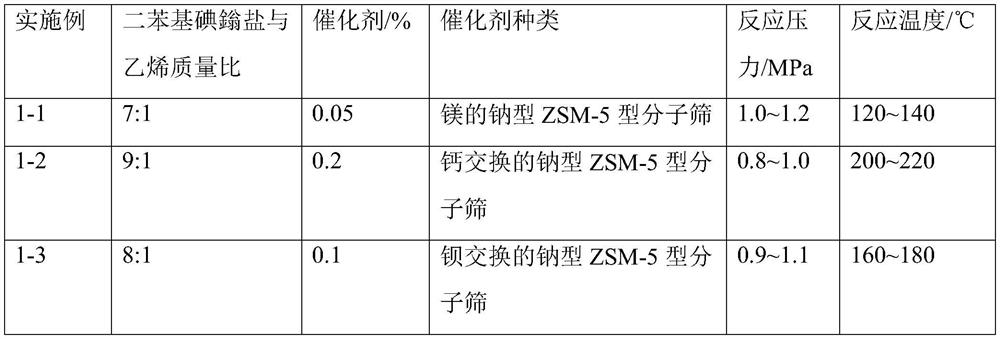

Method used

Image

Examples

Embodiment 2-1

[0033] 1. Synthesis of (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone

[0034] The monomer vinylpyrrolidone (NVP) is configured into an aqueous solution with a mass fraction of 45%, using a small amount of hydrogen peroxide (0.2% of NVP) as a catalyst, under the action of azobisisobutyronitrile (0.3% of NVP), in Initiate polymerization at 40-50°C, react for 2 hours, and the monomer polymerization conversion rate is 93-95%. Add the (4-vinylphenyl-4'-methylenecarboxyphenyl) iodonium (0.5% NVP) prepared in Example 1-1, react for 0.2 hours, and cap the polymer, (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone is obtained.

[0035] Then add 0.2% ammonia water to the polymer to decompose the remaining azobisisobutyronitrile. The polymer is spray-dried under hot air at 120-135°C to obtain powdery (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone. (4-vinylphenyl-4'-methylenecarboxy...

Embodiment 2-2

[0046] 1. Synthesis of (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone

[0047] The monomer vinylpyrrolidone (NVP) was configured into an aqueous solution with a mass fraction of 50%. Use a small amount of hydrogen peroxide (0.3% NVP) as a catalyst, under the action of azobisisobutyronitrile (0.4% NVP), initiate polymerization at 50-60°C, react for 3 hours, and the monomer polymerization conversion rate is 96~98%.Add (4-vinylphenyl-4-methylenecarboxyphenyl) iodonium (consumption is 0.8% NVP) that embodiment 1-1 makes, react 0.5 hour, to polymer Capping is performed to obtain (4-vinylphenyl-4-methylenecarboxyphenyl)iodonium-blocked polyvinylpyrrolidone.

[0048] Add 0.3% ammonia water to the polymer to decompose the remaining azobisisobutyronitrile. The polymer is spray-dried under hot air at 135-150°C to obtain powdery (4-vinylphenyl-4-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone. (4-vinylphenyl-4'-methylenecarboxypheny...

Embodiment 2-3

[0054] 1. Synthesis of (4-vinylphenyl-4'-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone

[0055] The monomer vinylpyrrolidone (NVP) was configured into an aqueous solution with a mass fraction of 55%. Use a small amount of hydrogen peroxide (0.4% NVP) as a catalyst, under the action of azobisisobutyronitrile (0.5% NVP), initiate polymerization at 60-70 ° C, react for 4 hours, the monomer polymerization conversion rate is 97 ~99%. Add the (4-vinylphenyl-4-methylenecarboxyphenyl) iodonium (amount of 1% NVP) obtained in Example 1-2, react for 0.6 hours, and cap the polymer to obtain (4-vinylphenyl-4-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone.

[0056] Add 0.4% ammonia water to the polymer to decompose the remaining azobisisobutyronitrile. The polymer is spray-dried under hot air at 150-165°C to obtain powdery (4-vinylphenyl-4-methylenecarboxyphenyl)iodonium-terminated polyvinylpyrrolidone. (4-vinylphenyl-4'-methylenecarboxyphenyl) iodon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com