Rapid evaluation method for shale oil saturation well site

An evaluation method and saturation technology, applied in water resource evaluation, suspension and porous material analysis, analysis using nuclear magnetic resonance, etc. The effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The rapid evaluation method for oil saturation of shale oil well site, this scheme includes the following steps: the present invention is aimed at the core just out of the barrel at the drilling site, but it is not limited to the site, and can also be realized in the laboratory.

[0048] S1: Sampling: After the core comes out of the barrel, take a sample at the center of the core; the test sample mass is 12.69g.

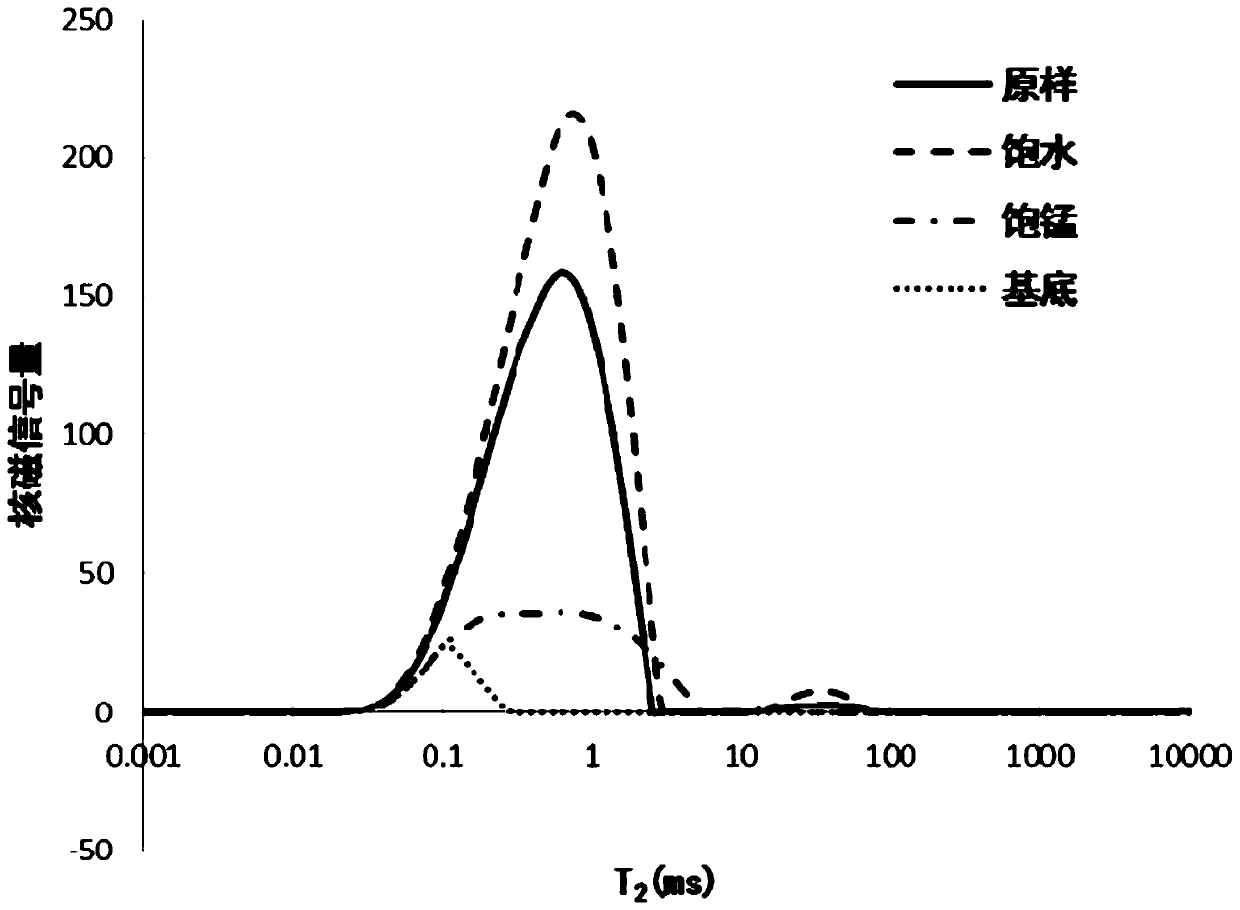

[0049] S2: Use the MicroMTR20-025V desktop low-field high-frequency (18MHz) NMR instrument to sequentially measure the one-dimensional NMR signals of the samples in the three states of massive ground original, massive self-priming saturated water, and frozen crushed manganese-saturated samples:

[0050] S2.1: Design and debug instrument parameters for shale, configure simulated formation water according to the analysis data of adjacent wells in the region; calibrate the oil and water signals by adjacent well crude oil and simulated formation water, and determin...

Embodiment 2

[0076] The rapid evaluation method for oil saturation of shale oil well site, this scheme includes the following steps: the present invention is aimed at the core just out of the barrel at the drilling site, but it is not limited to the site, and can also be realized in the laboratory.

[0077] S1: Sampling: After the core is out of the barrel, take a sample at the center of the core; the mass of the test sample is 9.13g.

[0078] S2: Use the MicroMTR20-025V desktop low-field high-frequency (18MHz) NMR instrument to sequentially measure the one-dimensional NMR signals of the samples in the three states of massive ground original, massive self-priming saturated water, and frozen crushed manganese-saturated samples:

[0079] S2.1: Design and debug instrument parameters for shale, configure simulated formation water according to the analysis data of adjacent wells in the region; calibrate the oil and water signals by adjacent well crude oil and simulated formation water, and deter...

Embodiment 3

[0105] The rapid evaluation method for oil saturation of shale oil well site, this scheme includes the following steps: the present invention is aimed at the core just out of the barrel at the drilling site, but it is not limited to the site, and can also be realized in the laboratory.

[0106] S1: Sampling: After the core comes out of the barrel, take a sample at the center of the core; the mass of the test sample is 16.13g.

[0107] S2: Use the MicroMTR20-025V desktop low-field high-frequency (18MHz) NMR instrument to sequentially measure the one-dimensional NMR signals of the samples in the three states of massive ground original, massive self-priming saturated water, and frozen crushed manganese-saturated samples:

[0108] S2.1: Design and debug instrument parameters for shale, configure simulated formation water according to the analysis data of adjacent wells in the region; calibrate the oil and water signals by adjacent well crude oil and simulated formation water, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com