A timber loading device in forestry development

A shipping device and wood technology, applied in the direction of vehicles for carrying long goods, etc., can solve the problems of not getting up and down, increasing the difficulty of transportation, and prone to jamming, etc., to facilitate transportation, prevent jamming, and facilitate clamping. tightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

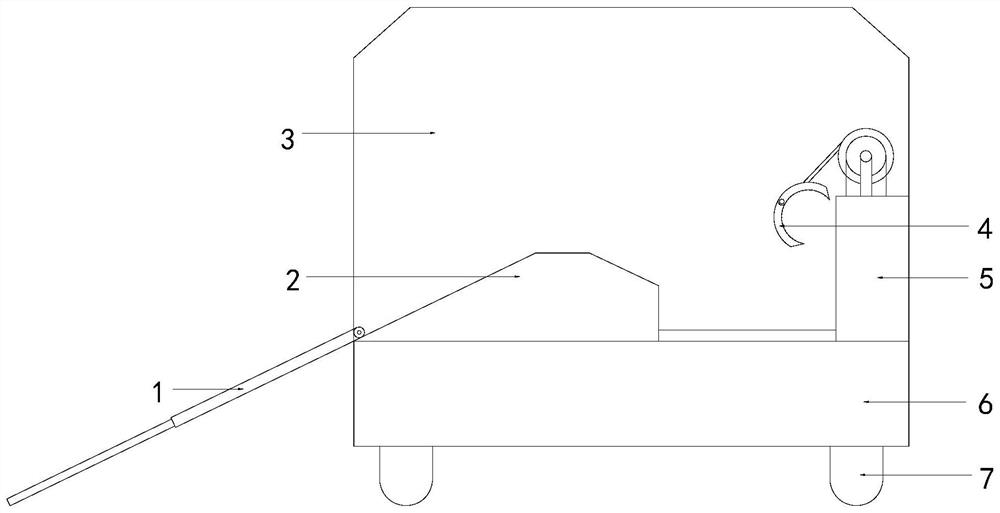

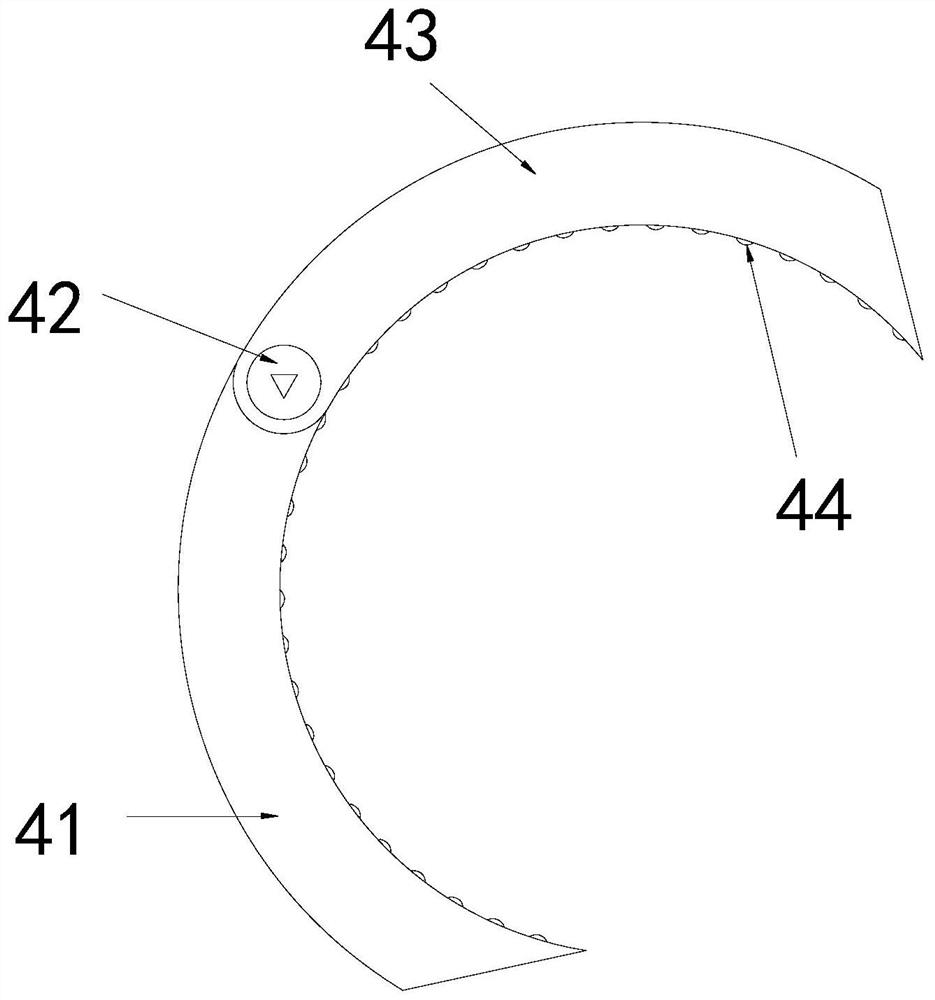

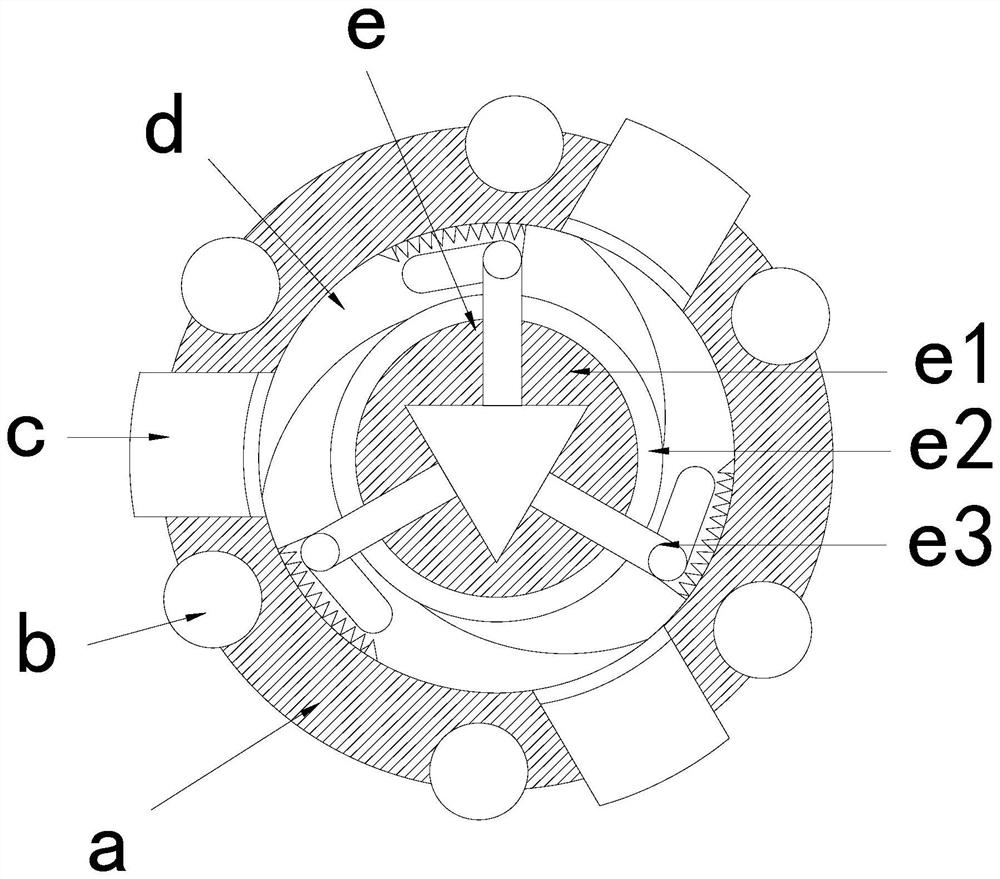

[0029] see Figure 1-6 , the present invention provides a technical scheme of a timber shipping device in forestry development: its structure includes a hinged plate 1, a guide slide 2, a headstock 3, a hook 4, a power box 5, a carriage 6, and wheels 7, and the back of the headstock 3 is connected to There is a compartment 6, the bottom of the compartment 6 is provided with wheels 7, and the two sides of the top of the compartment 6 are respectively provided with a power box 5 and a guide slide 2, the guide slide 2 is hinged with the hinge plate 1, and the hook 4 Connected with the power box 5, the hook 4 includes a first splint 41, a hinge shaft 42, a second splint 43, and a ball 44, and the first splint 41 and the second splint 43 are flexibly connected by the hinge shaft 42, so The inner sides of the first splint 41 and the second splint 43 are provided with uniformly distributed balls 44. The hinged shaft 42 includes a shaft body a, a small ball b, a brake block c, a groov...

Embodiment 2

[0032] see Figure 1-6 , the present invention provides a technical scheme of a timber shipping device in forestry development: its structure includes a hinged plate 1, a guide slide 2, a headstock 3, a hook 4, a power box 5, a carriage 6, and wheels 7, and the back of the headstock 3 is connected to There is a compartment 6, the bottom of the compartment 6 is provided with wheels 7, and the two sides of the top of the compartment 6 are respectively provided with a power box 5 and a guide slide 2, the guide slide 2 is hinged with the hinge plate 1, and the hook 4 Connected with the power box 5, the hook 4 includes a first splint 41, a hinge shaft 42, a second splint 43, and a ball 44, and the first splint 41 and the second splint 43 are flexibly connected by the hinge shaft 42, so The inner sides of the first splint 41 and the second splint 43 are provided with uniformly distributed balls 44. The hinged shaft 42 includes a shaft body a, a small ball b, a brake block c, a groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com